Flash memory device and manufacturing method thereof

A device and control gate technology, applied in the field of flash memory devices and its manufacturing, can solve the problems of low programming and erasing operation speed, difficulty in obtaining wide storage window, SONOS limitations, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

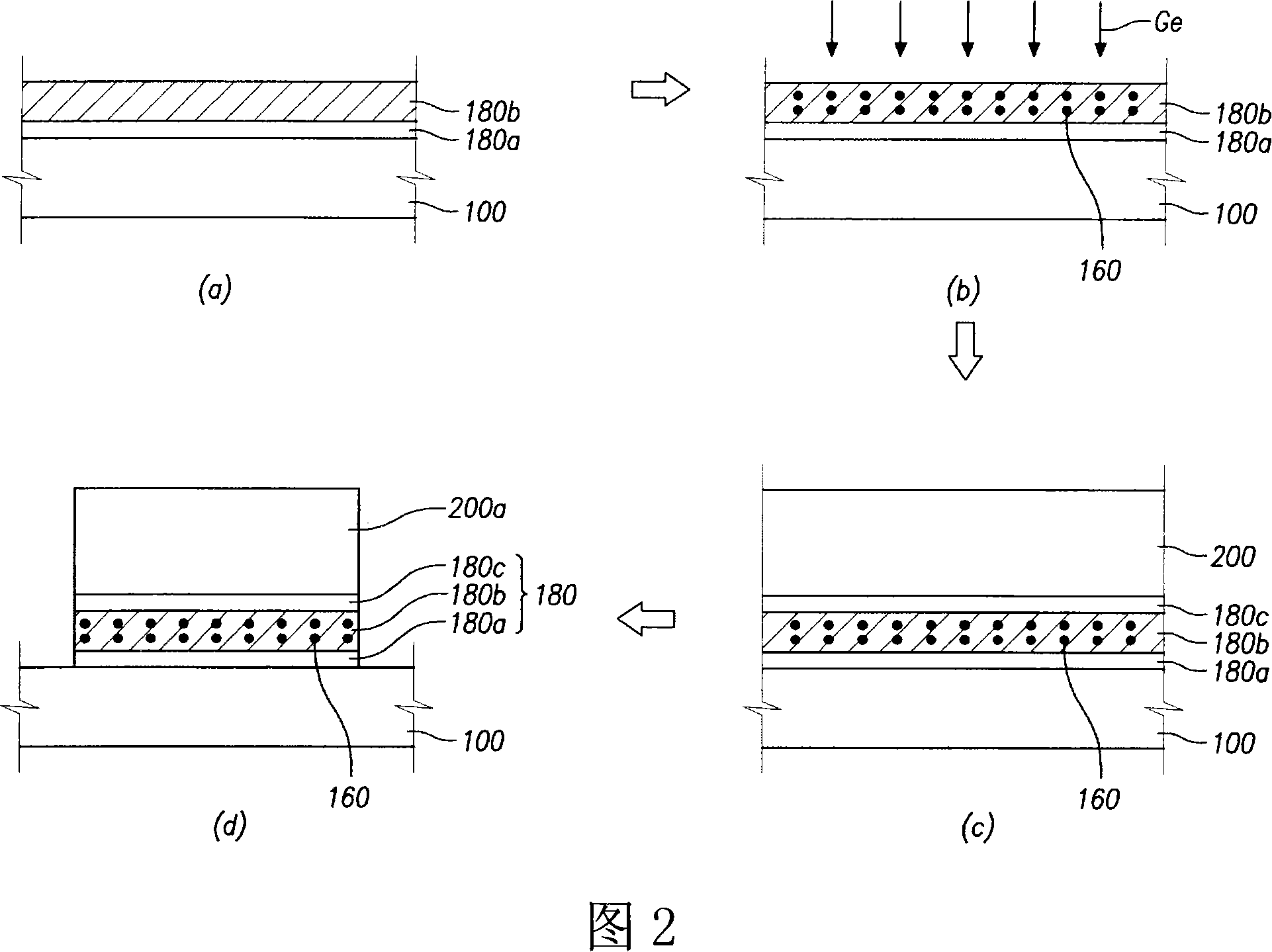

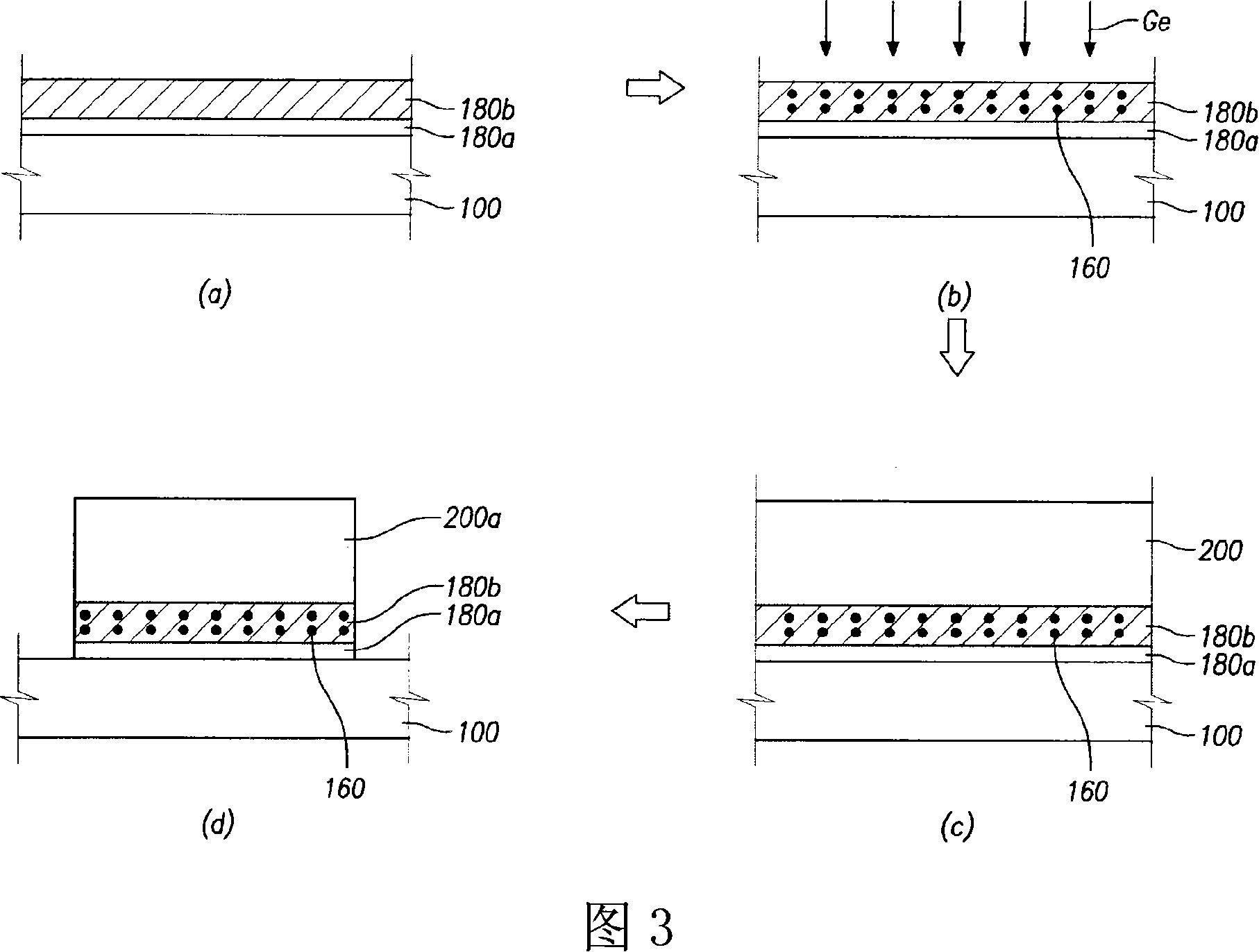

[0016] FIG. 2 is a cross-sectional view illustrating a method of fabricating a flash memory device according to embodiments described herein.

[0017] First, as shown in (a) of FIG. 2, a silicon oxide film is formed on a silicon semiconductor substrate 100 having a thickness between about 15 Ȧ and about 40 Ȧ, wherein the silicon oxide film is used as a tunnel oxide film 180a. In this case, the silicon oxide film 180a may be a thermally oxidized film formed by oxidizing the substrate 100, or may be deposited by chemical vapor deposition (CVD) or physical vapor deposition (PVD). After forming the tunnel oxide film 180a, a silicon nitride film 180b is formed by CVD or PVD, wherein the silicon nitride film 180b is formed to a thickness between about 50 Ȧ and about 250 Ȧ. The silicon nitride film 180b functions as a charge storage layer in which electrons or holes are trapped or de-trapped in the operation of the flash memory device. Generally, the tunnel oxide film 180a, the sili...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com