Method and device for realizing double-component coat on SiC fibre surface

A fiber surface, two-component technology, applied in the field of deep processing of SiC fibers, can solve the problems of high cost and low efficiency, achieve strict thickness control, stable technical performance, and reduce production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

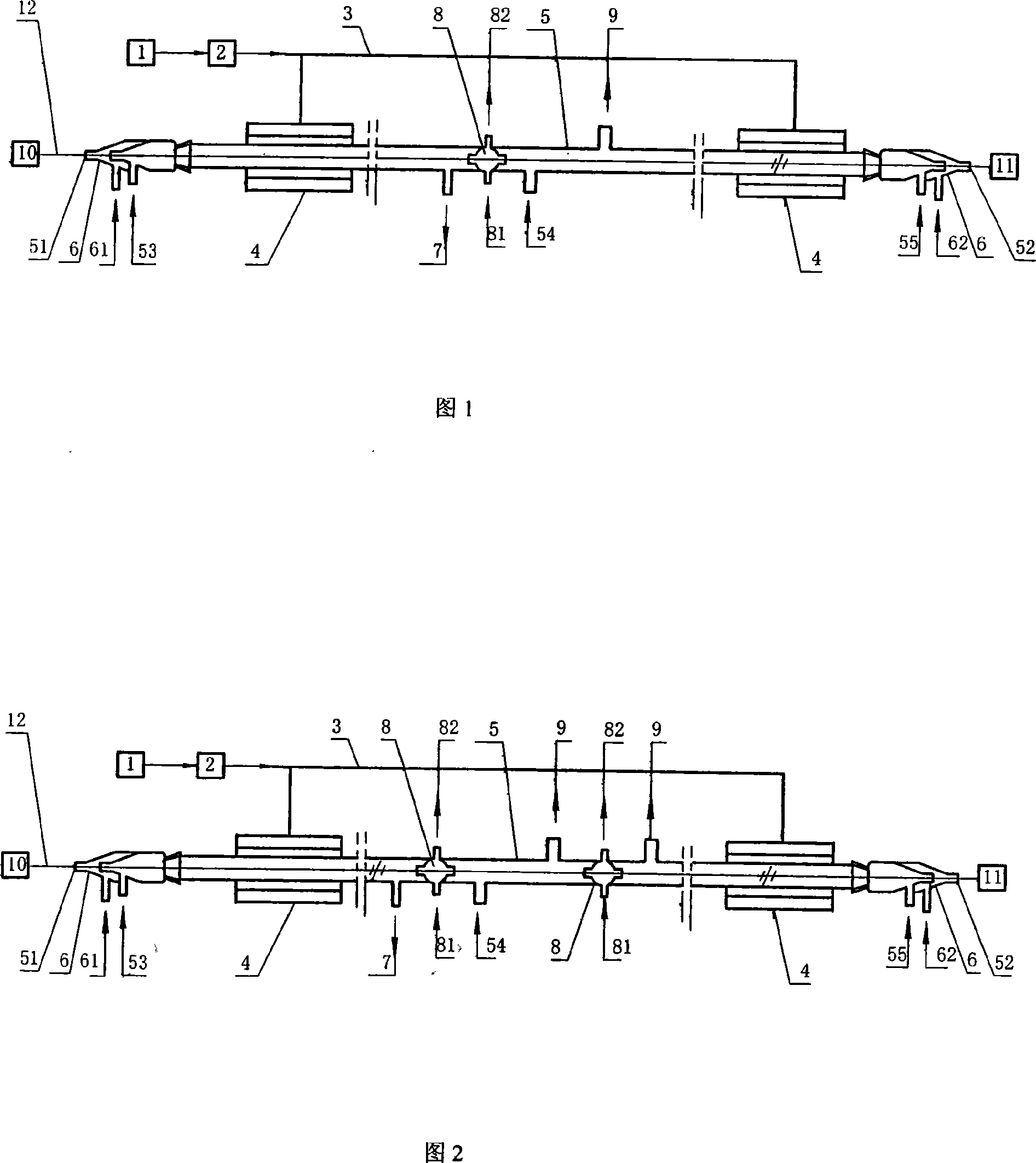

[0019] It can be clearly seen with the help of the accompanying drawings that the method designed by the present invention to realize the two-component coating on the surface of SiC fibers is to heat the moving tungsten wire 12 by means of a radio frequency focused heating device, and utilizes vapor deposition The process of generating SiC fibers by method, the key steps are:

[0020] (1) The structure of the quartz tube thermal reactor in the radio frequency focused heating device is modified so that the heating reaction zone has three independent vapor deposition zones that are sealed and isolated by the argon gas filled in the argon gas seal. ,

[0021] (2) by means of the tungsten wire 12 heated by the traction and focusing radio frequency electric field of the wire feeding and receiving mechanism (10, 11) passing through three vapor deposition areas successively,

[0022] (3) Zone I is the SiC fiber layer forming zone. By introducing the mixed gas of chlorosilane and hig...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com