Mask alignment making and aligning used for light scribing device

An alignment mark and mask alignment technology, which is applied in photoplate-making process exposure devices, microlithography exposure equipment, optics, etc. The effect of improved capture capability, high capture probability, and high repeatability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

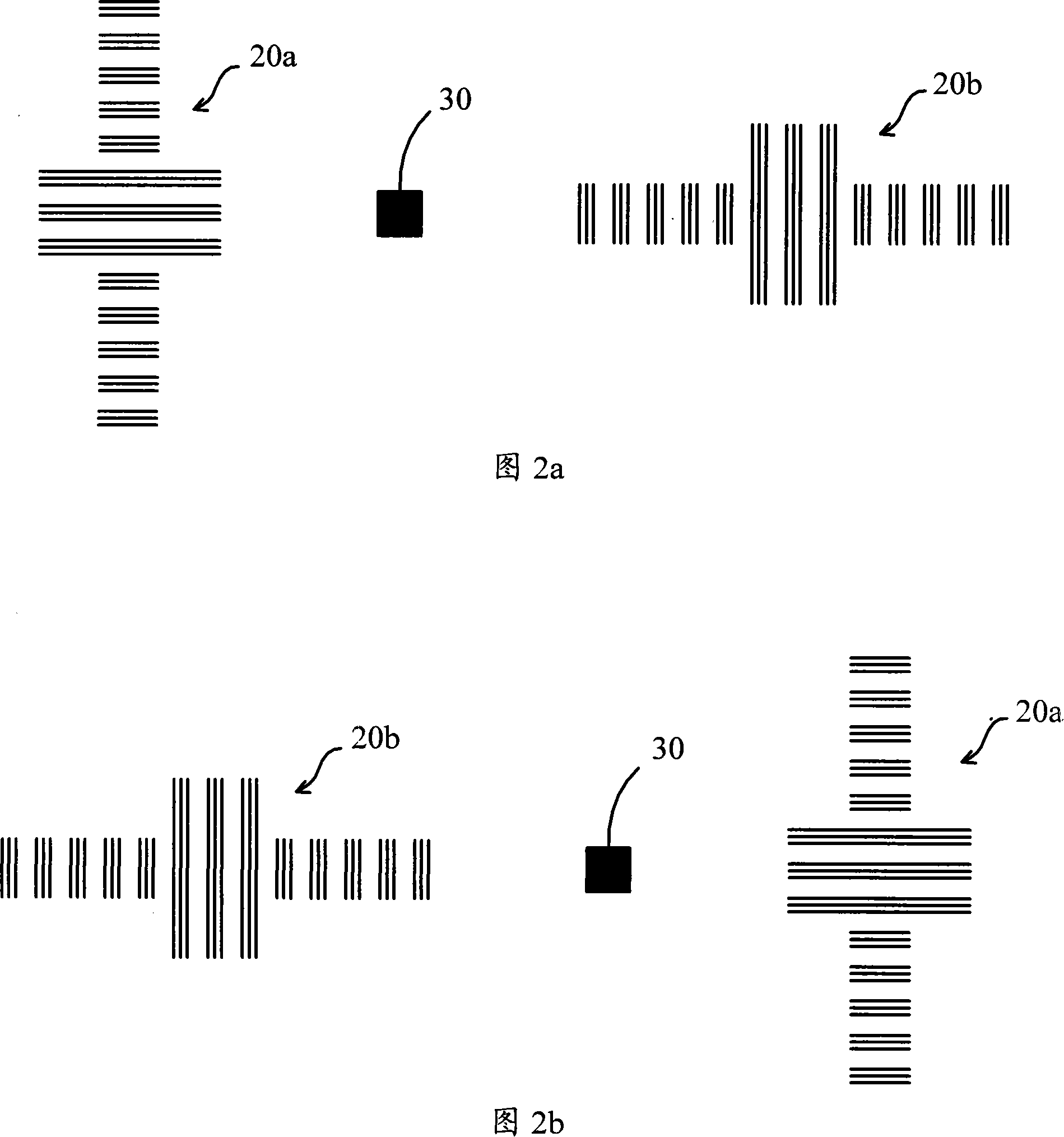

[0021] A mask alignment mark placed on the mask of the mask table and the reference plate of the workpiece table is a transmission alignment mark combination composed of a plurality of alignment mark branches, and the mark combination is used to provide The mask is optically aligned.

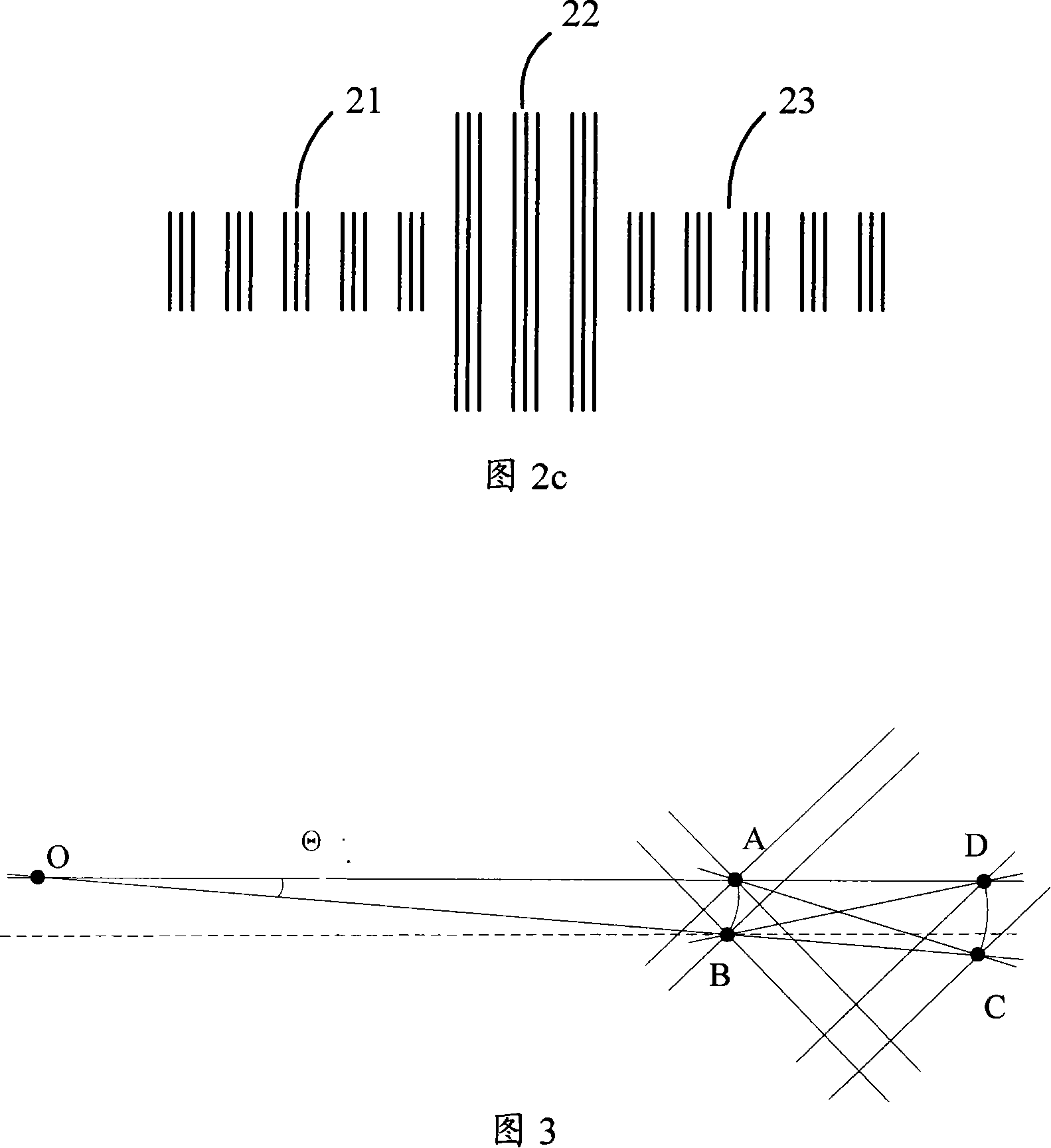

[0022] As shown in FIG. 2a and FIG. 2b, the mask alignment mark includes a first alignment mark branch 20a, a second alignment mark branch 30 and a third mark branch 20b, the first and third alignment mark branches 20a, 20b are mutually rotated by 90°; the graphics of the second alignment mark branch 30 in the transmission alignment mark on the workpiece table reference plate are distributed in the shape of square transmission holes, and the other two alignment mark branches 20a and 20b are used for alignment scanning Before, the aerial image corresponding to the second alignment mark branch 30 in the transmission alignment mark on the mask is scanned by scanning the aerial image corresponding t...

Embodiment 2

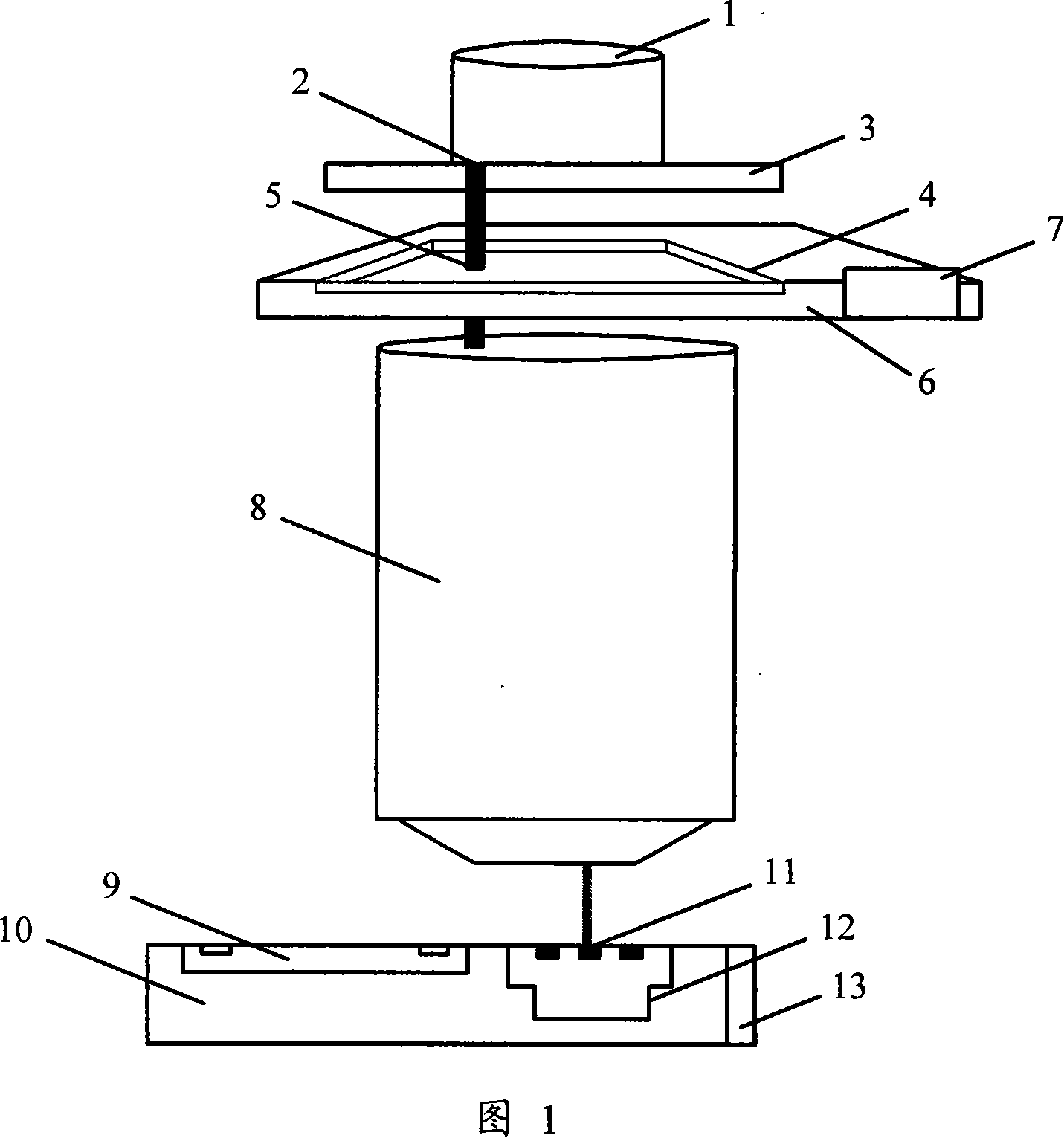

[0027] A method for aligning a photolithographic device. In the alignment system of the lithography apparatus shown in FIG. 1 , the alignment position is obtained from the model by calculating the parameters of the relationship model between the radiation and the relative position between the mask and the workpiece table.

[0028] The flow of the mask alignment method using the above-mentioned mask alignment marks will be described in detail below with reference to FIG. 1 to FIG. 4 . Point O in Figure 3 is the geometric center of the workpiece table, and the specific steps are as follows:

[0029] 1. Use the second alignment mark branch 30 in the transmission alignment mark 12 on the workpiece table reference plate to perform a rough scan on the second alignment mark branch 30 in the transmission alignment mark 5 on the mask to capture the entire transmission alignment mark, The approximate position of the transmission alignment mark is obtained, wherein the three alignment m...

Embodiment 3

[0037] Referring to Fig. 1 to Fig. 4, another method for aligning a lithographic apparatus of the present invention includes the following steps:

[0038] (a) Use the second alignment mark branch in the mask alignment mark on the workpiece table reference plate to perform rough capture scanning on the aerial image of the second alignment mark branch in the alignment mark on the mask, and use the detected calculating the radiation information, the position information of the mask and the position information of the workpiece table to obtain the coarse center position of the combination of transmission alignment marks;

[0039] (b) Use the first alignment mark branch on the workpiece table reference plate to perform single-layer or multi-layer rough scanning of the aerial image of the corresponding alignment mark branch on the mask in a direction perpendicular to it, and use the detected Calculating the radiation information, mask position information, and workpiece table positi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com