Device and method for preparing a homogeneous mixture consisting of fuel and oxidants

A homogeneous mixture, oxidant technology, applied in chemical instruments and methods, feeding devices, combustion methods, etc., can solve problems such as helpless rapid cold start, increased complexity, unfavorable dynamic operation, etc., to eliminate the need and reduce heat. Stress, the effect of avoiding spontaneous combustion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] In the following description of the preferred embodiments of the present invention, the same reference numerals denote the same or corresponding components.

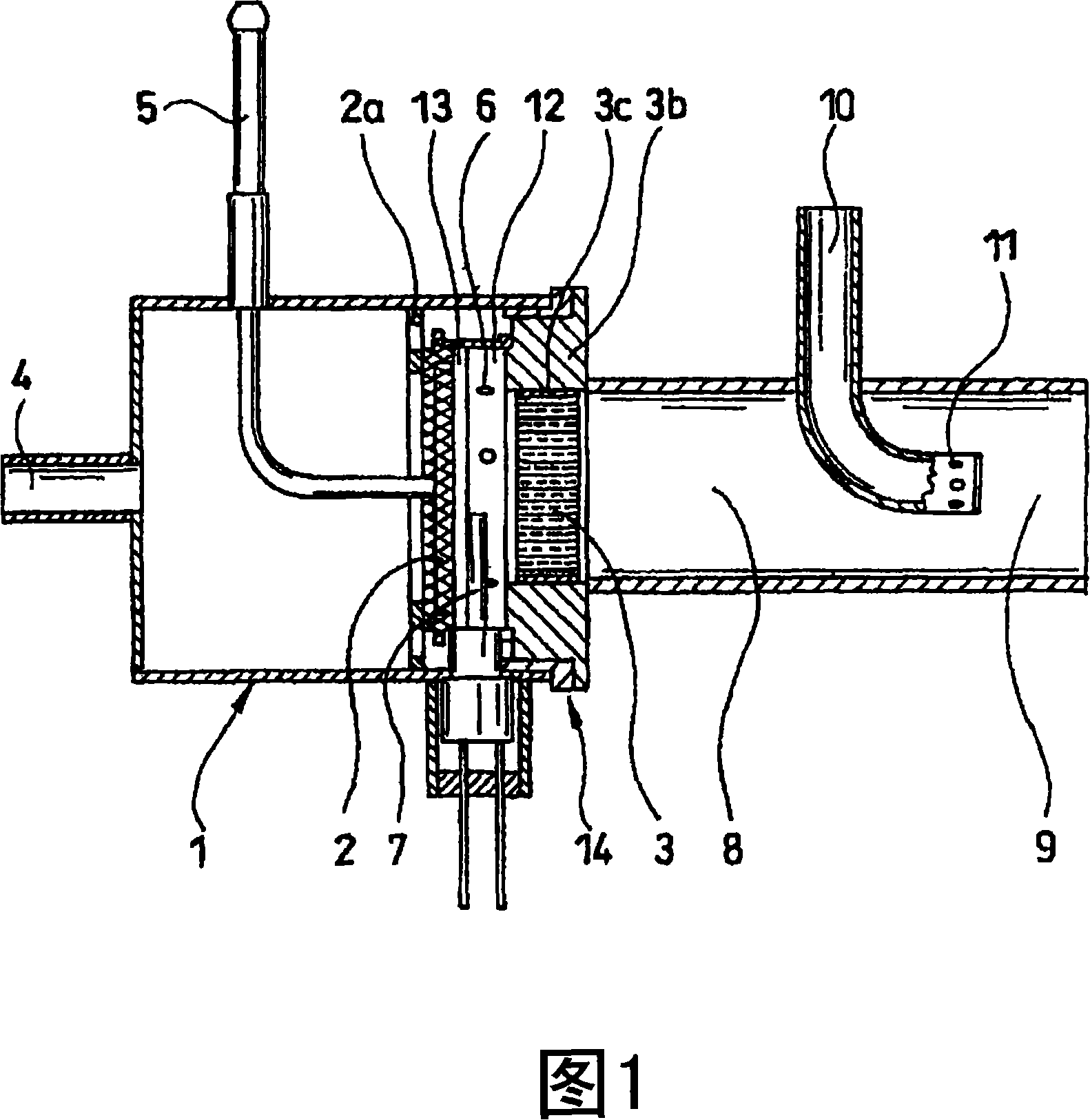

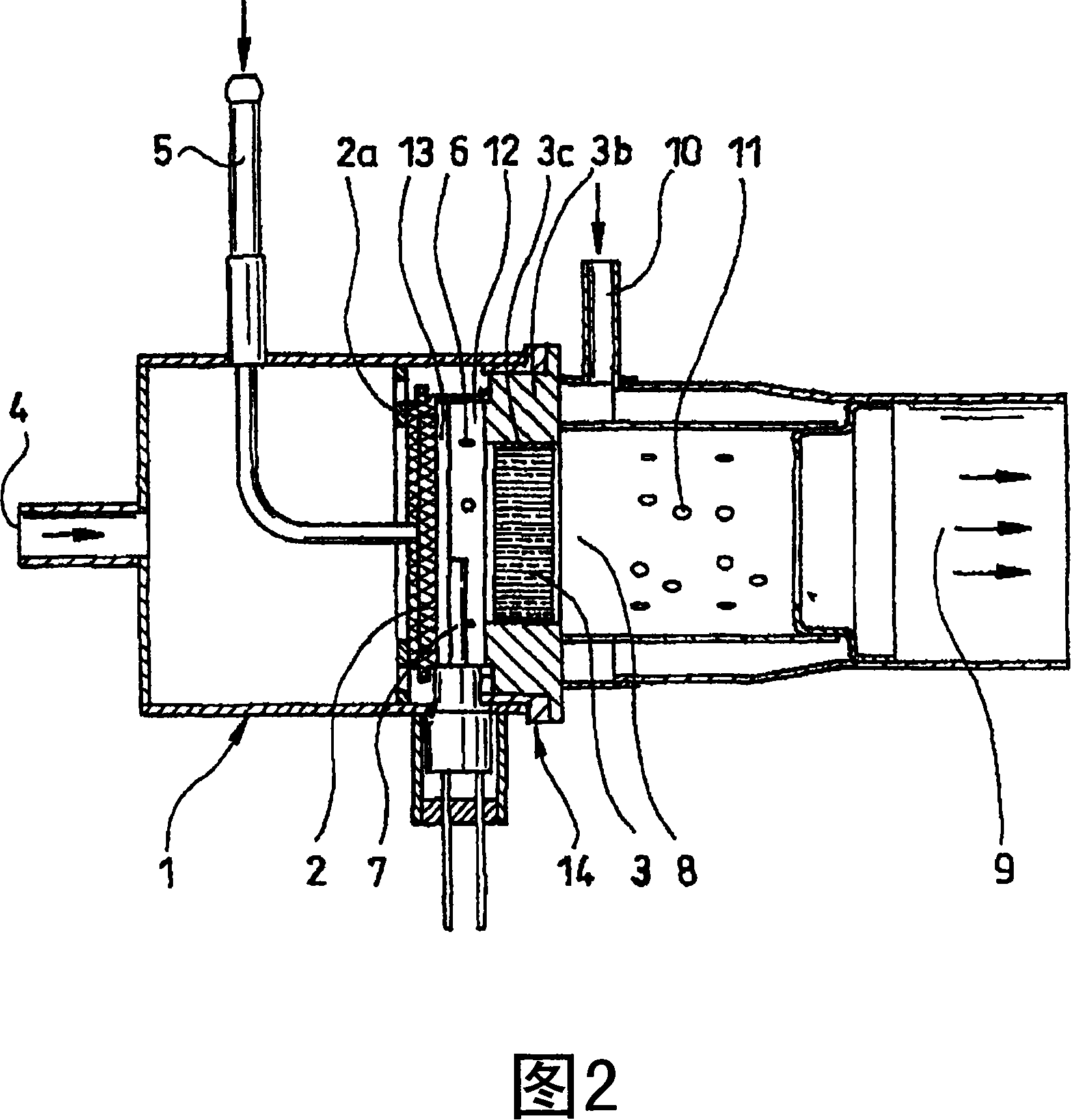

[0035] Referring now to Figure 1, there is shown a first embodiment of a system for providing a homogeneous fuel / air mixture on a liquid fuel basis. As shown in Figure 1, as an example, the core component of the system for providing a homogeneous fuel / air mixture on the basis of liquid fuel is the fuel evaporator 2 arranged in the evaporator element 1, the support element 3b is connected to the evaporator Element 2, for mounting a packed structure, which may be jacketed by a fiber mat 3c, for mechanical fixation and thermal insulation, respectively. Liquid fuel and oxidant are supplied to the system via fuel supply 5 and oxidant supply 4 respectively. An oxidant, preferably air, with optional additives such as steam, enters the mixing chamber 12 through the radially inwardly facing holes 6, where it mixes with th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com