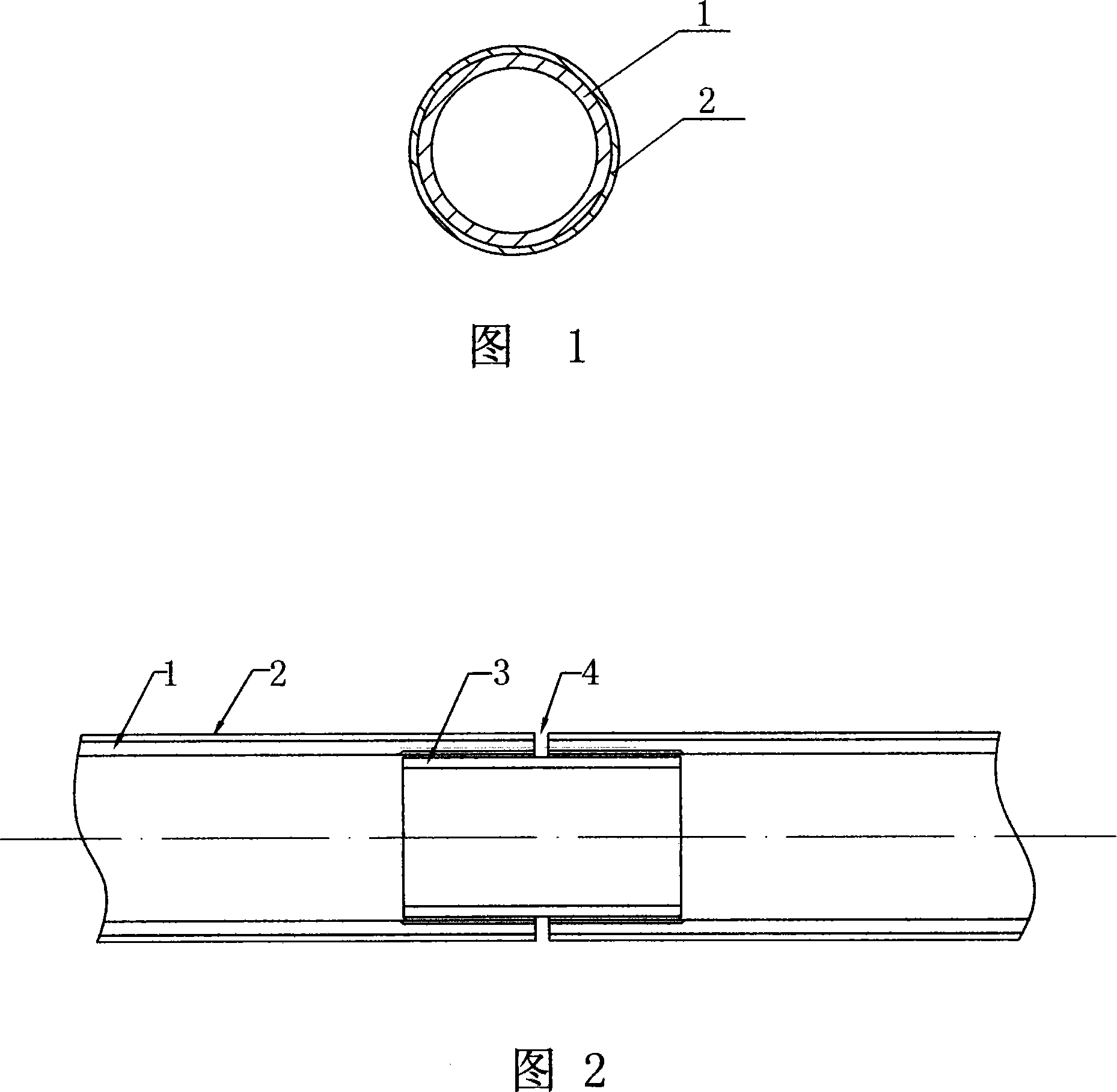

Method for producing improved radio-frequency cable inner conductor pipe

A processing method and technology of radio frequency cables, which are applied in the direction of single-tube conductors, metal/alloy conductors, and plating of superimposed layers, and can solve problems such as the impact of communication effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] (1), configuration of degreasing liquid, degreasing and cleaning: the percentage content is 10% NaOH solution, 30% NaOH 3 PO 4 solution, 15% Na 2 CO 3 The degreasing liquid is prepared by mixing the volume ratio of 1:1:1, the finished aluminum tube is placed in the degreasing liquid to remove oil, and then the degreased aluminum tube is rinsed with tap water;

[0024] (2), nitric acid light emission: treat with a nitric acid solution with a percentage content of 33.3%, and then rinse the aluminum tube with water;

[0025] (3), zinc dipping: the content is 110 g / liter sodium hydroxide solution, 50 g / liter zinc oxide solution, 1 g / liter ferric chloride solution, 4 g / liter potassium sodium tartrate solution in the same volume Mix to make a zinc dipping solution; soak the aluminum tube processed in step (2) in the zinc dipping solution for 3 minutes, then rinse with water;

[0026] (4), nitric acid dezincification: the aluminum tube processed through step (3) is dezinci...

Embodiment 2

[0035] (1), configuration of degreasing liquid, degreasing and cleaning: the percentage content is 20% NaOH solution, 40% Na 3 PO 4 solution, 10% Na 2 CO 3 The degreasing liquid is obtained by mixing the degreasing liquid at a volume ratio of 1:1:1. Put the finished aluminum pipe in the degreasing liquid to remove the oil, and then rinse the degreased aluminum pipe with tap water;

[0036] (2), nitric acid light emission: treat with a nitric acid solution with a percentage content of 33.3%, and then rinse the aluminum tube with water;

[0037] (3), immersion zinc; the sodium hydroxide solution that content is 125 grams / liter, 48 grams / liter zinc oxide solution, 1 gram / liter ferric chloride solution, 5 grams / liter potassium sodium tartrate solution are pressed the same volume Mixing and making zinc dipping solution; soaking the aluminum tube processed in step (2) in the zinc dipping solution for 4 minutes, then rinsing with water;

[0038] (4), nitric acid dezincification: ...

Embodiment 3

[0047] (1), configuration of degreasing liquid, degreasing and cleaning: the percentage content is 15% NaOH solution, 50% NaOH 3 PO 4 solution, 20% Na 2 CO 3 The degreasing liquid is obtained by mixing the degreasing liquid at a volume ratio of 1:1:1. Put the finished aluminum pipe in the degreasing liquid to remove the oil, and then rinse the degreased aluminum pipe with tap water;

[0048] (2), nitric acid light emission: treat with a nitric acid solution with a percentage content of 33.3%, and then rinse the aluminum tube with water;

[0049] (3), immersion zinc; With content be 150 grams / liter sodium hydroxide solution, 52 grams / liter zinc oxide solution; 1 gram / liter ferric chloride solution, 6 grams / liter potassium sodium tartrate solution by the same volume Mixing and making a zinc dipping solution; soaking the aluminum tube processed in step (2) in the zinc dipping solution for 5 minutes and then rinsing with water;

[0050] (4), nitric acid dezincification: the al...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com