Storehouse type coal-burning boiler few-oil ignition combustion system

A coal-fired boiler, low-oil ignition technology, applied in the direction of burner, combustion type, combustion method, etc., can solve the problems of the safety operation of the power plant, affect the thermal efficiency of the boiler, and the heating surface is easy to coke, etc., to ensure safe and efficient operation, automatic Adapt to low-oil ignition and stable combustion, wide adaptability to coal types

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with the drawings and embodiments:

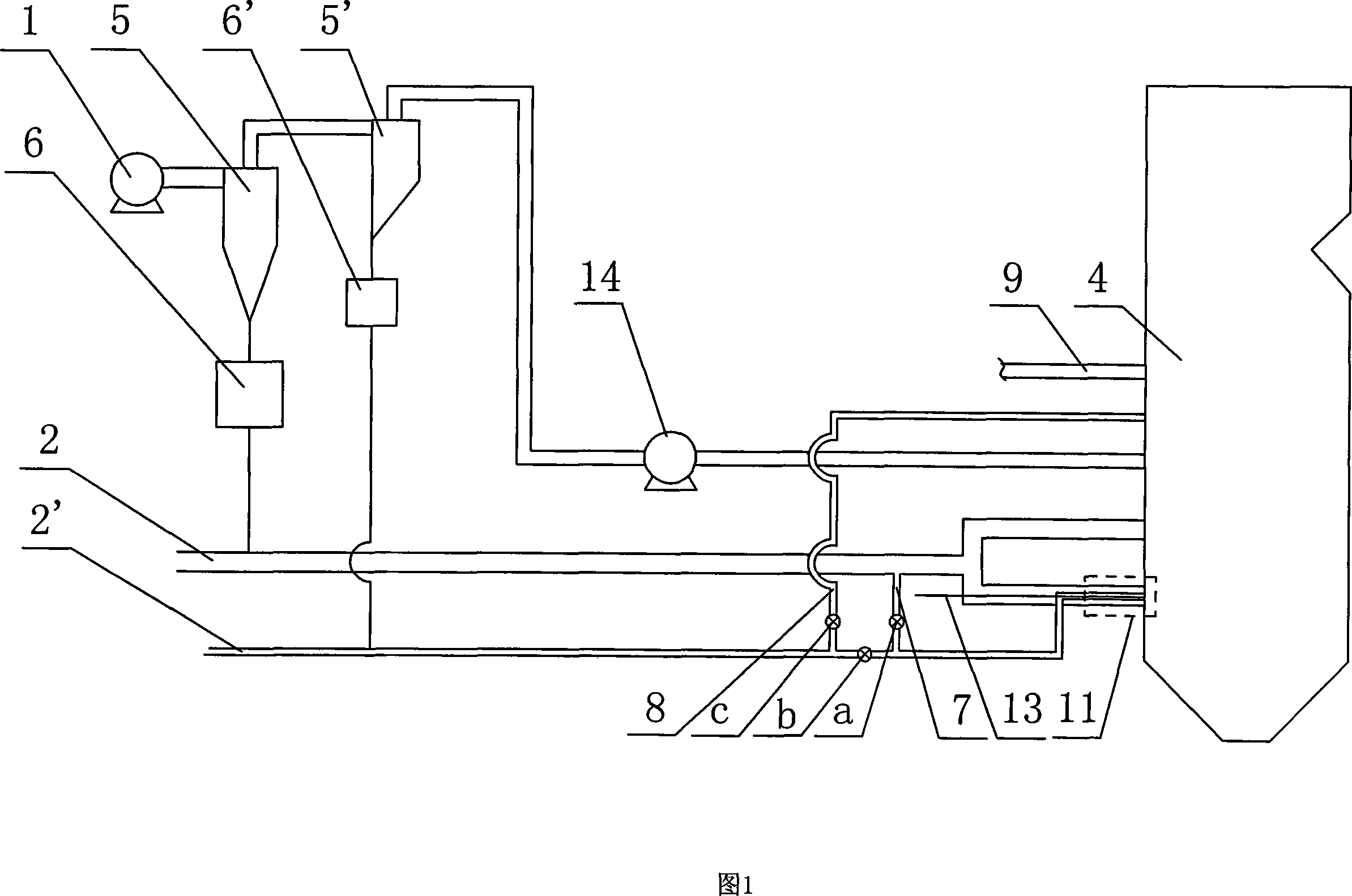

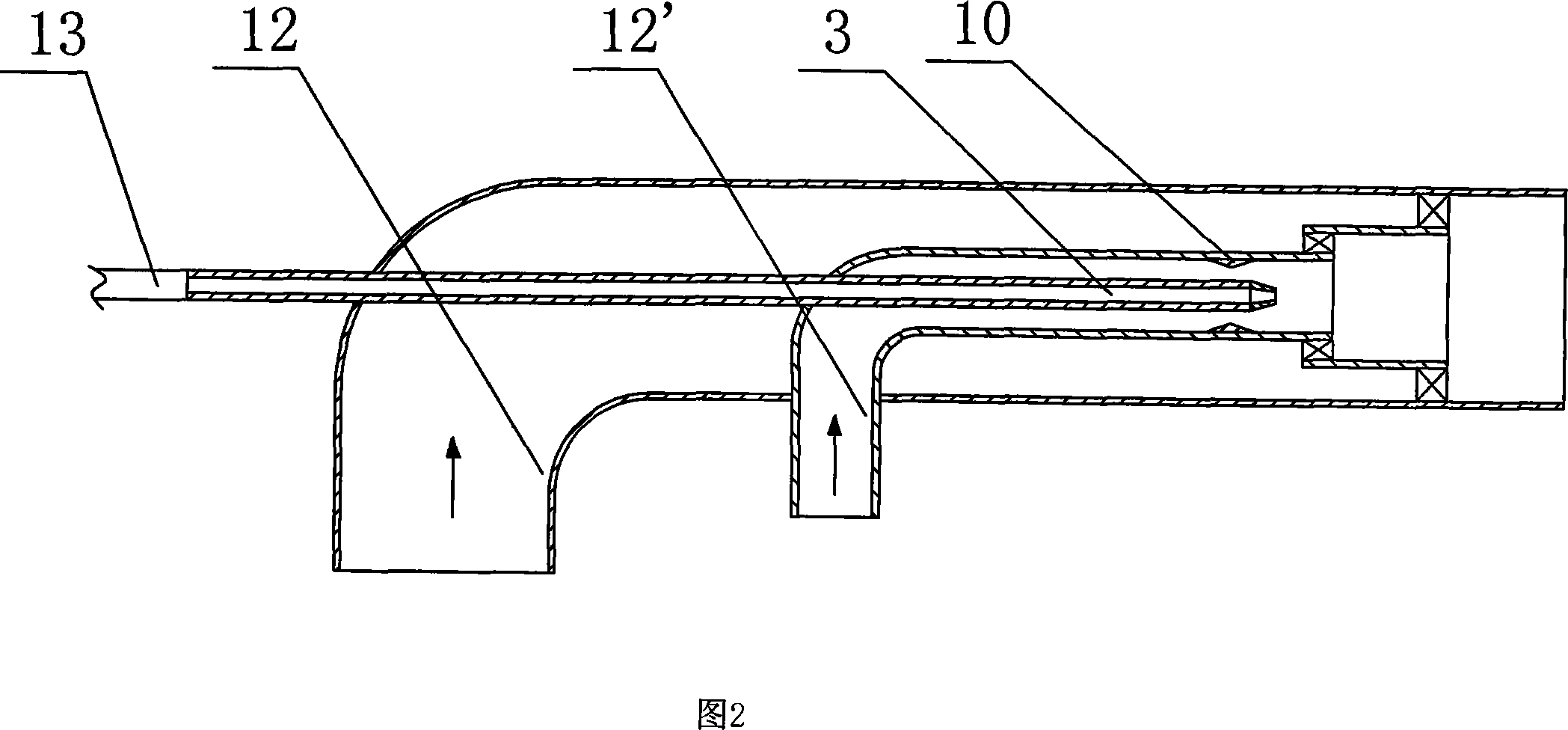

[0022] As shown in Figures 1 and 2, a low-oil ignition combustion system for a storage coal-fired boiler consists of a coal mill 1, a primary air main pipe 2, a primary air auxiliary pipe 2', a burner 11, a furnace 4, and a fine powder separator. 5. The ultrafine powder separator 5', the fine powder storage bin 6, the superfine powder storage bin 6'and the pipe 7, wherein the burner 11 is located in the lower part of the furnace 4, the burner 11 is composed of an external primary air duct 12 , The inner primary air pipe 12' and the oil gun 3 are composed, wherein the oil gun 3 is located on the main axis of the inner primary air pipe 12', and the nozzle of the oil gun 3 is close to the outlet of the inner primary air pipe 12'; 12' is located on the main axis of the outer primary air pipe 12, and the outlet of the inner primary air pipe 12' is close to the outlet of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com