LED lamp heat radiation method applying cross-ventilation warehouse

A technology of LED lamp and heat dissipation method, which is applied to the cooling/heating device of lighting device, lighting and heating equipment, components of lighting device, etc. weight loss effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

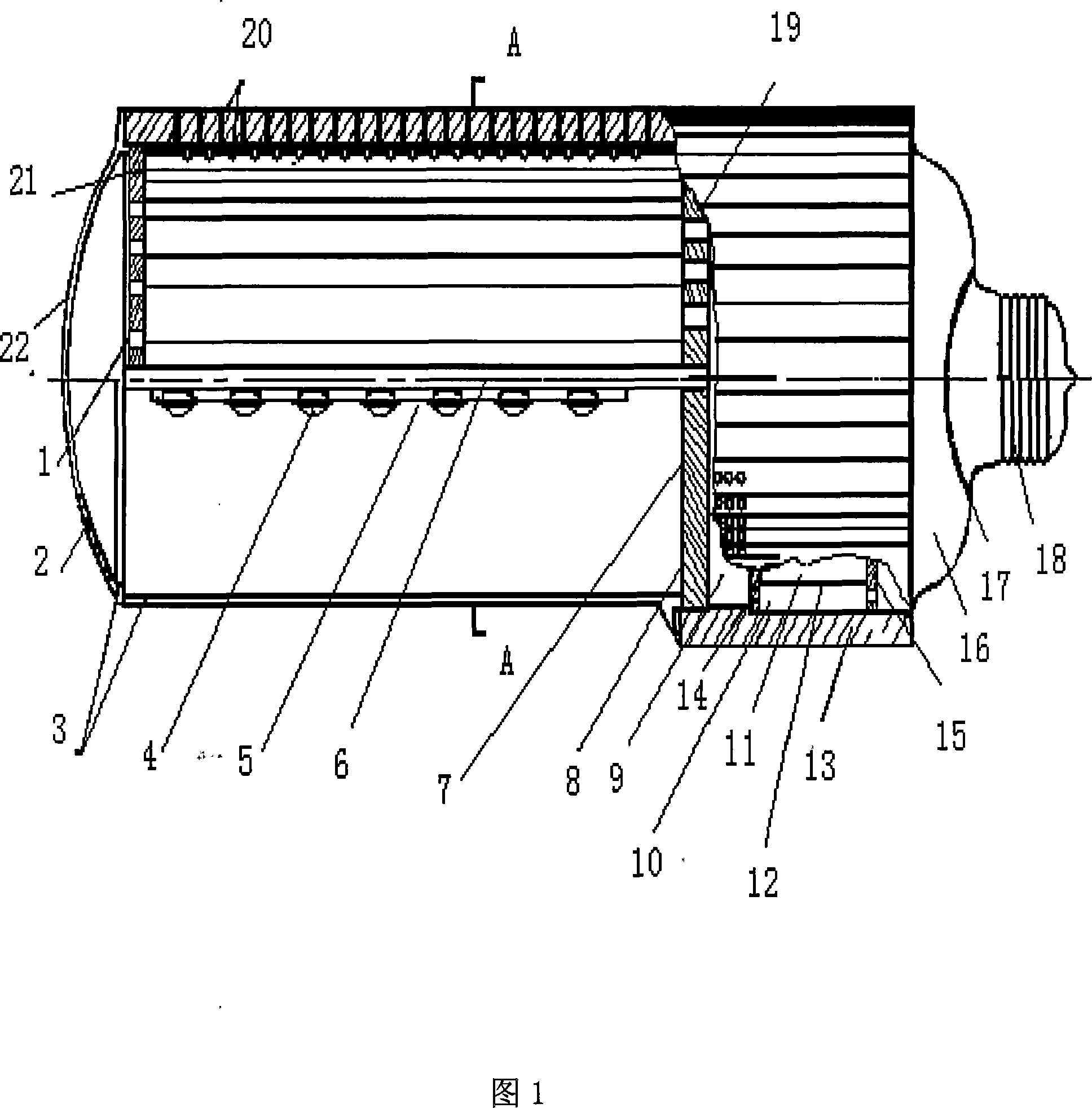

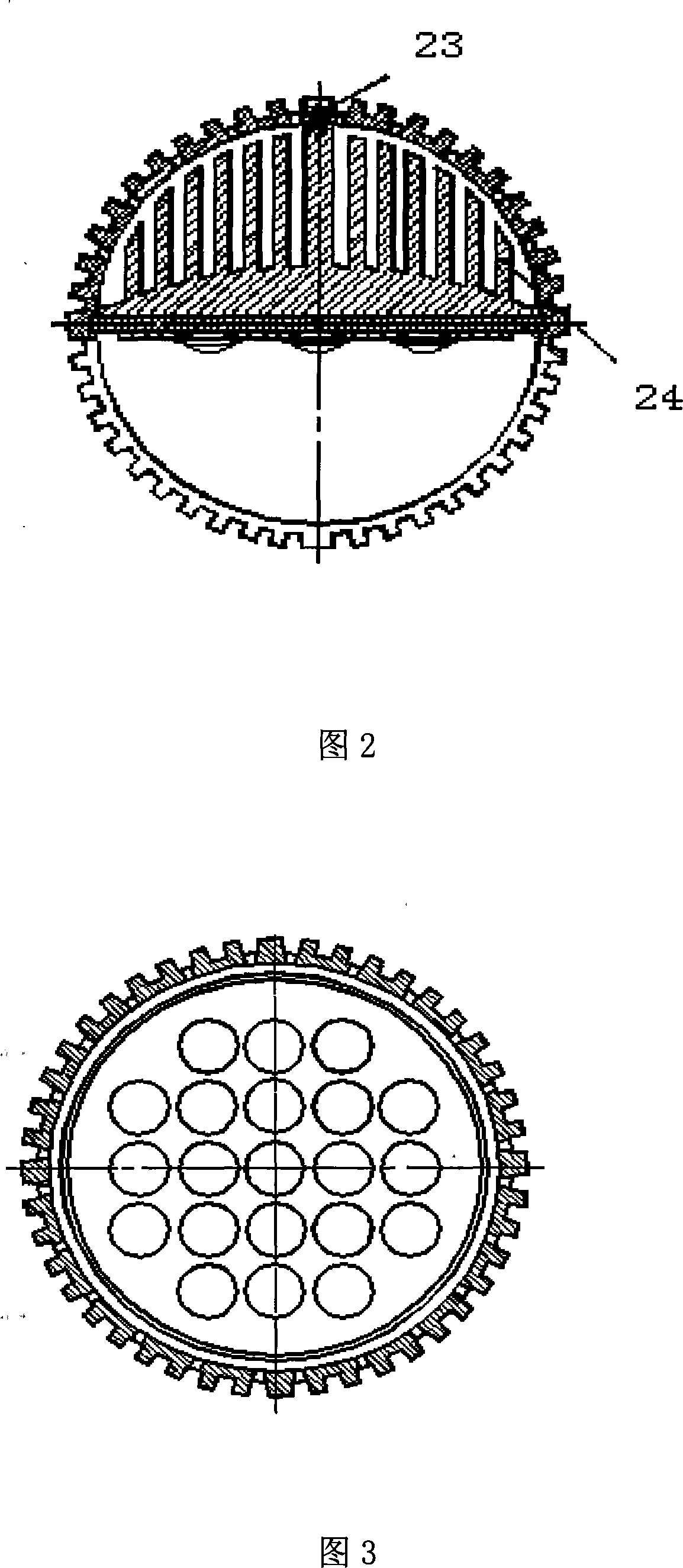

[0027] In this embodiment, a 21W horizontal LED lamp is taken as an example, as shown in Figures 1 and 2. The horizontal LED lamp with an air convection chamber described in the utility model is composed of a housing 13 with a heat dissipation function, a power supply and a constant current source. Composed of circuit board 11, LED illuminant 4, circuit board 5, aluminum heat sink, inner heat sink, lamp cover 16, lamp holder 18, and outer cover 3;

[0028]The rear half of the outer surface of the housing 13 with heat dissipation function is a concave-convex rectangular-toothed cylinder, the front half is a concave-convex rectangular-toothed half-cylinder, and the joint between the cylinder and the semi-cylinder is provided with a circular shape with the same diameter as the cylinder. The aluminum cooling plate 7, the part where the circular aluminum cooling plate 7 is connected with the semi-cylinder is provided with an air inlet 19, the cylinder is provided with an air inlet 8...

Embodiment 2

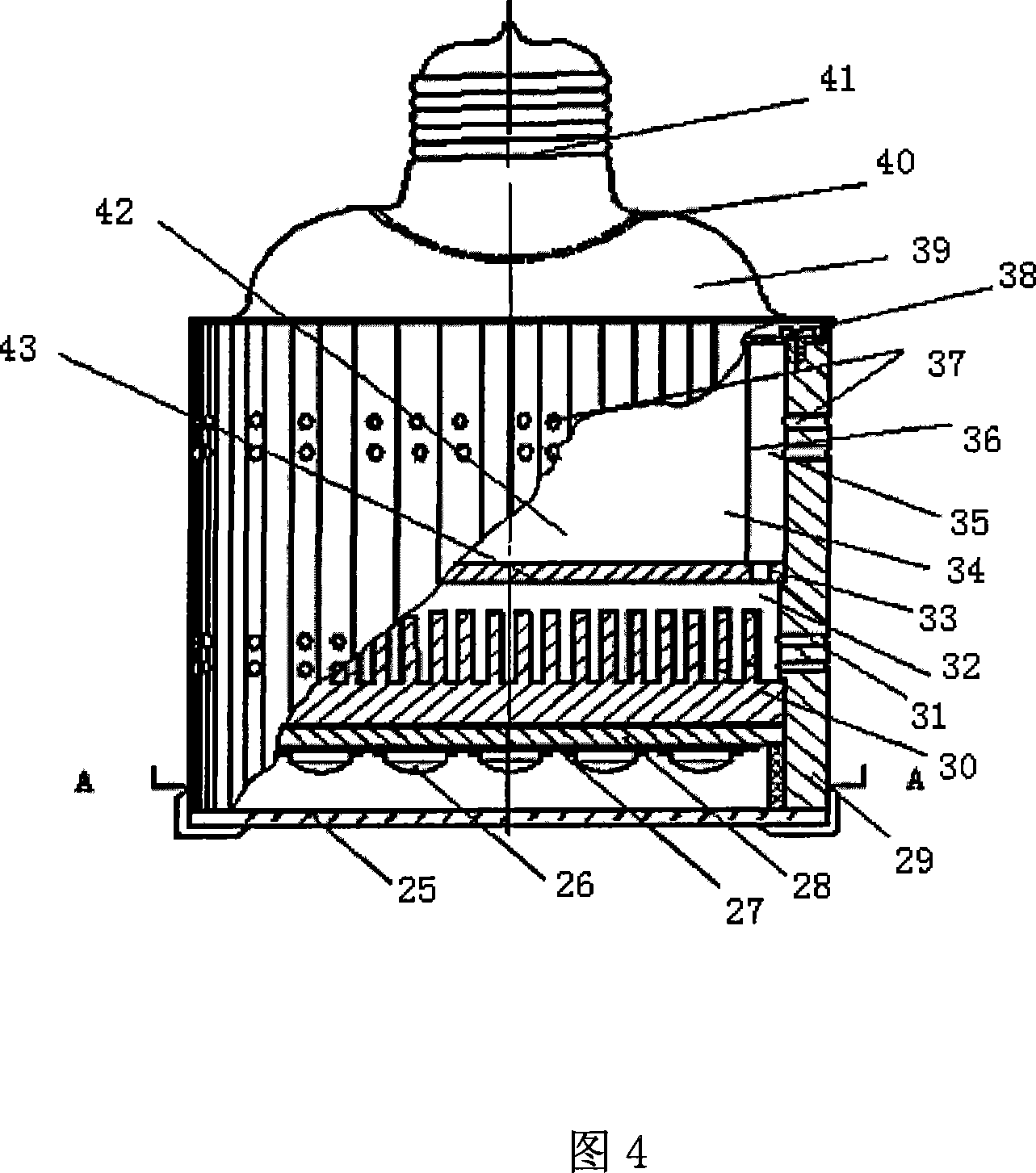

[0030] In this embodiment, a 21W straight LED lamp is taken as an example, see Figs. 3 and 4, and the structure of the straight LED lamp with an air convection chamber is described in detail.

[0031] The straight LED lamp with air convection chamber described in this embodiment is composed of a housing 29 with heat dissipation function, a circuit board 34 integrating a power supply and a constant current source, an LED illuminant 26, a circuit board 27, and three aluminum heat dissipation plates. , a cylindrical aluminum heat sink 36, and an inner heat sink 30; the housing 29 with heat dissipation function is composed of a conical, cylindrical, elliptical or rectangular pipe body with a concave-convex rectangular tooth shape on the outer surface, and openings on the walls around the lower end There are two rows of a total of 36 round holes as the air intake holes 31, and two rows of a total of 36 round holes are arranged on the wall around the upper end as the air outlet holes...

Embodiment 3

[0033] The integrated circuit board circuit structure of power supply and constant current source of the present invention is as follows:

[0034] The constant current source circuit is as follows:

[0035] Pin 1 of resistor R2 is connected to the positive pole of the LED luminous body, and connected to the positive pole of +24V power supply; pin 2 of resistor R2 is connected to the connection point of pin 2 of transistor Q2 and pin 1 of transistor Q3; pin 1 of transistor Q2 is connected to the resistor Pin 1 of R6 is connected to pin 3 of transistor Q3, pin 1 of resistor R7 is connected to the connection point of pin 1 of transistor Q2 and pin 3 of transistor Q3; pin 3 of transistor Q2, pin 2 of resistor R6, resistor R7 Pin 2 of the triode Q3 is connected to the negative pole of the LED luminous body;

[0036] The power supply circuit is as follows:

[0037] Pin 1 of capacitor C1 is respectively connected to pin 1 of eddy current coil T1 and mains +220V; pin 2 of capacitor ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com