PET/Attapulgite nano composite fiber

A technology of nano-composite fibers and attapulgite, which is applied in directions such as single-component polyester rayon filaments, can solve problems such as reduced mechanical properties, and achieve the effects of convenient operation, improved breaking strength and simple preparation process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

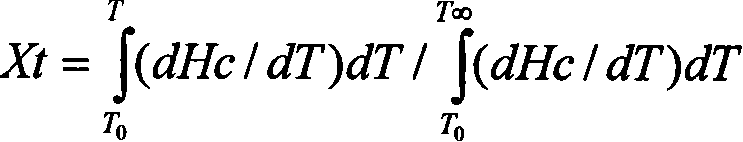

[0022] The dry slices of the PET / attapulgite composite material with an attapulgite content of 0.02% are spun and drawn by MST C-TYPE small spinning equipment and a parallel drafting machine to obtain PET / attapulgite nanocomposite fibers. The spinning temperature is controlled to be 290° C., and the draw ratio is 3 times. Test the obtained PET / attapulgite nanocomposite fiber, wherein, the time required for crystallization is t 1 / 2 It is expressed as the time required for the volume shrinkage of the polymer melt to reach half of the entire process during the cooling process. After the fiber sample is heated and melted by DSC (differential scanning calorimeter), it is then cooled at a rate of 10°C / min. rate cooling, recording the change in enthalpy during the process, via the equation Xt = ∫ T 0 T ( dHc / dT ) ...

Embodiment 2

[0024] The dry slices of the PET / attapulgite composite material with an attapulgite content of 0.2% are spun and drawn through conventional PET fiber spinning equipment and processes to obtain PET / attapulgite nanocomposite fibers. The obtained PET / attapulgite nanocomposite fiber was tested, and its breaking strength was 3.21cN / dtex, the breaking elongation was 29.60%, and the Young's modulus was 3.19×10 3 g / dtex,t 1 / 2 It is 1.17min.

Embodiment 3

[0026] The dry slices of the PET / attapulgite composite material with an attapulgite content of 0.5% are spun and drawn through conventional PET fiber spinning equipment and processes to obtain PET / attapulgite nanocomposite fibers. The obtained PET / attapulgite nanocomposite fiber was tested, and its breaking strength was 3.46cN / dtex, the breaking elongation was 28.50%, and the Young's modulus was 3.85×10 3 g / dtex,t 1 / 2 It is 1.09min.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Breaking strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com