Artemisinin derivatives freeze-dried preparation and preparation method

A technology for freeze-dried preparations and derivatives, which is applied in the field of freeze-dried preparations and preparations of artemisinin derivatives, which can solve problems such as microbial contamination and organic solvent residues, and achieve the effects of short production cycle, fast dissolution speed and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

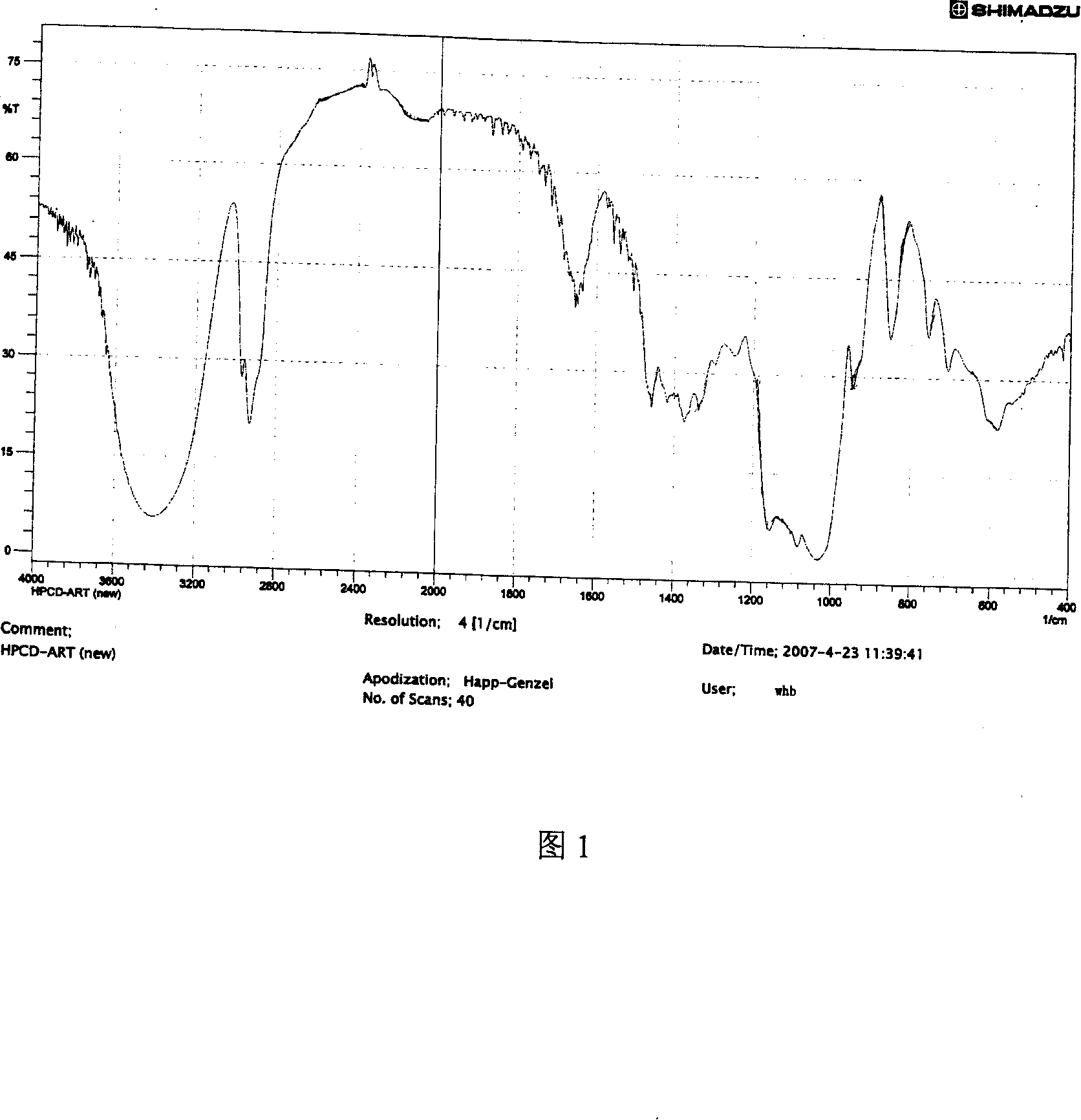

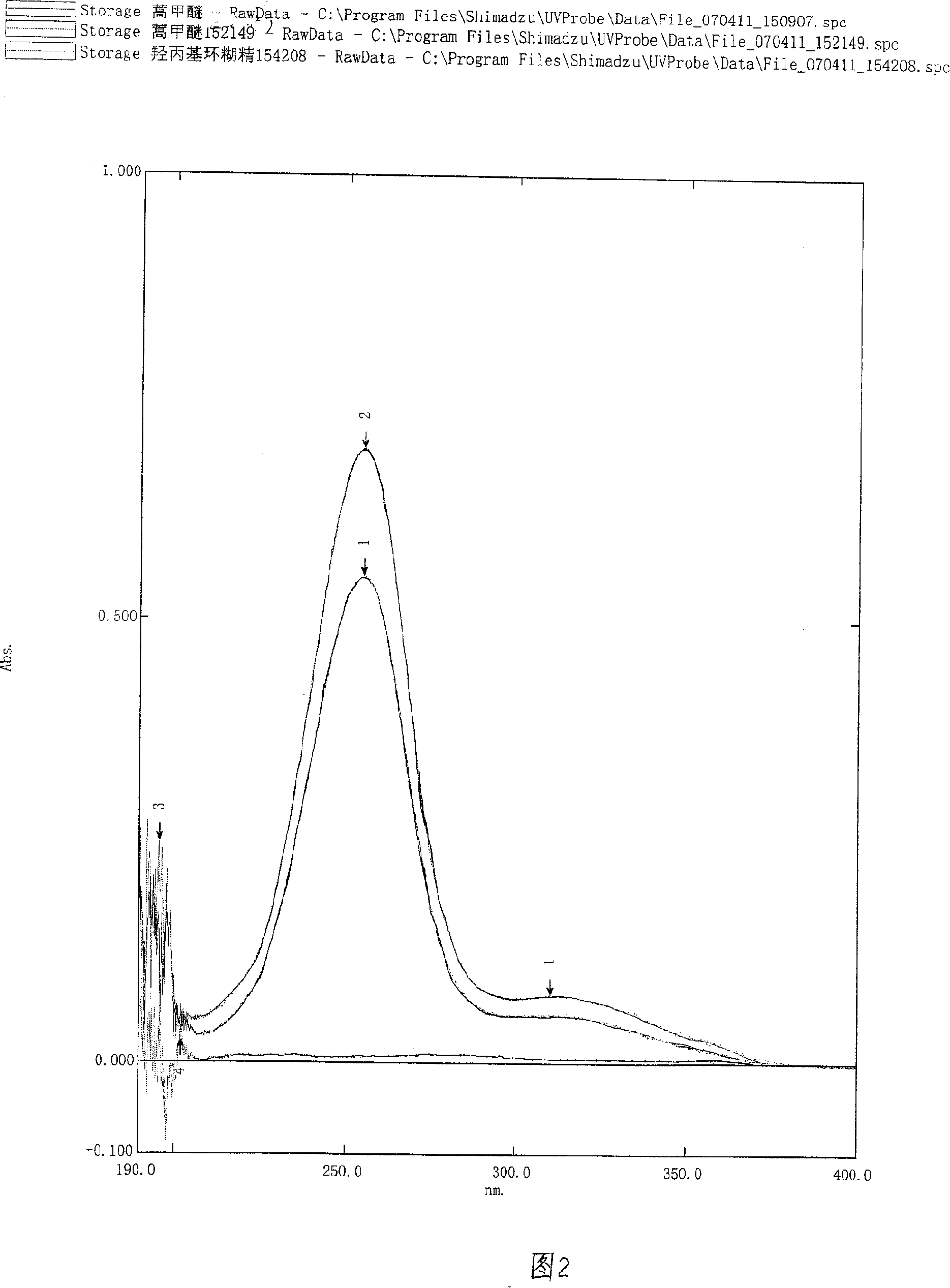

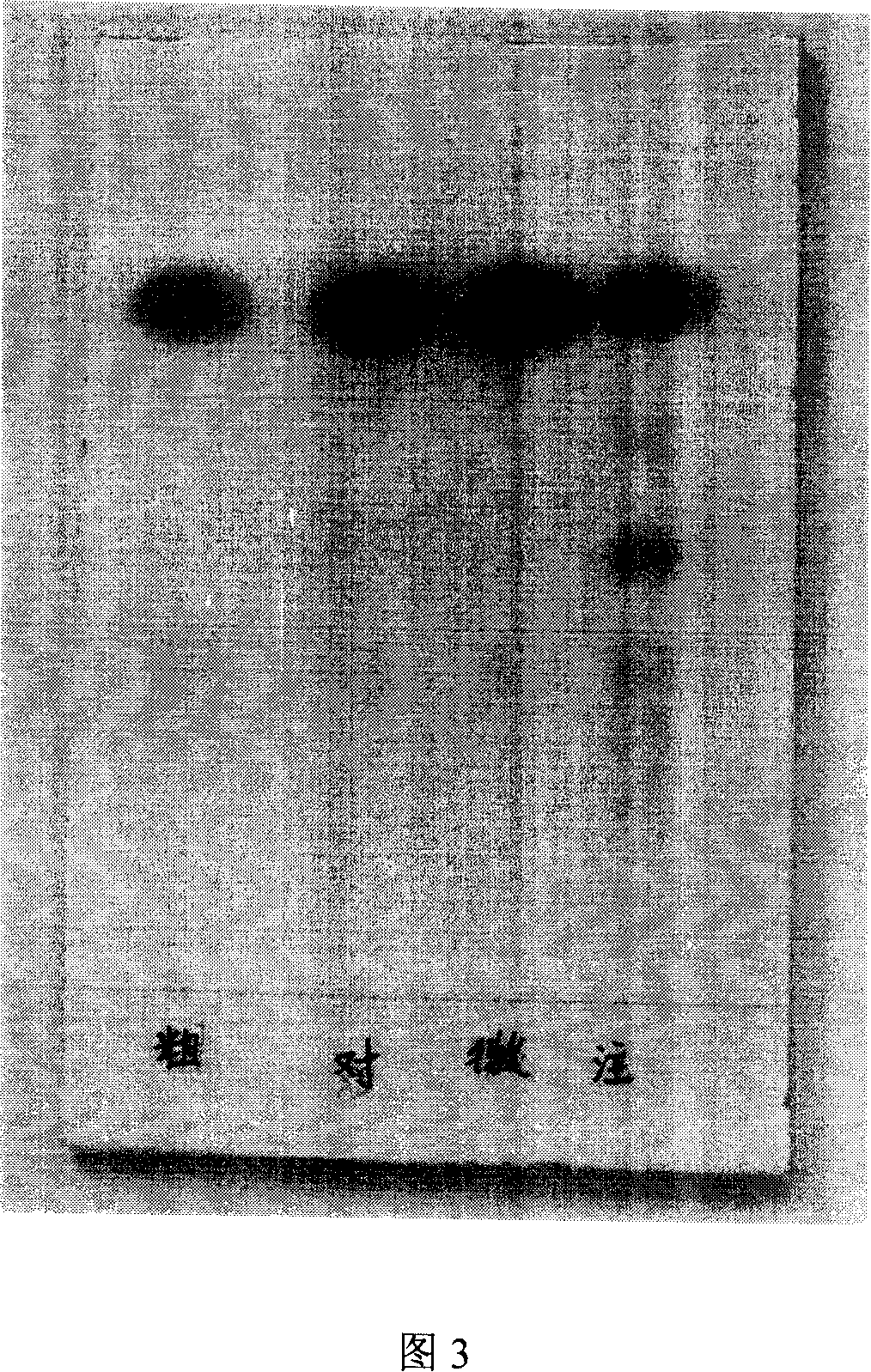

Method used

Image

Examples

Embodiment 1

[0028] formula:

[0029] Artemether (conventional refined powder, particle size greater than 315μm) 60g

[0030] Hydroxypropyl-β-cyclodextrin 2350g

[0031]

[0032] Made 1000 pieces

[0033] Weigh the hydroxypropyl-β-cyclodextrin of the prescribed amount, first take 1600g and dissolve it in 4000ml water for injection to make a concentration of 40%, heat it to 70°C-90°C, add the prescribed amount of artemether (particle size greater than 315 μm), stir, then add the remaining hydroxypropyl-β-cyclodextrin, stir to dissolve, add water for injection to 5000ml, fill, freeze-dry to obtain the finished product.

Embodiment 2

[0035] formula:

[0036] Artemether (fine powder 1.0μm~10μm) 60g

[0037] Hydroxypropyl-β-cyclodextrin 2200g

[0038]

[0039] Made 1000 pieces

[0040] The artemether is pulverized by a low-temperature pulverizer (0° C. to 10° C.) to obtain artemether with a particle size of 1.0 μm to 10 μm. Separately weigh the prescribed amount of hydroxypropyl-β-cyclodextrin, firstly take 1800g and dissolve it in 4000ml water for injection to make a concentration of 45%, heat it to 50°C-60°C, add the prescribed amount of artemether, stir, Then add the remaining hydroxypropyl-β-cyclodextrin, stir to dissolve, add water for injection to 5000ml, fill and freeze-dry to obtain the finished product.

Embodiment 3

[0042] formula:

[0043] Artemether (fine powder 1.0μm~20μm) 80g

[0044] Sulfobutyl ether-β-cyclodextrin 440

[0045] Methyl-β-cyclodextrin 2000

[0046]

[0047] Made 1000 pieces

[0048] The artemether is pulverized by a low-temperature pulverizer (0° C. to 10° C.) to obtain artemether with a particle size of 1.0 μm to 20 μm. In addition, take the sulfobutyl ether-β-cyclodextrin and methyl-β-cyclodextrin of prescription quantity, first get the methyl-β-cyclodextrin of 1200g and be dissolved in 4000ml water, make the concentration of 30%, add Warm to 50 ℃ ~ 60 ℃, add the prescribed amount of artemether, stir, then add the remaining methyl-β-cyclodextrin and sulfobutyl ether-β-cyclodextrin, stir to dissolve, add water for injection to 5000ml, filled and freeze-dried to get the finished product.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com