Combination device for adsorption desulfurization and biological reactivation adsorption agent, and operating method thereof

An adsorption desulfurization and adsorbent technology, applied in the biological field, can solve the problems of difficult separation of adsorbents and desulfurization microorganisms, adsorbent consumption, large operating costs, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] Use Nocardia parvum R-9 to regenerate the Cu(I) / Y adsorbent, the Cu(I) / Y adsorbent adopts the prior art, with NaY molecular sieve as the adsorbent carrier, Cu(I) / Y 2+ Ion exchange for 48 hours, dry at 100°C for 24 hours, and then use H 2 , N 2 Under the protection of mixed gas (volume ratio 10:90), it is obtained by reduction at 220°C.

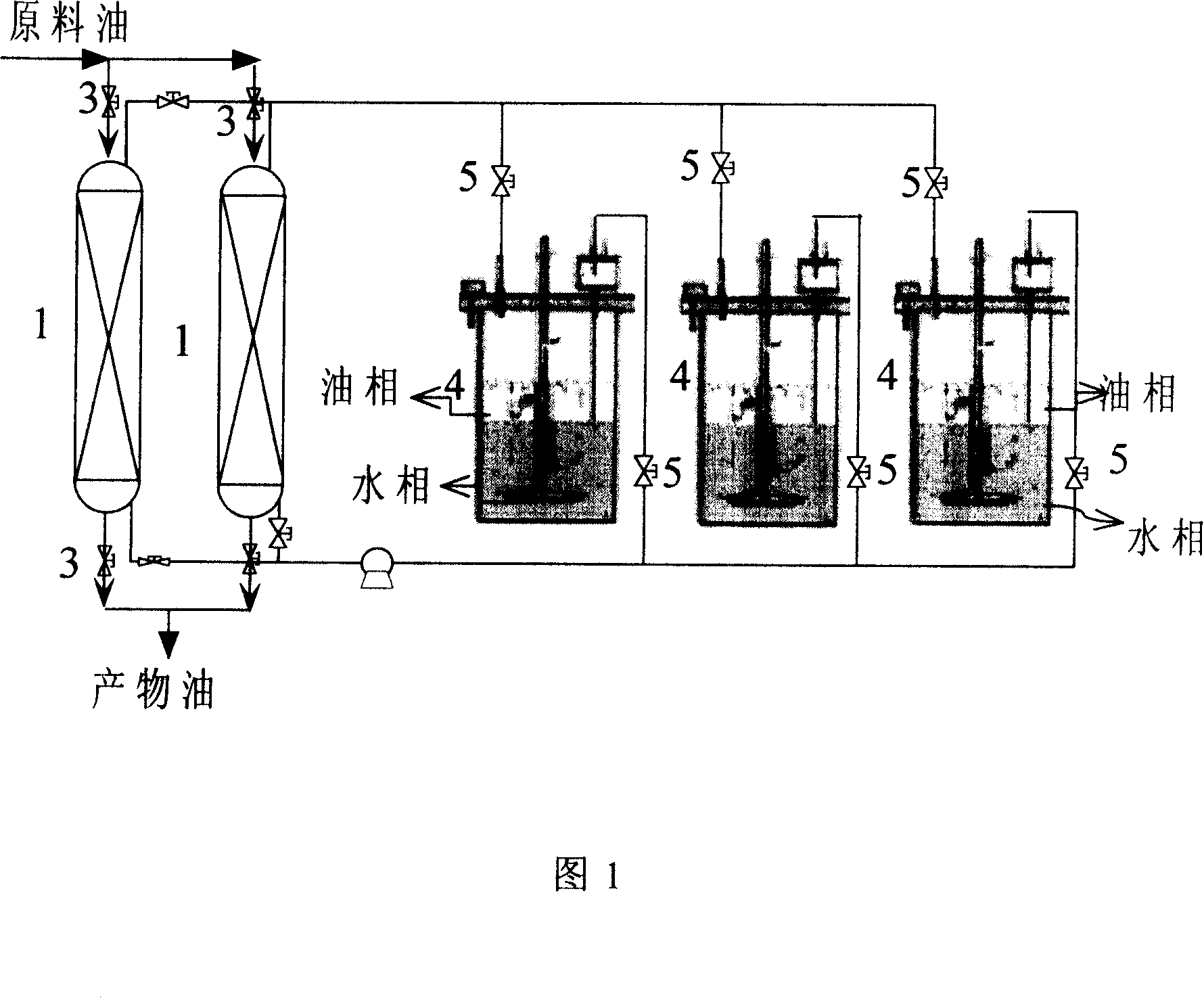

[0035] See Figure 1. The tops of the two adsorptive desulfurization fixed-bed reactors 1 are respectively provided with raw material oil inlets, the upper part is provided with regeneration circulating fluid outlets, and the bottom is provided with regeneration circulating fluid inlets and product oil outlets;

[0036] The tops of the three biological desulfurization reactors 4 with stirring devices are respectively provided with the inlet of the regenerated circulating fluid, the outlet of the regenerated circulating fluid, the air inlet and the discharge port, and a biological desulfurization reaction device is installed at the disc...

Embodiment 2

[0046] Using the device and operation method of Example 1, Rhodococcus erythropolis LSSE8-1 was used to regenerate the loaded NiO / USY adsorbent.

[0047] The loaded NiO / USY adsorbent that has adsorbed sulfur is desorbed and regenerated using the specific biological desulfurization catalyst Rhodococcus erythroflates LSSE8-1. The concentration of microbial cells in the water phase is 25g / L, and the water phase is pH=6.0~ 7.0 phosphate buffer solution, add gasoline as the oil phase, the volume ratio of the oil phase to the water phase is 0.3, fully stir and emulsify in the desulfurization reactor, and the ratio of the loaded NiO / USY adsorbent that has adsorbed sulfur to the water phase is 5.0g / L, passed into a fixed bed saturated with adsorbed sulfides. After drying at 120°C and calcining at 500°C, the regenerated desulfurization adsorbent NiO / USY was obtained.

[0048] The supported NiO / USY adsorbent is obtained by using USY molecular sieve as the adsorbent carrier, impregnati...

Embodiment 3

[0051] Using the device and operation method of Example 1, Pseudomonas delbrueckii R-8 was used to regenerate the loaded ZnO-NiO / Y adsorbent.

[0052] The loaded ZnO-NiO / Y adsorbent that has adsorbed sulfur is desorbed and regenerated using the specific biological desulfurization catalyst Pseudomonas delbrueckii R-8. The concentration of microbial cells in the water phase is 35g / L, and the water phase is Physiological saline, add dimethyl sulfoxide as the oil phase, the volume ratio of the oil phase to the water phase is 0.3, fully stir and emulsify in the desulfurization reactor, and the ratio of the loaded ZnO-NiO / Y adsorbent that has adsorbed sulfur to the water phase is 5.0 g / L, passed into the fixed bed saturated with adsorbed sulfide. After drying at 100°C and calcining at 450°C, the regenerated desulfurization adsorbent ZnO-NiO / Y is obtained.

[0053] The supported ZnO-NiO / Y adsorbent is obtained by using USY molecular sieve as the adsorbent carrier, impregnating NiO a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com