Novel micro nanometer electric spark and tunneling current composite processing device

A technology of tunnel current and combined processing, which is applied in the direction of microstructure devices, electric processing equipment, metal processing equipment, etc., and can solve the problems of micro-nano electric discharge machining and tunnel current that have not been reported.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

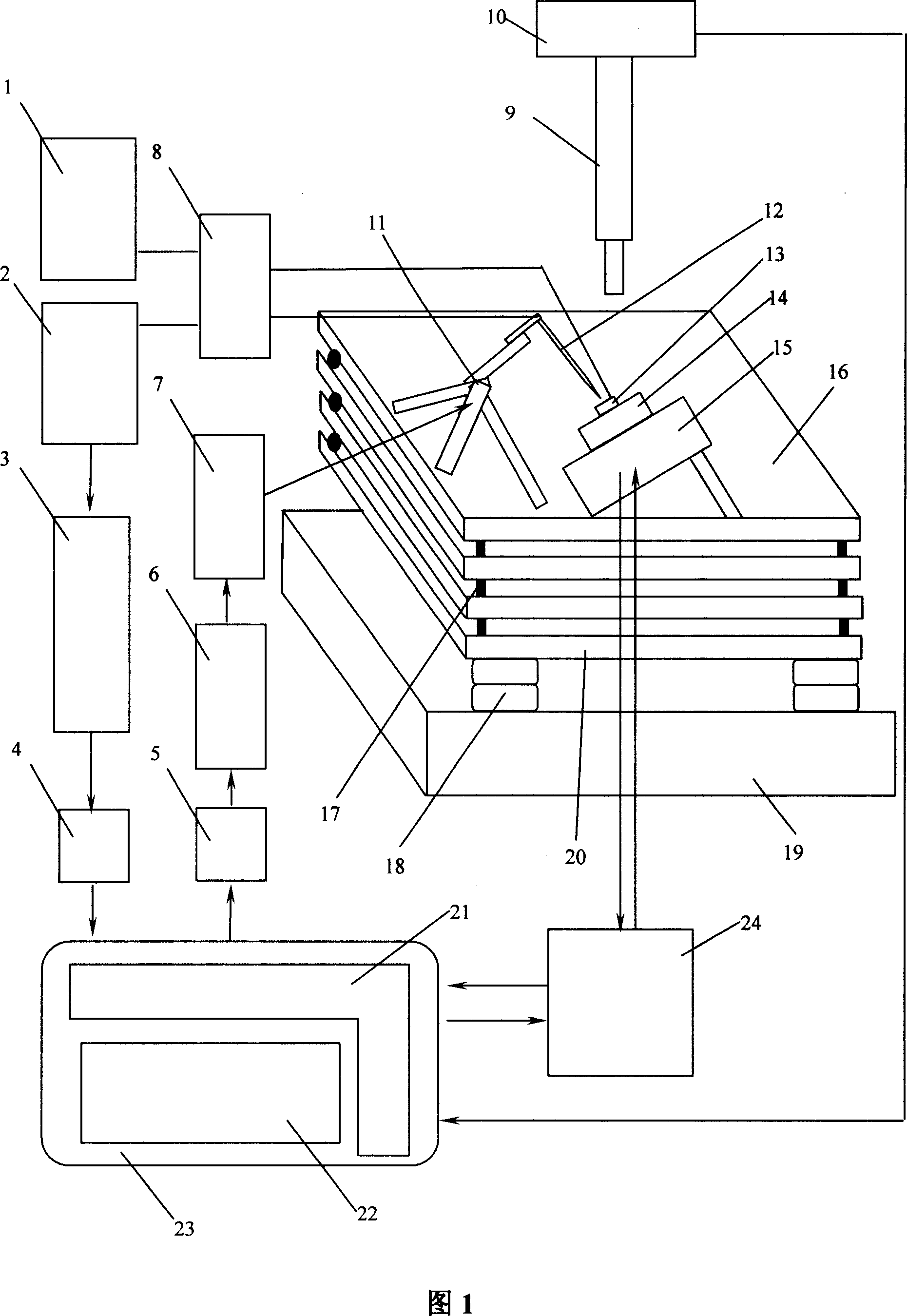

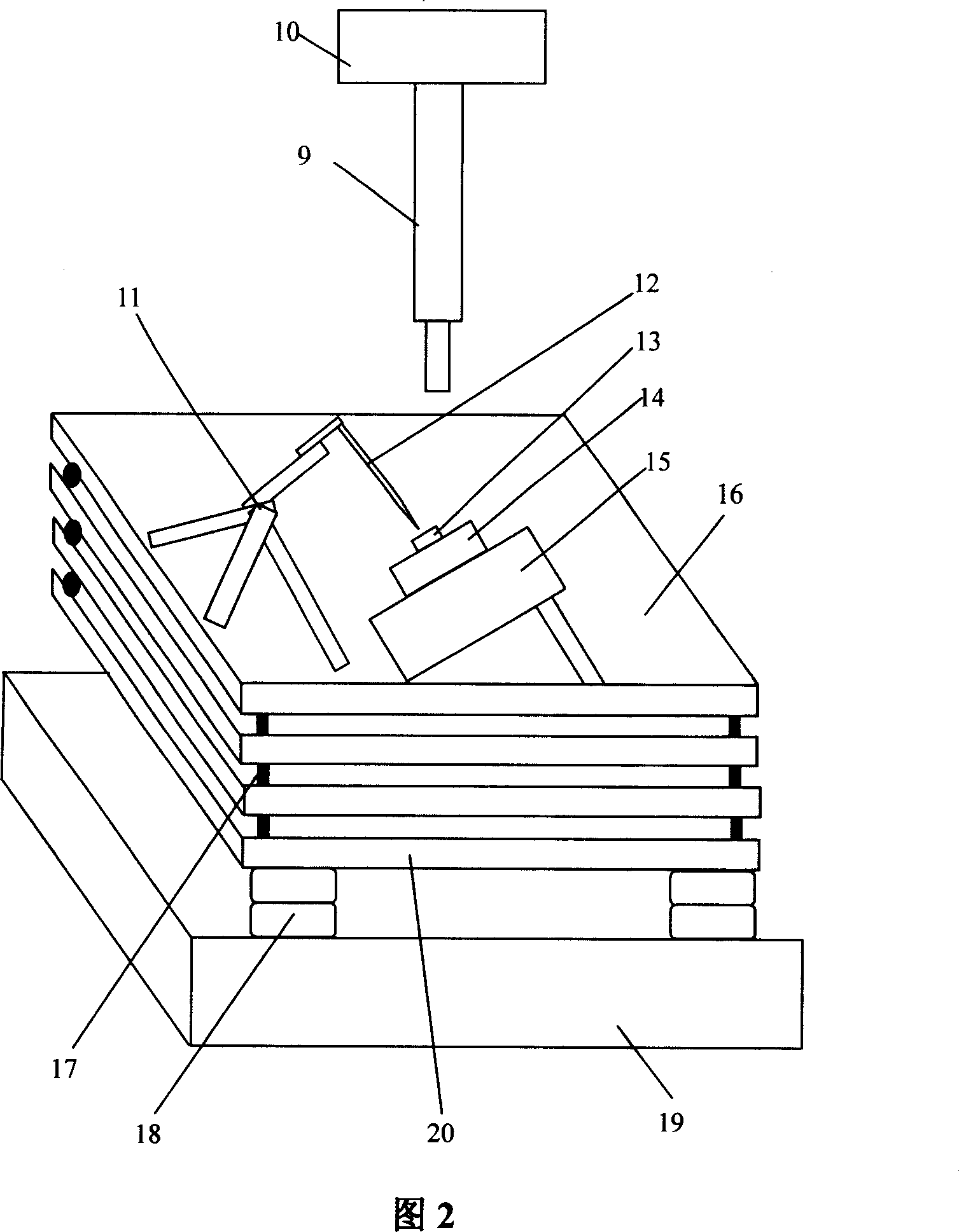

[0015] Embodiments of the present invention will be described below in conjunction with the accompanying drawings.

[0016] The technical device of the present invention includes a micro-nano electric discharge machining power supply 1, a scanning tunnel current machining power supply 2, a gap current or tunnel current amplifier 3, an A / D converter 4, a D / A converter 5, a piezoelectric ceramic control circuit 6, Electrode position fine-tuning controller 7, power switching controller 8, microscope system 9, CCD imaging system 10, electrode three-way piezoelectric fine-tuning mechanism 11, electrode or probe 12, workpiece 13, workpiece fine-tuning table 14, workpiece rough adjustment Workbench 15, shock-absorbing workbench 16, rubber column 17, shock-absorbing air cushion 18, base 19, steel plate 20, underlying control program 21, user interface 22, computer 23, workpiece motion servo and position feedback system 24.

[0017] The base 19 is the basis for the mechanical part of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com