LF composite deoxidization reducer

A technology of composite deoxidation and reducing agent, applied in the field of LF composite deoxidizing and reducing agent, can solve the problem that the deoxidation effect, desulfurization ability and the ability of adsorbing inclusions cannot meet the high performance requirements of molten steel smelting, etc., to reduce labor intensity and environmental pollution, The effect of reducing alloy consumption and having broad application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

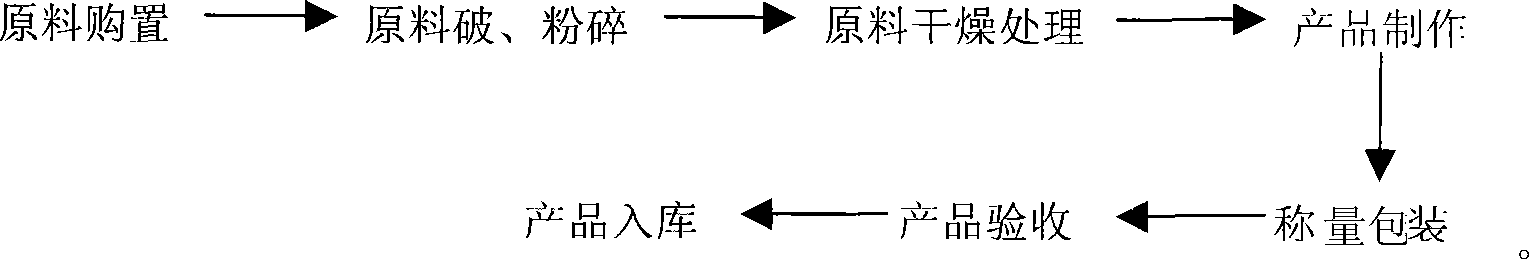

Method used

Image

Examples

Embodiment Construction

[0024] The present invention is described in detail below in conjunction with embodiment.

[0025] This product is composed of four raw materials: aluminum particles (Al), silicon calcium barium alloy (SiCaBa), silicon carbide (SiC) and graphite. The mixture formed by mixing the four raw materials contains five elements Ca, Ba, C, Al and Si, the mass percentages of these five elements in the mixture are Ca 1-5%, Ba 2-7%, C 15-45%, Al 5-30%, and Si 20-55%. The preferred percentages are: Ca 1-2.5%, Ba 2-5.5%, C 25-45%, Al 10-30%, Si 20-45%. More preferable percentages are 1 to 1.5% of Ca, 2 to 3.5% of Ba, 35 to 45% of C, 20 to 30% of Al, and 20 to 30% of Si. By the above-mentioned percentages of the five elements, the respective percentages of each raw material in the mixture can be deduced according to the purity of the four raw materials, thereby converting the percentages of the five elements that affect the effect of the present invention into four The percentage of each r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com