Soft tissue stab-resistant material and soft tissue compound structure

A composite structure, anti-stab technology, applied in textiles, papermaking, fiber processing, etc., can solve problems such as difficult human body protection, poor energy absorption effect, unfavorable protection personnel, etc., to achieve excellent anti-stab performance, light weight, excellent anti-stab performance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

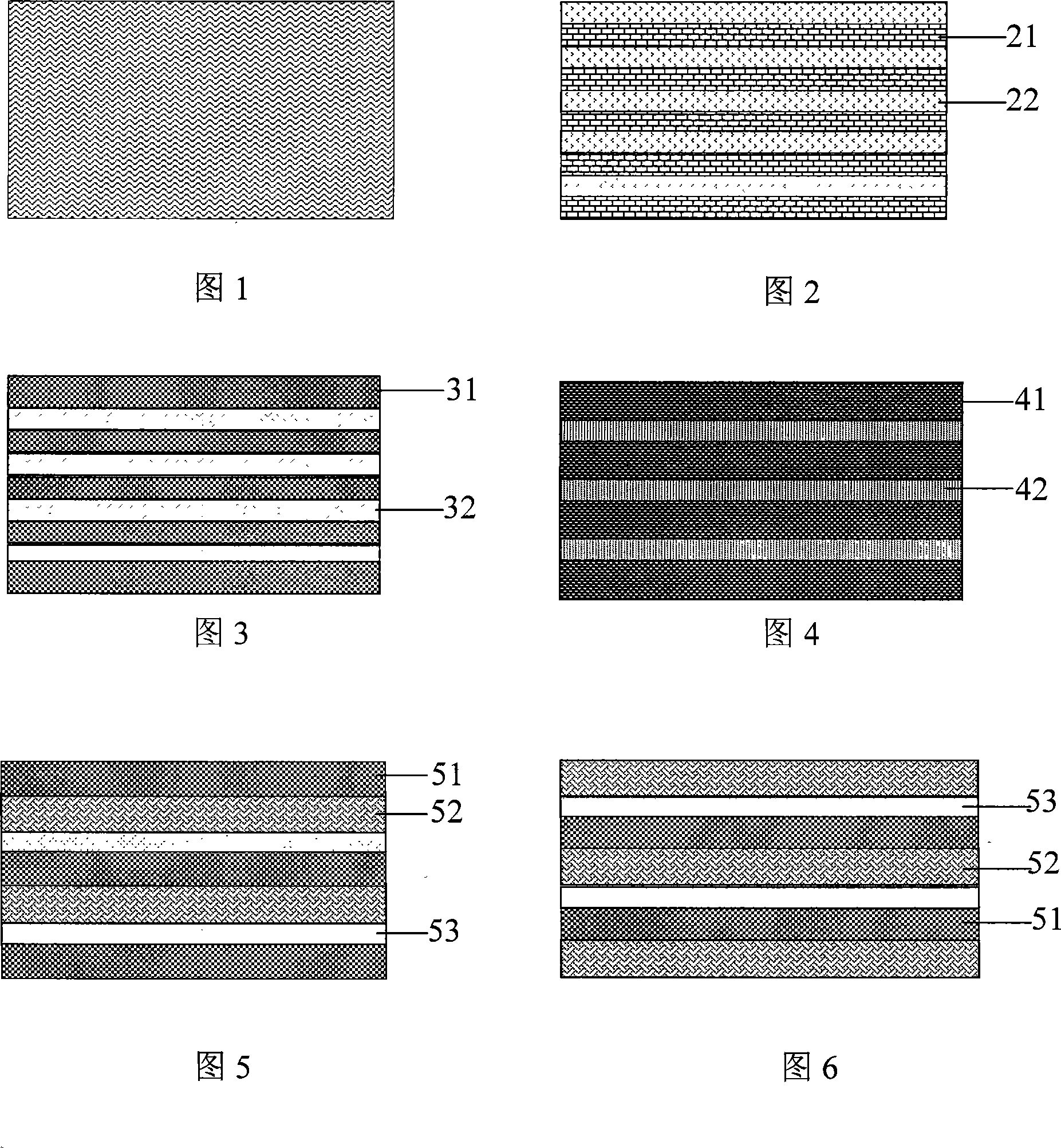

[0022] A composite soft anti-stab material is prepared by using satin cloth woven with polyphenylene benzobisoxazole (PBO) fibers and 60 wt% (weight ratio) superfine silica shear thickening solution as raw materials. Firstly, dilute the nano silicon dioxide solution with ethanol as a diluent, and the approximate dilution ratio of ethanol:shear thickening liquid is 5:1 to 0.1:1. Then impregnate the PBO fiber cloth in the diluent, and at the same time carry out ultrasonic strengthening treatment on the impregnated system. Methods Ethanol was removed from the compounded material. This liquid composite material is used in a multi-layer stacking manner, as shown in Figure 1, to prepare a highly efficient stab-resistant composite structure, which is applied to different stab-resistant products. According to the standard GA68-2003 of the Ministry of Public Security, the puncture test of the material and structure was carried out, and it was found that compared with the PBO fiber clo...

Embodiment 2

[0024] Aramid fiber (Kevlar fiber) plain cloth and nano-titanium oxide shear thickening liquid with a concentration of 10wt% were used as raw materials to prepare soft stab-resistant materials. Use ethanol as the diluent to dilute the nano-shear thickening liquid, then impregnate the aramid fiber cloth in it, and at the same time perform high-frequency vibration treatment on the impregnated system, the vibration frequency is 1000-3000 Hz, and then vacuum desolventize the Ethanol is excluded to prepare aramid cloth liquid composite soft stab-proof material. Two kinds of materials, aramid cloth liquid composite anti-stab material 21 and aramid cloth 22, are used in a multi-layer superimposed manner, and the structures are respectively multi-layer aramid cloth and multi-layer liquid composite material from outside to inside, as shown in Fig. 2 Shown, compounded to prepare high-performance soft anti-stab products. According to the standard GA68-2003 of the Ministry of Public Secu...

Embodiment 3

[0026] The soft anti-stab material is prepared by using ultra-high molecular weight polyethylene fiber non-woven fabric and 40wt% nano-silica shear thickening liquid as raw materials. First, the ultra-high molecular weight polyethylene non-woven fabric is laid flat, and then the shear thickening liquid is coated on the non-woven fabric, and compacted to form an interlayer composite soft stab-proof material. Utilize this soft anti-stab material to form a multi-layered anti-stab composite structure, as shown in Figure 3, ultra-high molecular weight polyethylene non-woven fabric 31, shear thickening liquid interlayer composite anti-stab material 32, prepared Stab-resistant composite construction. According to the standard GA68-2003 of the Ministry of Public Security, the puncture test of the material and structure was carried out, and it was found that the liquid composite soft stab-proof material and the stab-proof composite structure have the characteristics of light weight, so...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com