TFT matrix structure and making method thereof

A technology of matrix structure and manufacturing method, which is applied in semiconductor/solid-state device manufacturing, optics, instruments, etc., can solve problems affecting channel width-to-length ratio, complex multi-step etching process, and change of TFT electrical characteristics, so as to reduce short circuit occurrence, saving chemical solution, and reducing channel residue

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

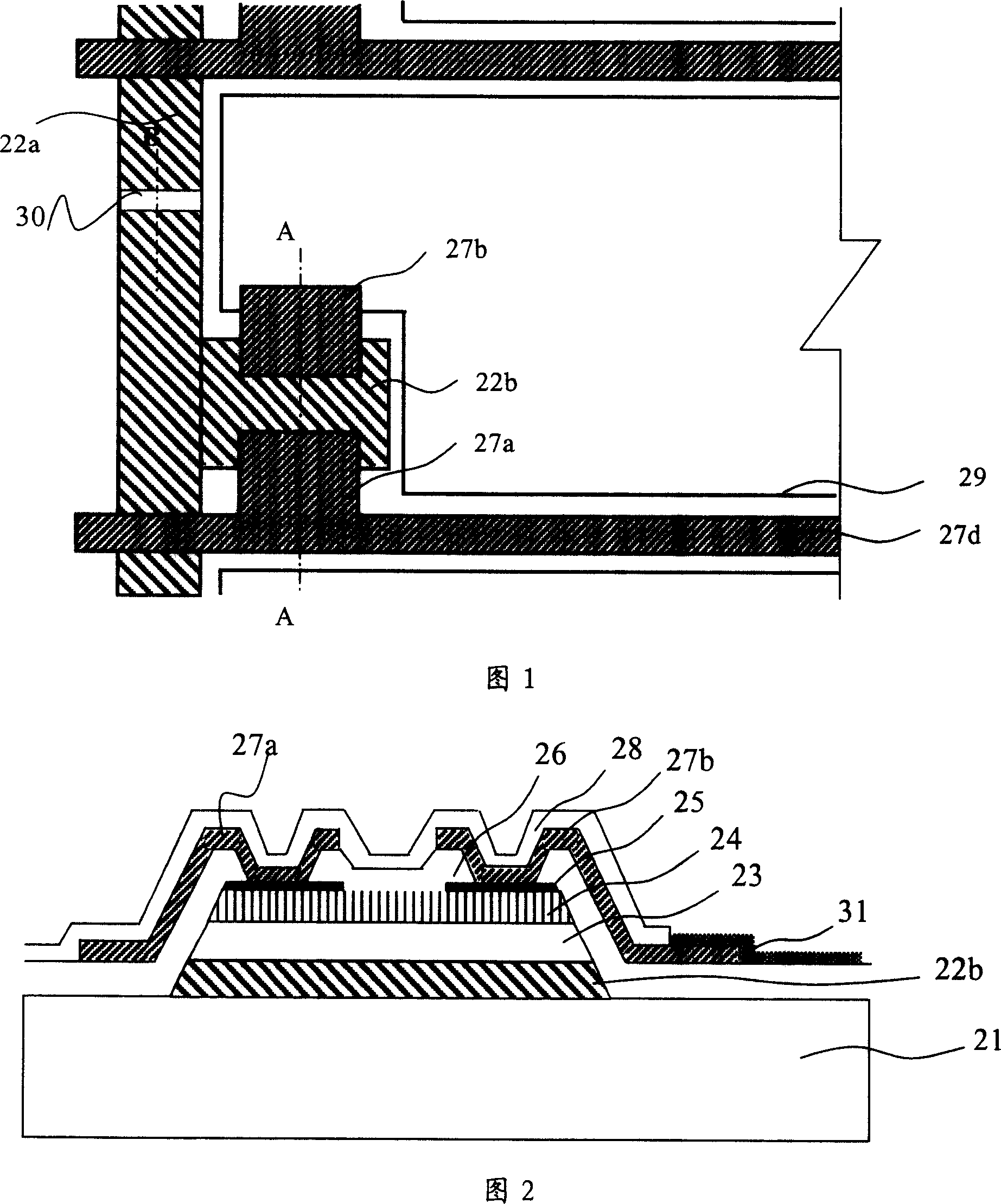

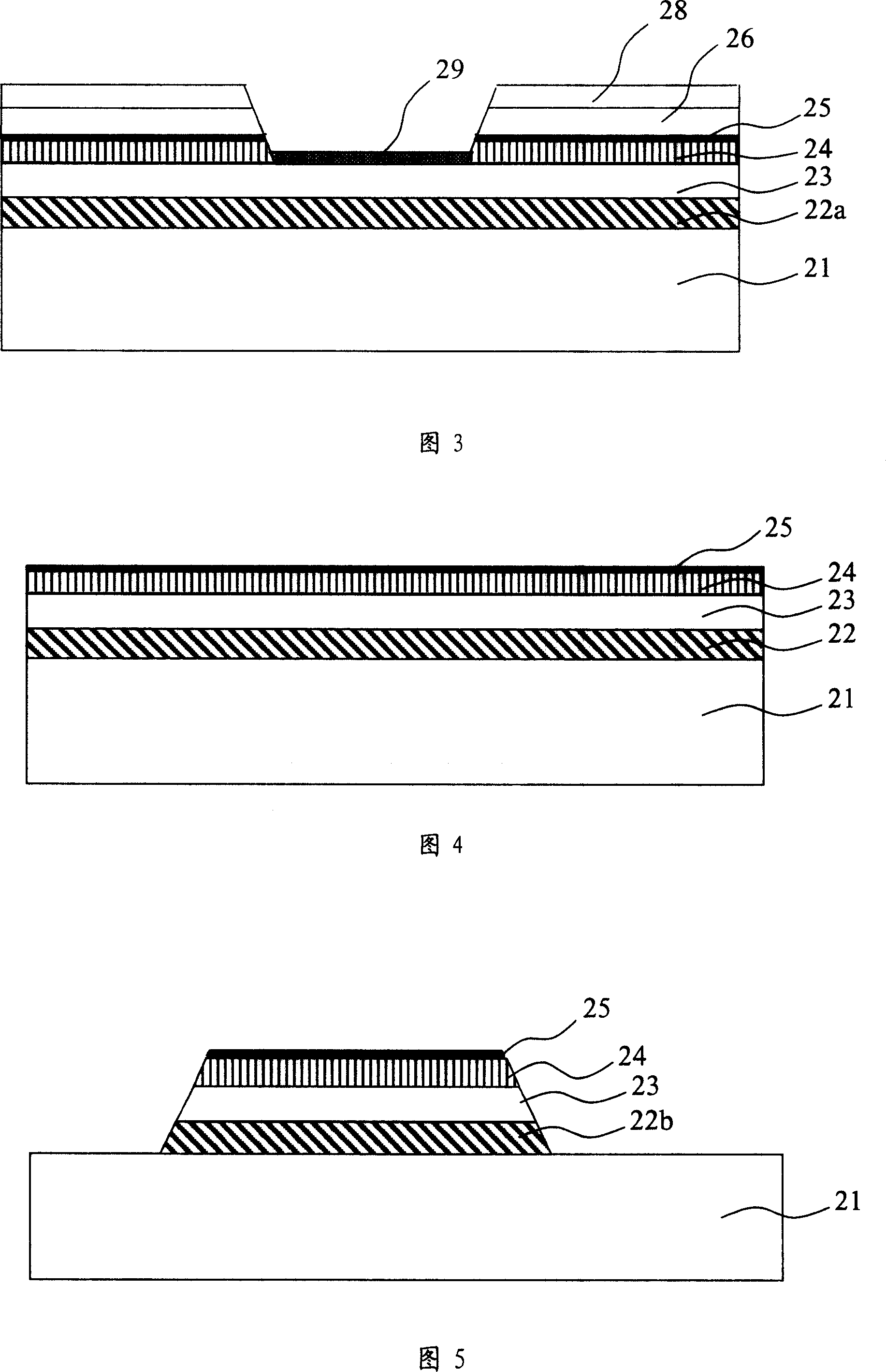

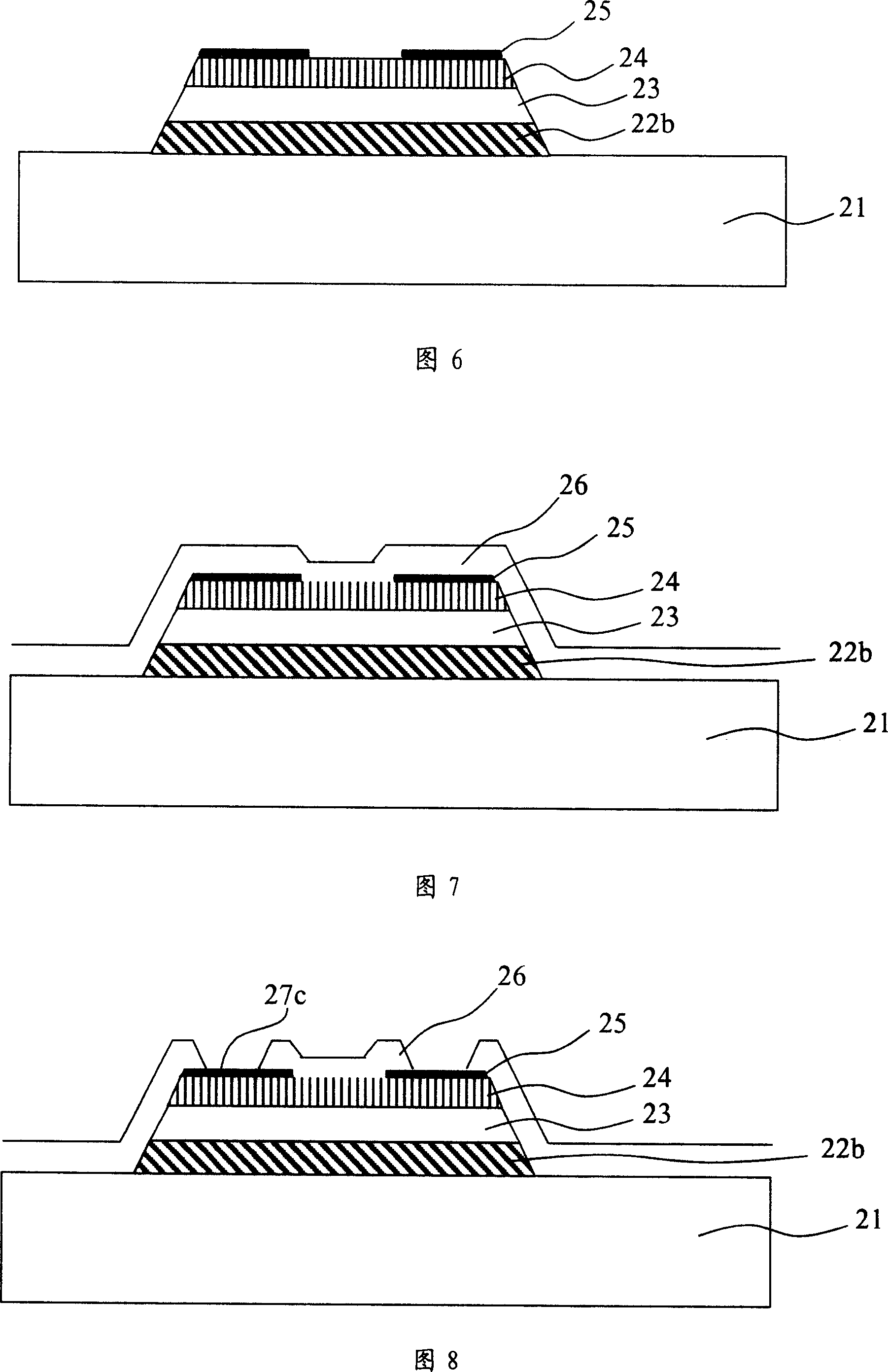

[0038] Fig. 1, Fig. 2 and Fig. 3 show the structure of the TFT matrix of the present invention.

[0039] As shown in Fig. 1, Fig. 2 and Fig. 3, the TFT matrix structure of the present invention comprises: a substrate 21; a gate line 22a and an integral gate electrode 22b formed on the substrate 21; above the gate line 22a and the gate electrode 22b Covered with a first layer of insulating layer 23, a semiconductor layer 24 and an ohmic contact layer 25 in sequence; the TFT channel is formed on the ohmic contact layer 25 on the gate electrode 22b; the second layer of gate insulating layer 26 is formed on the ohmic contact layer 25 the source-drain electrode via hole 27c is formed on both sides of the channel of the thin film transistor; the data line 27d and the source electrode 27a integrated with it are formed on the top of the second insulating layer 26, and pass through the source-drain electrode via hole 27c and the gate The ohmic contact layer 25 on the electrode 22b is c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com