Method and device for making fluid bed to produce super high-temperature fume

A fluidized-bed gasifier and fluidized-bed technology are applied in the directions of fluidized-bed combustion equipment, combustion methods, and fuels burned in a molten state, which can solve problems such as limiting the scope of application, and achieve expansion of the scope of application, pressure-fire start-up, etc. Fast, easy-to-run effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

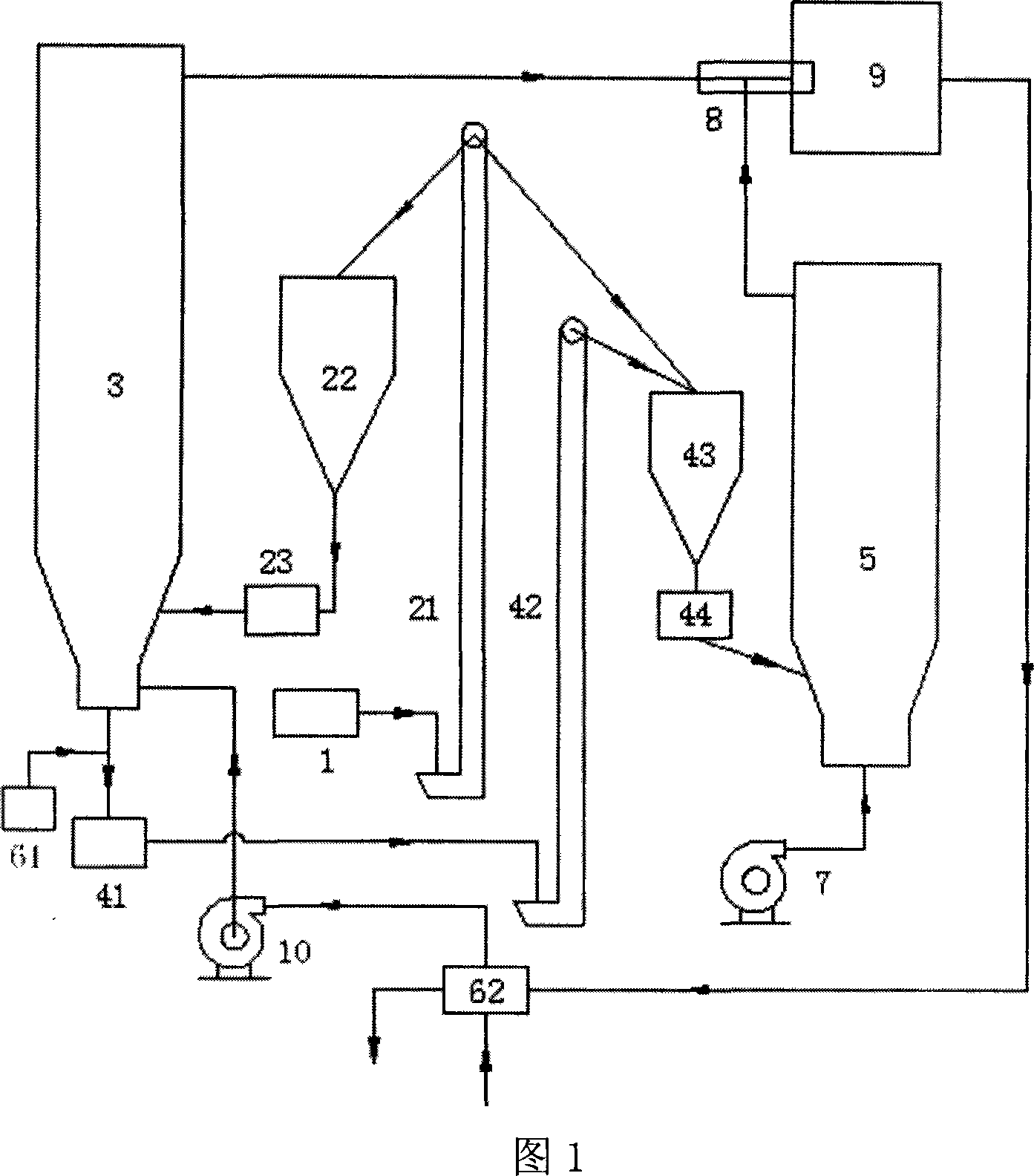

[0019] The working process and specific implementation of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0020] The processing procedure of the inventive method is:

[0021] (1) Send the coal crushed by the crusher into the fluidized bed gasification furnace, pass it into the gasification medium, and perform partial gasification to generate high-temperature gas; the gasification medium can only use preheated air and discharge it from the burnout chamber The high-temperature exhaust gas is used to preheat the cold air; the preheated air and water vapor can also be used at the same time; the air can also be directly used without preheating.

[0022] (2) The gasified semi-coke discharged from the gasifier is transported to the fluidized bed flue gas generator, and the flue gas generator passes air with an excess coefficient greater than 1.5 to burn the semi-coke and generate a large amount of high-temperature flue gas.

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com