Sodium hydrogen carbonate injection plastic package and production method thereof

A sodium bicarbonate and plastic packaging technology, applied in the field of pharmaceutical packaging, can solve the problems of sodium bicarbonate injection pH value change, poor gas barrier performance, etc., and achieve the effect of facilitating production and ensuring stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

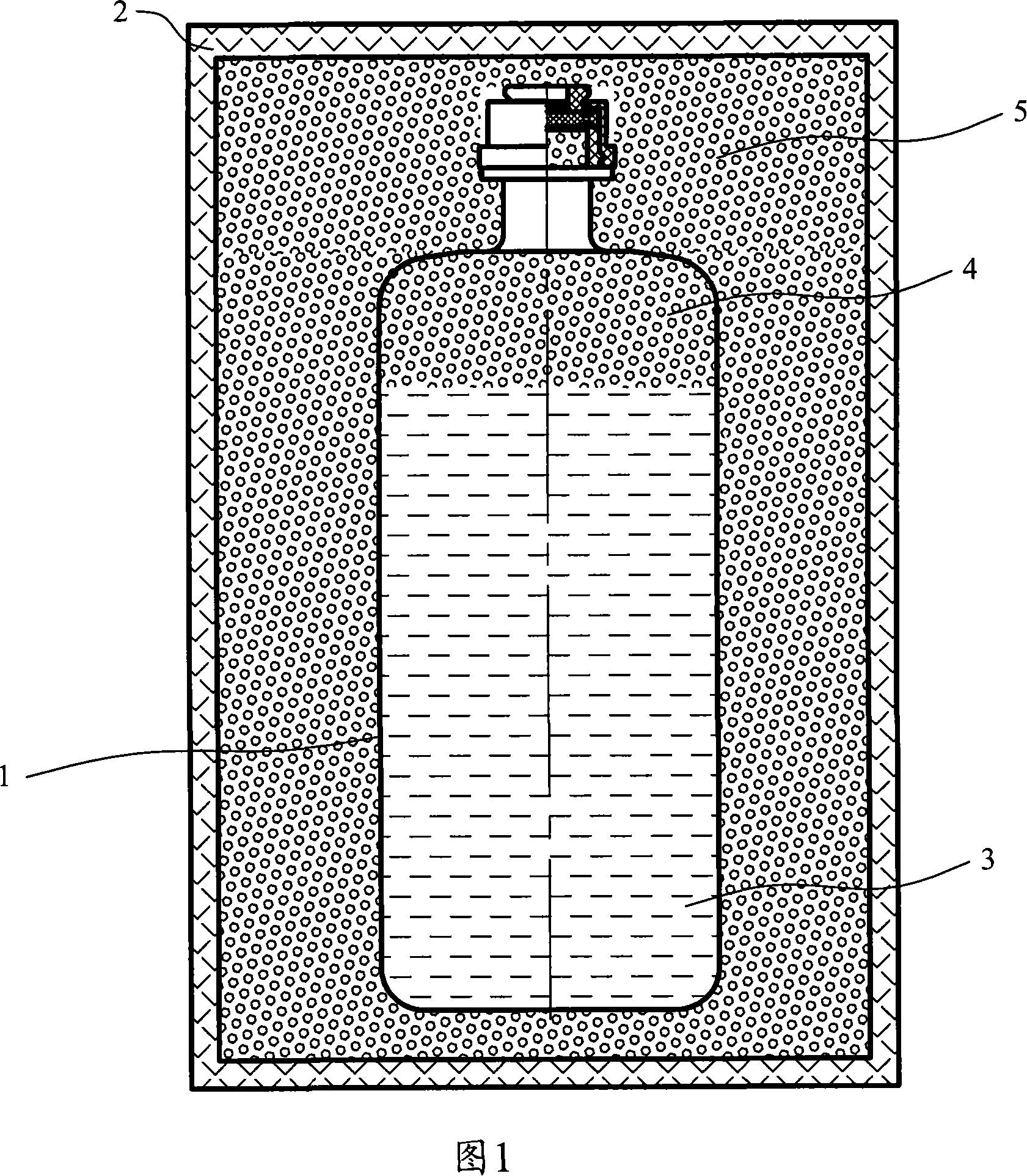

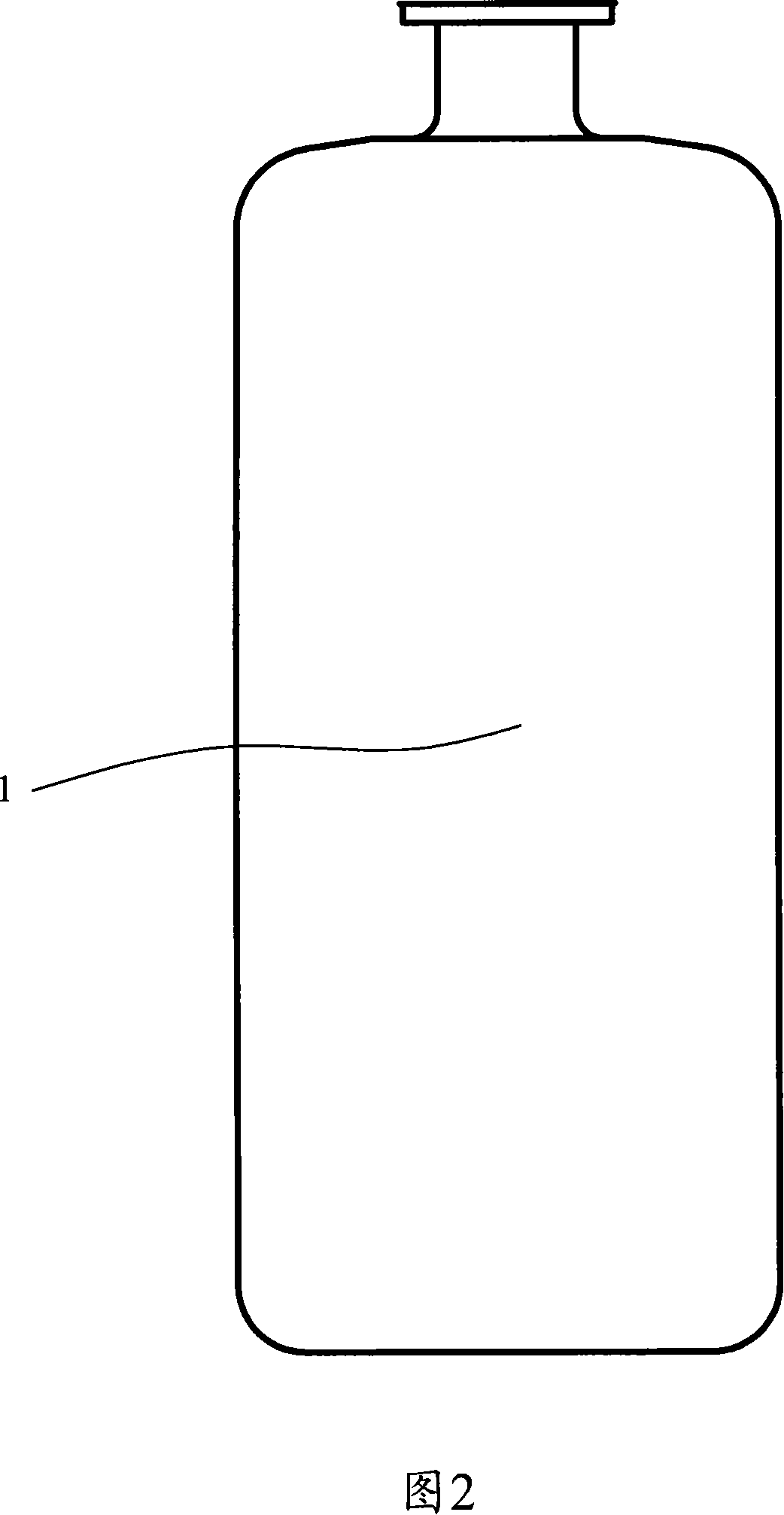

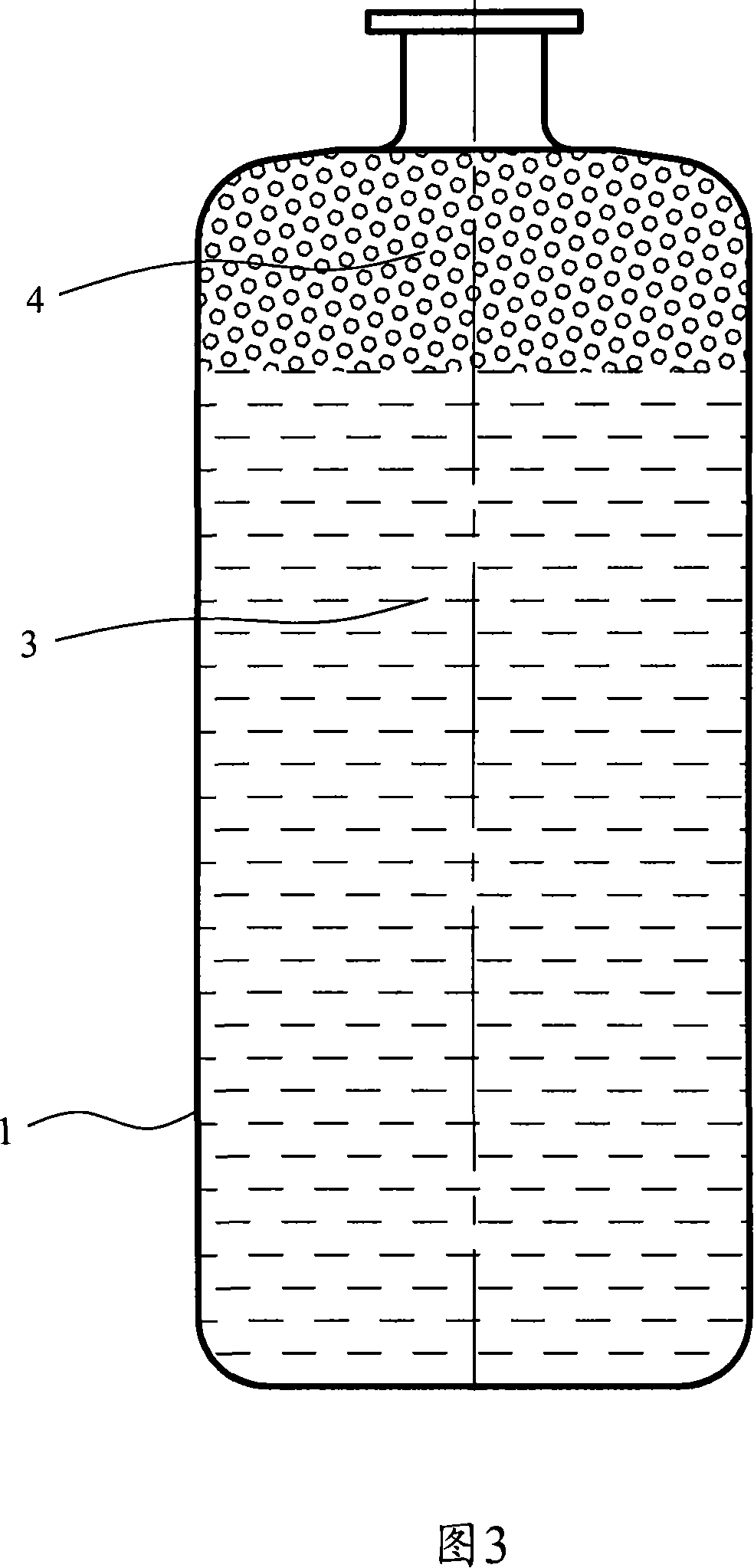

[0059] First make the plastic bottle 1 as shown in Figure 2; After the plastic bottle is cleaned, the sodium bicarbonate injection 3 prepared is poured in the plastic bottle 1; Fill the carbon dioxide gas 4 while filling the medicinal liquid, As shown in Figure 3; The plastic bottle that filling medicinal liquid and be full of carbon dioxide gas 4 is sealed with combination cap 12 afterwards, as shown in Figure 4; In the protective bag 2, and before sealing, the air in the bag is drawn out and filled with carbon dioxide gas 5, as shown in Figure 1; Packing can be done after passing the test.

Embodiment 2

[0061] First make the plastic inner bag 6 as shown in Figure 6; Fill the sodium bicarbonate injection 3 prepared in the plastic inner bag 6; Fill into carbon dioxide gas 4 while filling the medicinal liquid, as shown in Figure 7 ; Use combination cover 12 to be filled with liquid medicine and be full of the plastic inner bag 6 sealing of carbon dioxide gas 4 afterwards, as shown in Figure 8; Protect the bag 2, and before sealing, the air in the bag is drawn out and filled with carbon dioxide gas 5, as shown in Figure 5; the package shown in Figure 5 is sterilized at high temperature, and then the sterilized product is passed the light inspection Then pack it.

Embodiment 3

[0063] First make the plastic bottle 1 shown in Figure 2; after the plastic bottle is cleaned, pour the sodium bicarbonate injection 3 prepared in the plastic bottle 1; fill the carbon dioxide gas 4 while filling the medicinal liquid 3; use combination cover 12 to be filled with medicinal liquid and be full of the plastic bottle of carbon dioxide gas 4 to seal afterwards, as shown in Figure 4; Plastic bottle shown in Figure 4 is carried out high-temperature sterilization; Plastic after sterilization The bottle is sealed in a protective bag 2 made of a high gas barrier film, and before sealing, the air in the bag is drawn out and filled with carbon dioxide gas 5, as shown in Figure 1. Pack the product as shown in Figure 1 after passing the light inspection.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com