Substrate support with a protective layer for plasma resistance

A protective layer and substrate technology, applied in the direction of ion implantation plating, application of electrostatic attraction holding device, coating, etc., can solve the problems of contaminated substrate, process defects, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

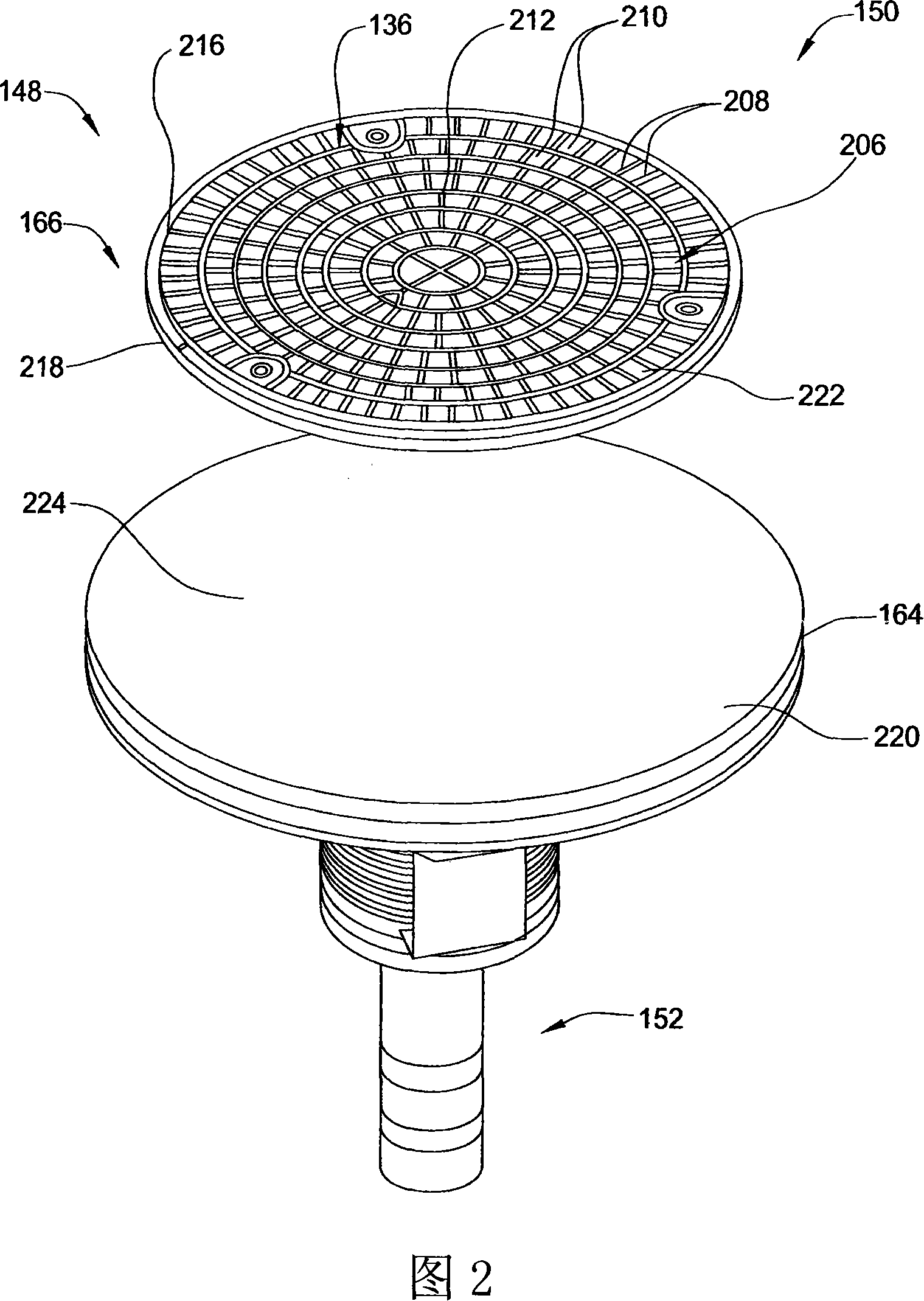

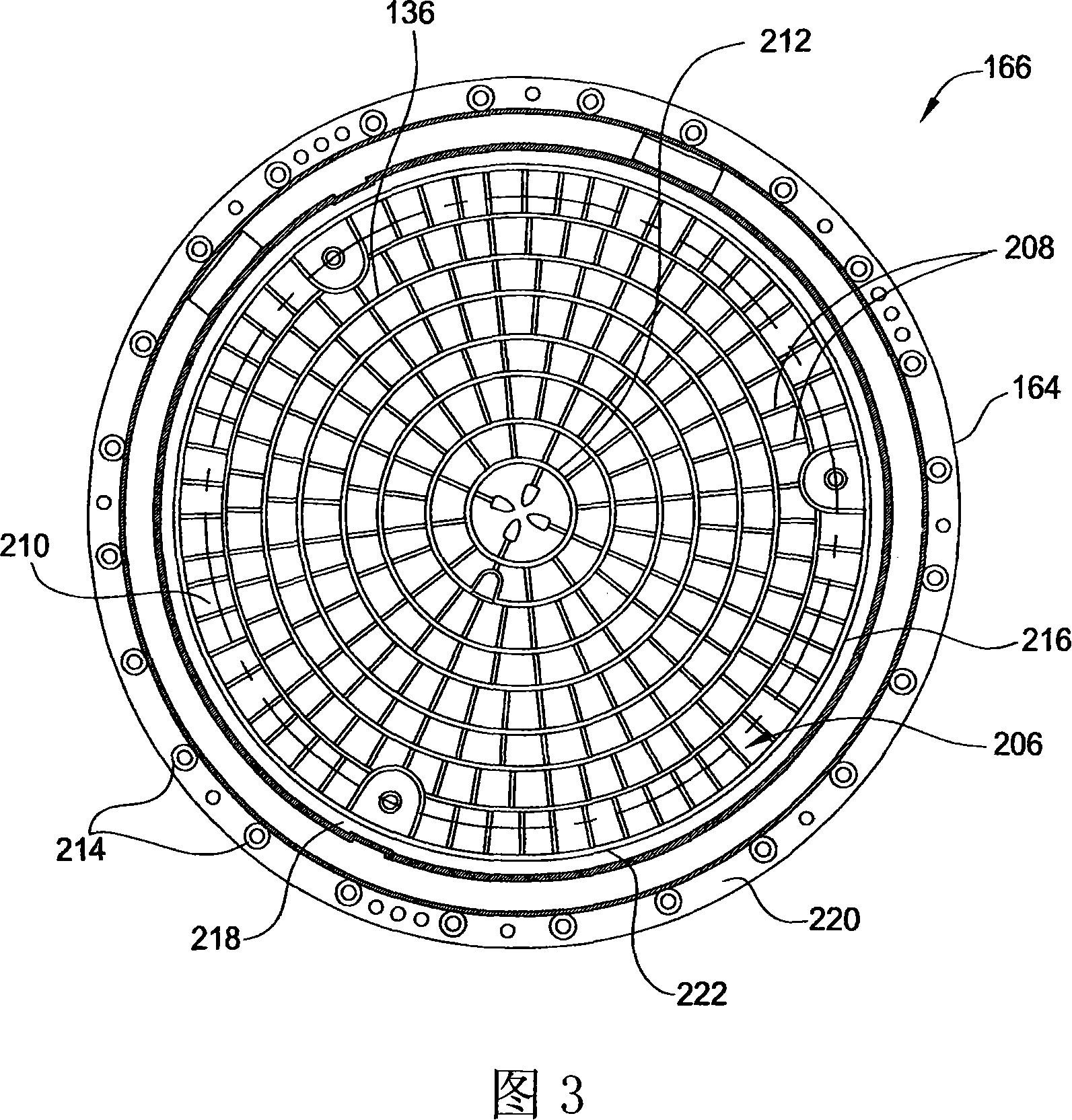

[0015] Embodiments of the present invention provide a substrate support assembly having a protective layer for enhanced plasma corrosion resistance. In one embodiment, the protective layer may be a ceramic layer including a rare earth metal. Examples of protective layers may include yttrium (Y), yttrium oxide (Y 2 o 3 ), yttrium alloys or their derivatives. The protective coating provides a corrosion-resistant surface on the substrate support assembly, thereby increasing the service life of the substrate support assembly while reducing maintenance and manufacturing costs.

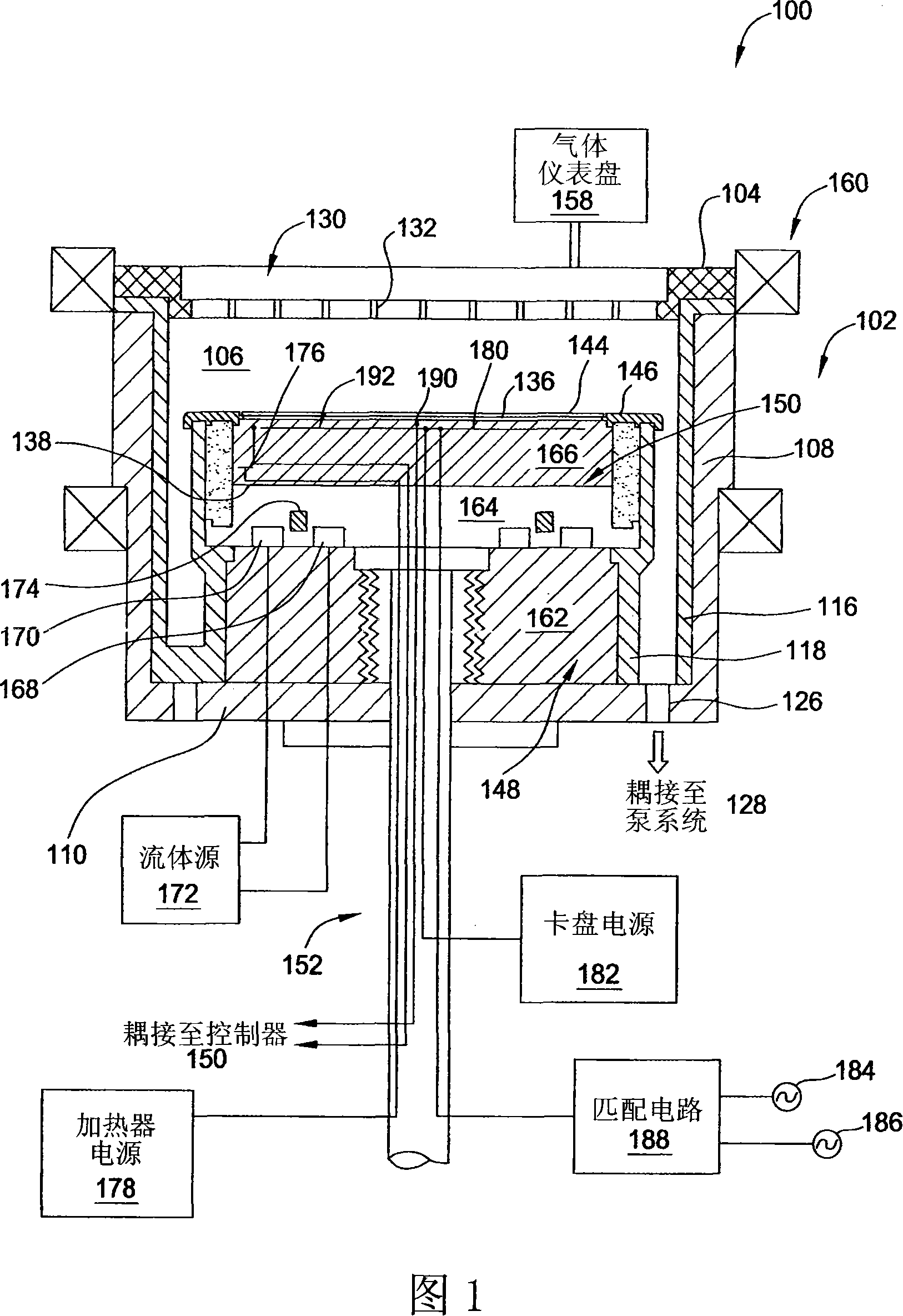

[0016] FIG. 1 shows a cross-sectional view of one embodiment of a semiconductor processing chamber having a substrate support assembly 148 disposed therein and having a protective layer 136 . While one embodiment of a substrate support assembly 148 is provided here, it is contemplated that other substrate support assemblies may be adapted to benefit from the present invention.

[0017] The processing ch...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com