Multifunctional universal ring kiln

A multi-functional, rotary kiln technology, applied in the field of rotary kiln, can solve the problems of lowering the sintering temperature, throwing too much coal in the side fire, collapsing and falling racks, etc., and achieves the effect of accelerating the cooling process, fast firing, and promoting heating.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

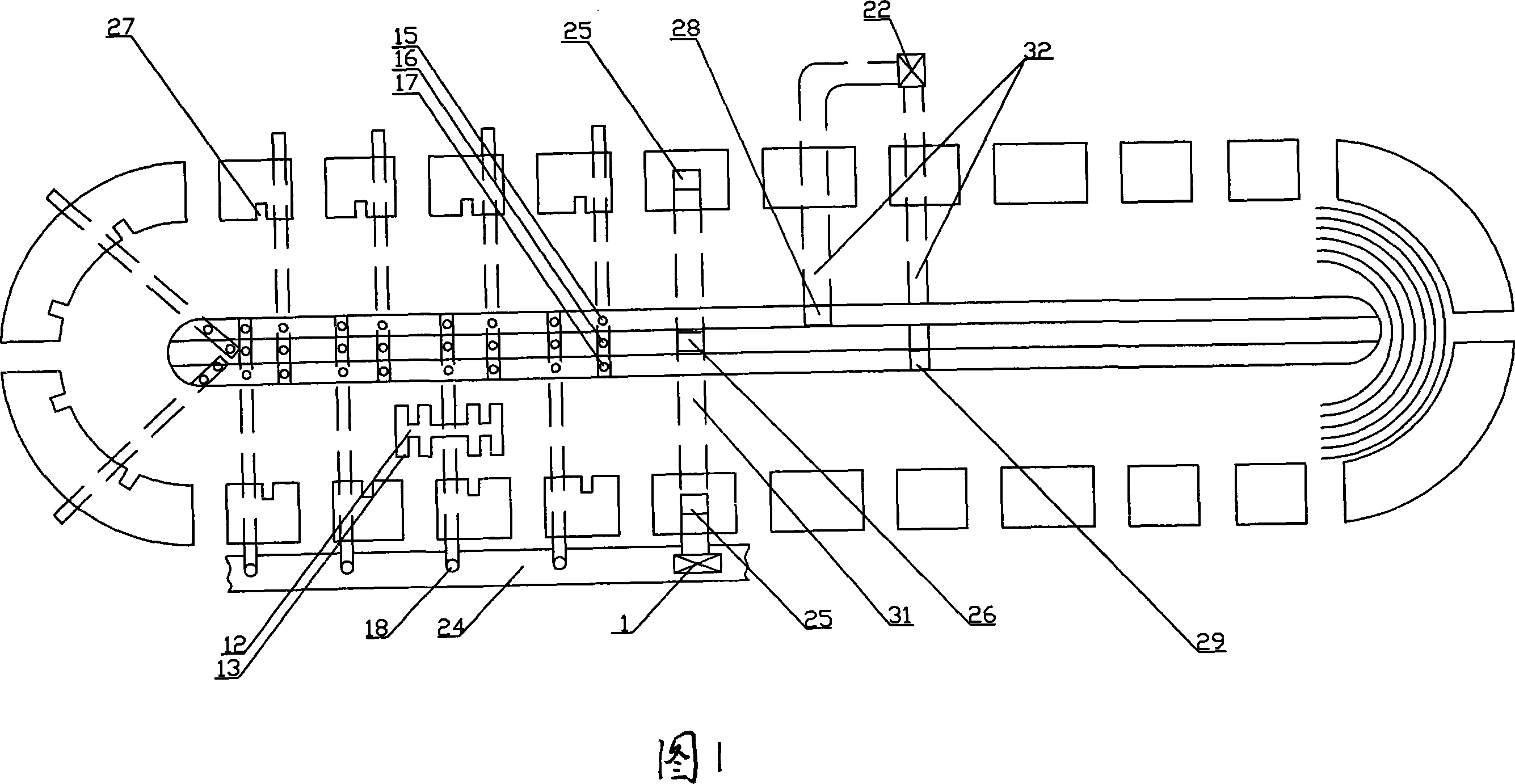

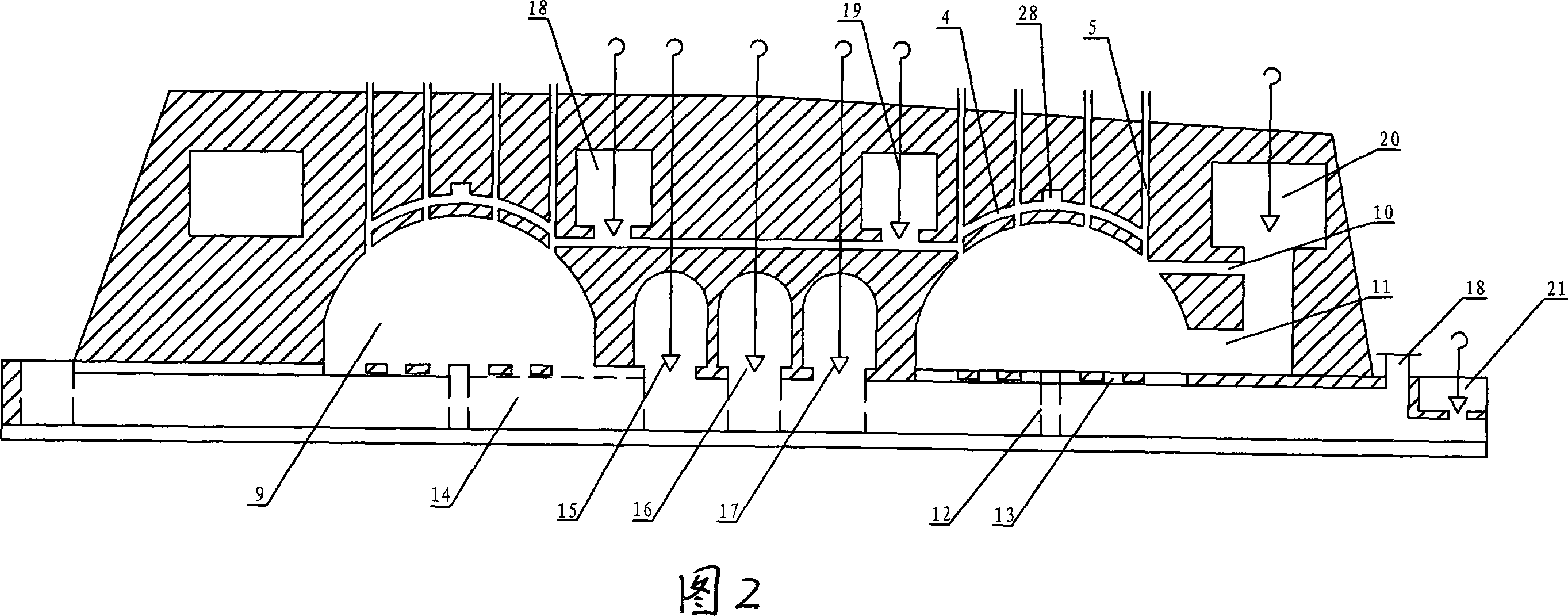

[0010] The present invention will be further elaborated below in conjunction with the accompanying drawings.

[0011] Fig. 1-Fig. 2 is the preferred scheme of the present invention, has shown the connected kiln chamber, total flue 32, exhaust fan 22, Kazakhstan outlet 10 and 11, gate, and the composition of exhaust duct, is characterized in that: connects the middle with exhaust fan 1 The total flue 32 and the outer ring flue 5 extract heat from the pretropical flue gas and enter the outer ring underground flue 6. After opening the gate, it is injected into the air outlet 7 at the bottom of the kiln chamber, and the flue gas is introduced into the roasting zone to make the black smoke After entering the kiln chamber for the second time, the high-temperature secondary combustion releases heat, eliminates black smoke, and achieves the effect of full combustion. Use the exhaust fan to connect the upper air duct and the lower air duct, extract the waste heat after roasting and tra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com