Process for preparing rare ginsenoside Compound K by fermenting panax notoginseng saponins with streptomycete

A technology of notoginseng saponins and ginsenosides, applied in the fields of medicine and biology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

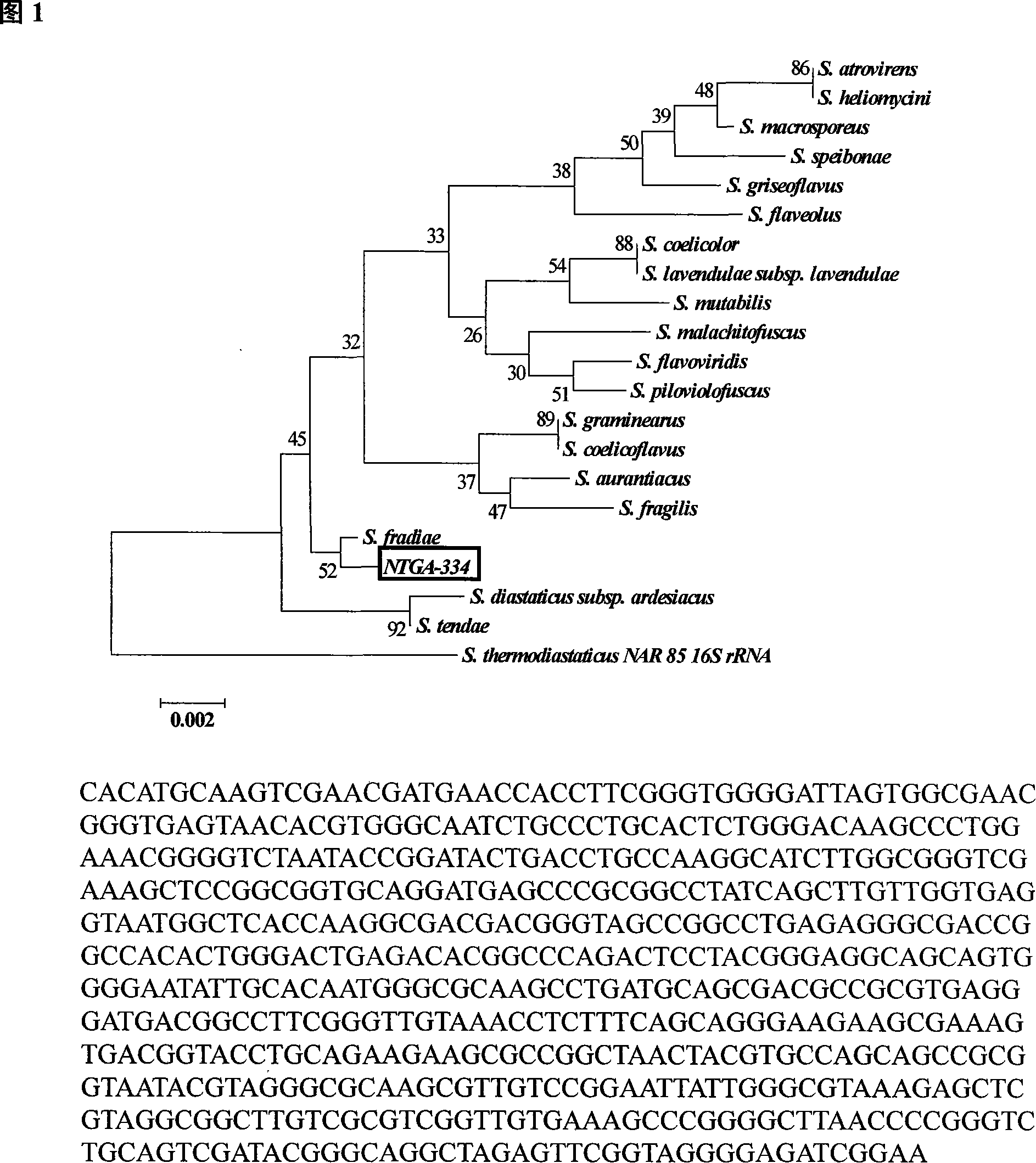

[0019] Example 1 Isolation of bacterial strains: cut the fresh notoginseng stems collected from Wenshan County, Yunnan Province into small sections (3-4cm), soak them in 70% alcohol for 0.5min, carry out surface disinfection, and then sterilize with 0.1% mercuric chloride Take it out for 8 minutes, wash it with sterile water 4 to 5 times, inoculate it on MS medium of plant tissue, firstly white granular hyphae with a diameter of 0.1-0.5mm will appear around the incision of the stem of Panax notoginseng, and gray powder will appear on the mycelia after 6 days spores and cover the stem cut. Pick the gray spores from the stem and place them on the escin-iron citrate plate medium, and after culturing at 28°C for 12 hours, irregular light brown-green hydrolysis circles appear, indicating that the strain has extracellular β-glucosidase activity. Inoculate the gray spores at the stems into the solid medium of Panax notoginseng powder for cultivation, and continue to transfer after a ...

Embodiment 2

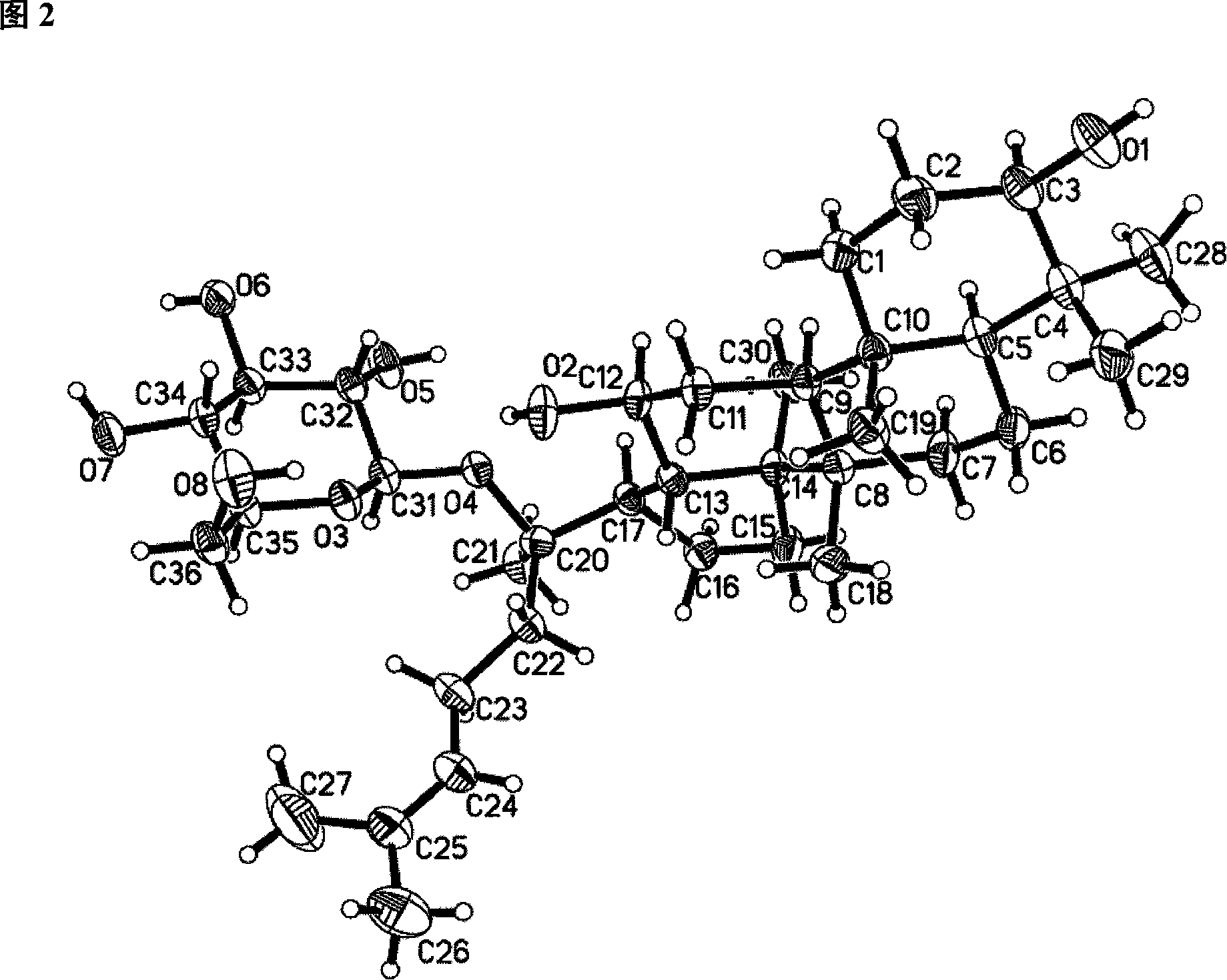

[0020] Example 2 Streptomyces fradiae NTGA-334 was transferred from Gaoshi No. 1 slant to ISP2 seed medium containing 1% (w / v) Panax notoginseng saponins, cultured at 28°C for 12h; then inoculated Into 60L humic acid culture medium containing 3000g Panax notoginseng saponins, and ferment at 28°C in a 100L fully automatic fermenter. After 36 hours, adjust and increase the ventilation ratio to 1:3 (v / v), and adjust the stirring rate to 400r / min. After 48 hours, adjust the fermentation temperature to 40°C, and dynamically adjust the pH to 5.0 with 5% (w / v) ammonia water. After 72 hours of fermentation, add Amberlite XAD-16 macroporous adsorption resin at 3% (w / v), stir for 2 hours, and put Can. The fermented liquid was filtered through a filter cloth to obtain a precipitate with a wet weight of 5112 g. The precipitate was ultrasonically extracted with 30 L of ethanol (95%) for 2 hours and filtered through a filter cloth. The filter residue was washed 5 times with 1 L of ethanol ...

Embodiment 3

[0021] Example 3 Streptomyces fradiae NTGA-334 was transferred from Gaoshi No. 1 slant to ISP2 medium containing 1% (w / v) Panax notoginseng saponins, cultured at 28°C for 12h; then inoculated In the 60L humic acid medium containing 3000g of Panax notoginseng saponins, ferment at 28°C in a 100L fully automatic fermenter. After 36 hours, adjust and increase the ventilation ratio to 1:2 (v / v), and adjust the stirring rate to 350r / min. After 48 hours, adjust the fermentation temperature to 38°C, and dynamically adjust the pH to 5.0 with 5% (w / v) ammonia water. After 96 hours of fermentation, add DH101 macroporous adsorption resin at 4% (w / v), stir for 4 hours, and put it into the tank. The fermented liquid was filtered through a filter cloth to obtain a precipitate with a wet weight of 5909 g. The precipitate was ultrasonically extracted with 20 L of ethanol (95%) for 3 h and filtered through a filter cloth. The filter residue was washed 5 times with 1 L of ethanol (95%). The eth...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com