Alcohol crossed circle manufacturing technique with potatoes as the main materials

A production process, a double-circle technology, applied in the direction of biofuels, fermentation, etc., can solve the problems of difficult and thorough wastewater treatment, the use of industrial production scale, limited cycle batches, etc., to reduce floor space and fixed asset investment, good Economic benefits, the effect of reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

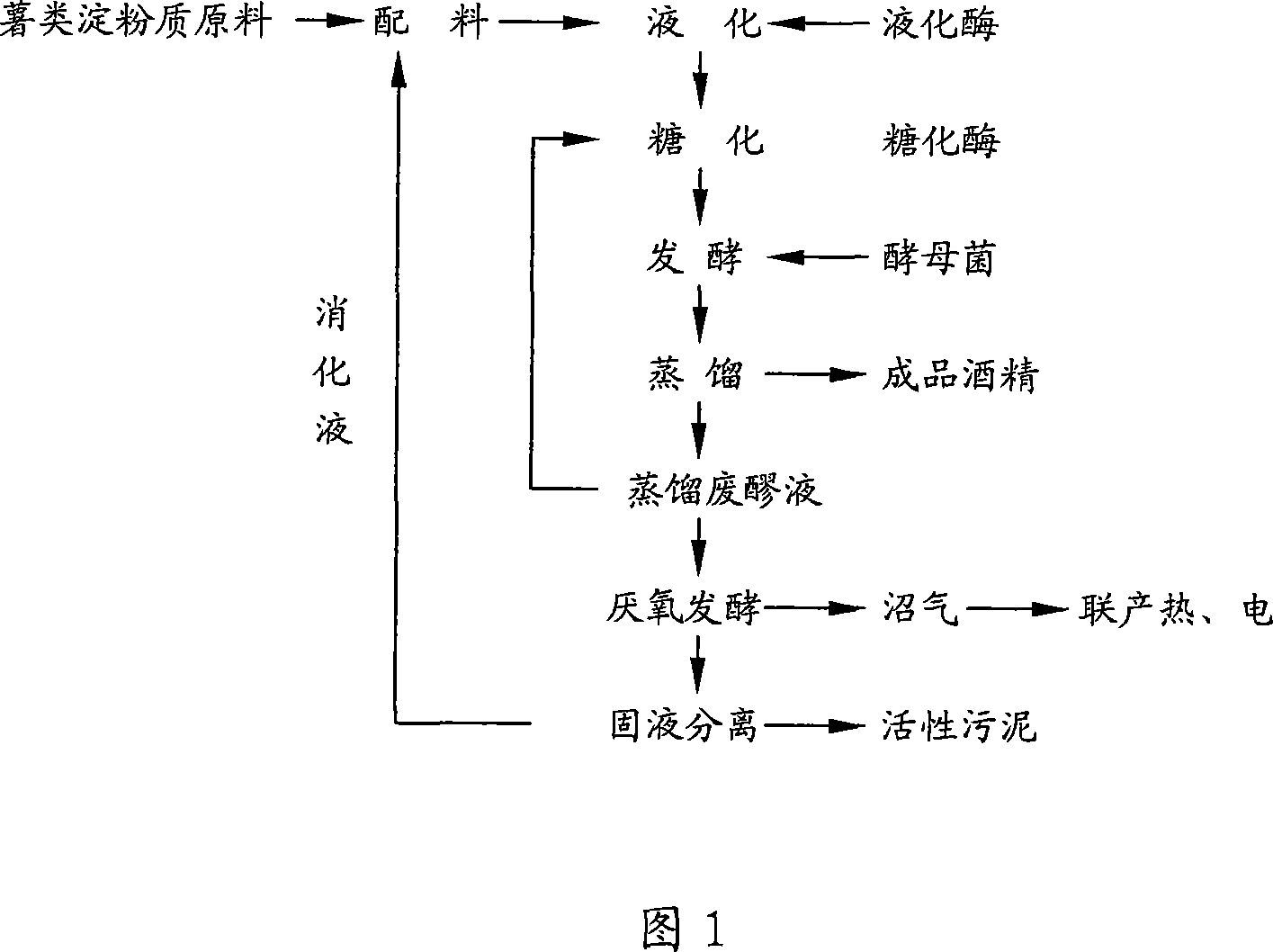

[0024] The present invention uses potatoes as the main raw material for the alcohol double ring production process to adopt the following process steps:

[0025] Take 100g of sweet potato powder, add 200ml of the previous batch of anaerobic fermentation digestion liquid, add 0.07ml of high-temperature-resistant α-amylase, stir evenly and heat, keep warm at 95°C for 60 minutes to liquefy; quickly cool down to 58°C, add the previous batch of distillation waste mash 100ml, add 0.15ml of glucoamylase (common commercial glucoamylase) after mixing, keep saccharification at 62°C for 0.5hr, cool down to 30°C after saccharification, add 10% expanded alcoholic yeast, and ferment at constant temperature for 64hr; The volume of the mature fermented liquid is 343ml, and the alcohol concentration is 9.2% (v / v); 32ml (95.2% v / v) of finished alcohol is obtained through distillation and 310ml of distilled waste mash is obtained. Take out 100ml of waste mash as water for the next batch of sacch...

Embodiment 2

[0027] The present invention uses potatoes as the main raw material for the alcohol double ring production process to adopt the following process steps:

[0028] Take 2000g of cassava flour, add 4000ml of the previous batch of anaerobic fermentation digestion liquid, add 1.2ml of high-temperature-resistant α-amylase, stir evenly and heat, keep warm at 95°C for 50 minutes to liquefy; quickly cool down to 62°C, add the previous batch of distillation waste mash 2000ml, add 2.4ml of glucoamylase (common commercial glucoamylase), keep saccharification at 62°C for 0.5hr, cool down to 30°C after saccharification, add 8% expanded alcoholic yeast to ferment at constant temperature, and ferment for 60hr; after fermentation, mature fermentation The liquid volume is 6850ml, and the alcohol concentration is 11.9% (v / v); 740ml (96% v / v) of finished alcohol is obtained through distillation, and 6200ml of distilled waste mash is obtained. Set aside 2000ml of waste mash as water for the next b...

Embodiment 3

[0030] The present invention uses potatoes as the main raw material for the alcohol double ring production process and adopts the following process steps:

[0031] Take 9000kg of cassava flour and add 24m of the last batch of digestive juice 3 , add 3.2 liters of high-temperature-resistant α-amylase, stir evenly and heat, keep warm at 95°C for 60 minutes to liquefy; quickly cool down to 65°C, add 4m of the previous batch of distilled waste mash 3 , add 9 liters of glucoamylase (common commercial glucoamylase), keep saccharification at 62°C for 0.45hr, cool down to 28°C after saccharification, insert 8% expanded alcoholic yeast for fermentation, and ferment for 66hr; after fermentation, the volume of mature fermentation liquid is 35.6m 3 , the alcohol concentration is 10.3% (v / v); the finished alcohol 3040L (96% v / v) is obtained by distillation, and the distillation waste mash is 32.6m 3 , through the sedimentation tank to separate the mud and sand, leaving 4m 3 The waste ma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com