Method for preparing TS-1 molecular sieve

A molecular sieve, TS-1 technology, applied in molecular sieve compounds, chemical instruments and methods, inorganic chemistry, etc., can solve the problems of long synthesis time, waste, environmental pollution, etc., to improve synthesis efficiency, reduce preparation costs, and improve efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0067] Mix tetraethyl orthosilicate and tetrabutyl titanate evenly, and then add the mixed solution to the aqueous solution of tetrapropyl ammonium hydroxide and mix evenly, wherein tetraethyl orthosilicate, tetrabutyl titanate, tetrapropyl The molar ratio of basic ammonium hydroxide to water is 1:0.035:0.25:85, hydrolyzed at normal pressure and 40° C. for 2 hours to obtain titanium and silicon hydrolysis solution.

[0068] Add cetyltrimethylammonium bromide to the obtained titanium and silicon hydrolyzate, mix the hydrolysis solution of titanium and silicon with the ratio of 25:1 by weight of cetyltrimethylammonium bromide, and quickly There is agglomeration of solid particles.

[0069] Filter out the solid particles and put them into a stainless steel sealed reaction vessel, crystallize at 170°C under autogenous pressure for 24 hours, filter the resulting crystallized product, wash with water, and dry at 110°C for 120 minutes, then in 550°C Calcined at ℃ for 3 hours to obta...

Embodiment 2

[0072] A proper amount of tetraethyl orthosilicate and tetraethyl titanate were added successively to the remaining filtrate in Example 1 at a molar ratio of 1:0.1, and solid particles agglomerated quickly. Filter out the solid particles and put them into a sealed stainless steel reaction vessel, crystallize at 170°C under autogenous pressure for 24 hours, filter the obtained crystallized product, wash with water, and dry at 110°C for 120 minutes, then in 550°C Calcined at ℃ for 3 hours to obtain TS-1 molecular sieve.

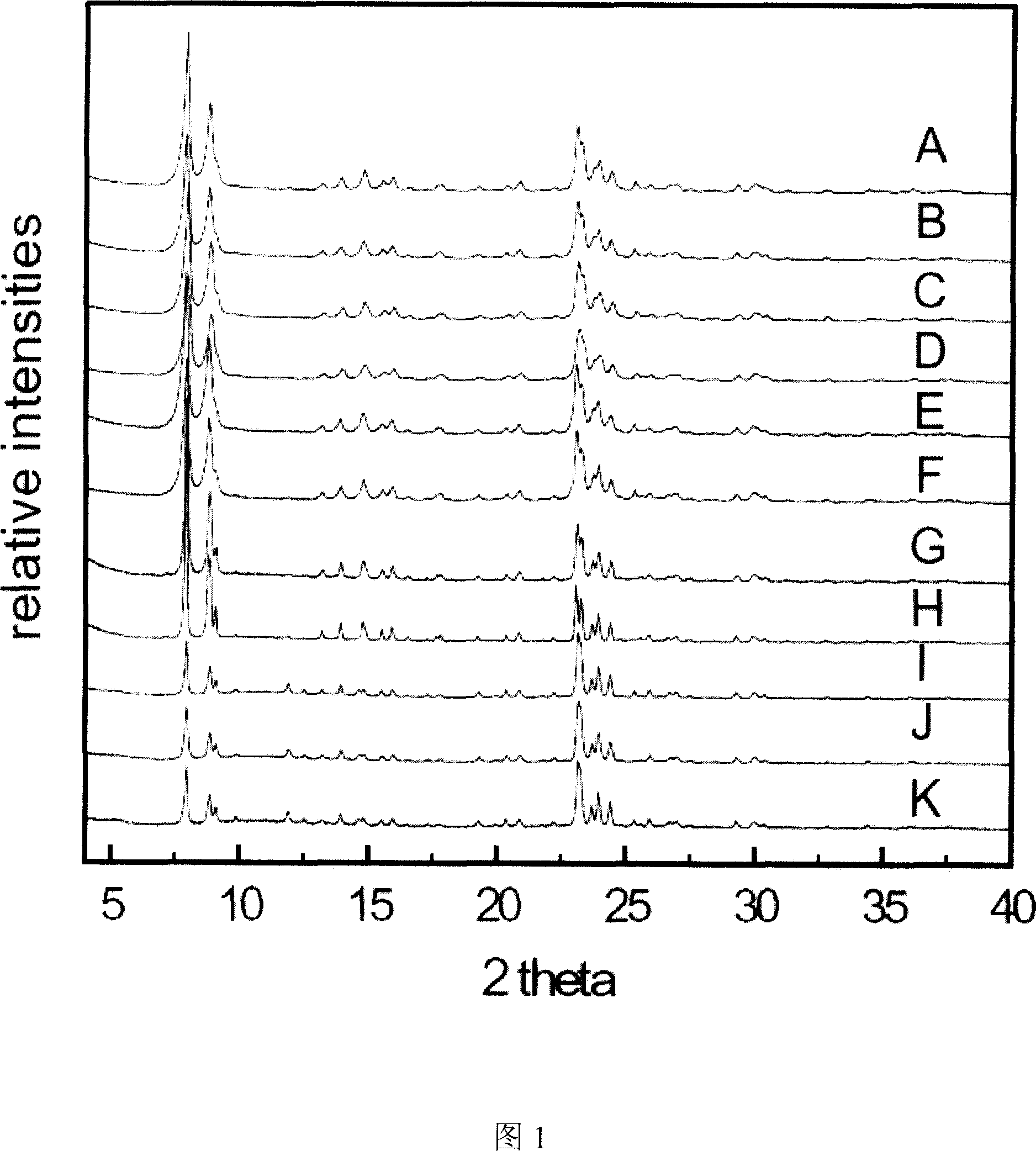

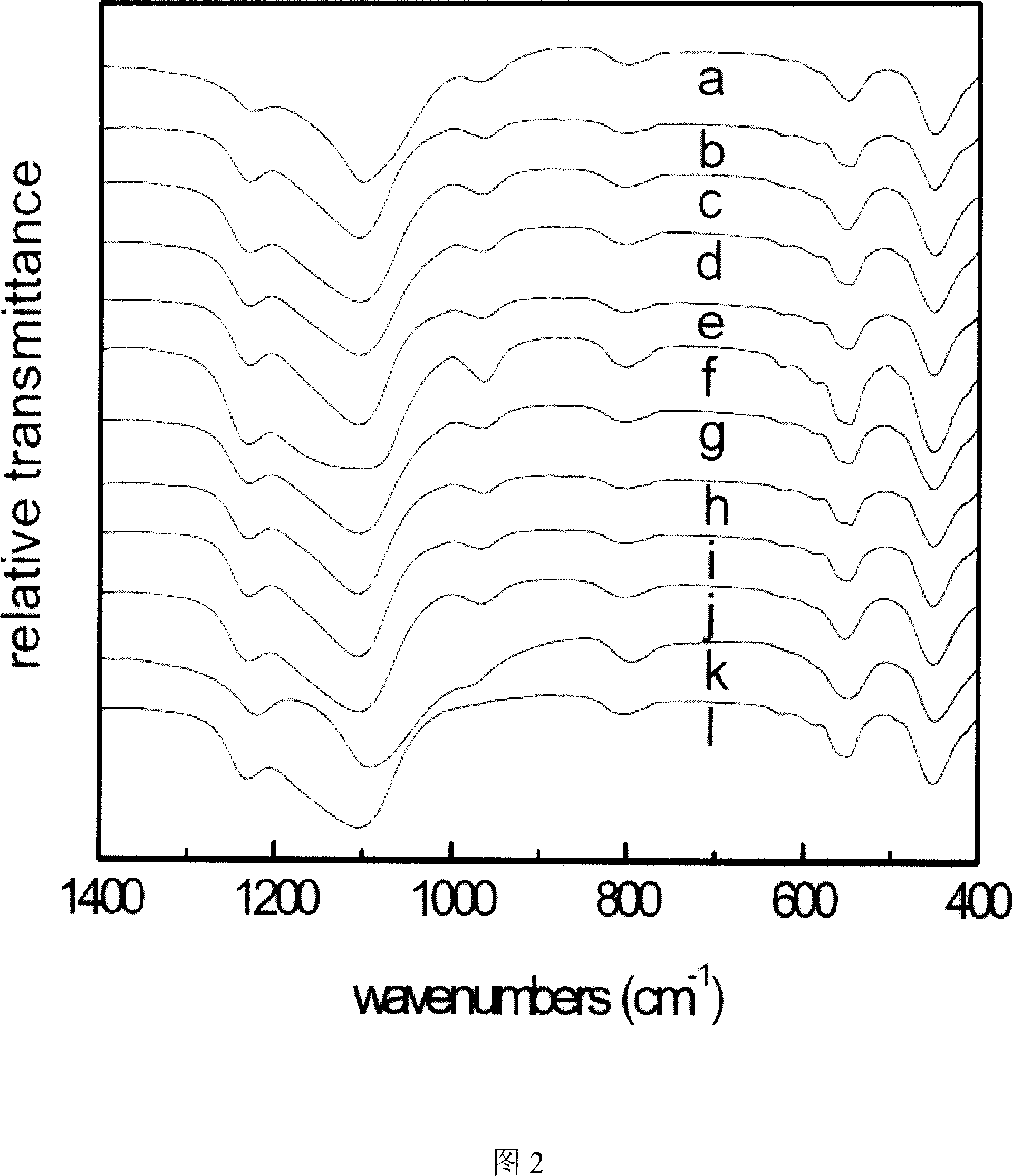

[0073] The XRD crystal phase diagram is as shown in Figure 1 (C), and the relative crystallinity is 96.4%; -1 The characteristic absorption peak that all-silicon molecular sieves do not have appears nearby, indicating that titanium has entered the molecular sieve framework.

Embodiment 3

[0075] An appropriate amount of tetrabutyl orthosilicate and tetraethyl titanate were added successively to the remaining filtrate in Example 2 at a molar ratio of 0.25:1, and solid particles agglomerated quickly. Filter out the solid particles and put them into a stainless steel sealed reaction kettle, stir and pre-crystallize at a temperature of 110°C and autogenous pressure for 2.5 hours, then raise the temperature to 170°C, continue to stir and crystallize for 24 hours, and the obtained crystallized product Filter, wash with water, dry at 110°C for 120 minutes, and then bake at 550°C for 3 hours to obtain TS-1 molecular sieve.

[0076] The XRD crystal phase diagram is as shown in Figure 1 (D), and the relative crystallinity is 96.1%; -1 The characteristic absorption peak that all-silicon molecular sieves do not have appears nearby, indicating that titanium has entered the molecular sieve framework.

PUM

| Property | Measurement | Unit |

|---|---|---|

| crystallinity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com