Gas and solid powder mixture separator

A mixture and solid powder technology, applied in the field of gas and solid mixture separation devices, can solve the problems of large one-time investment, high price, complex structure, etc., and achieve the effects of large processing flow, simple structure and simple system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

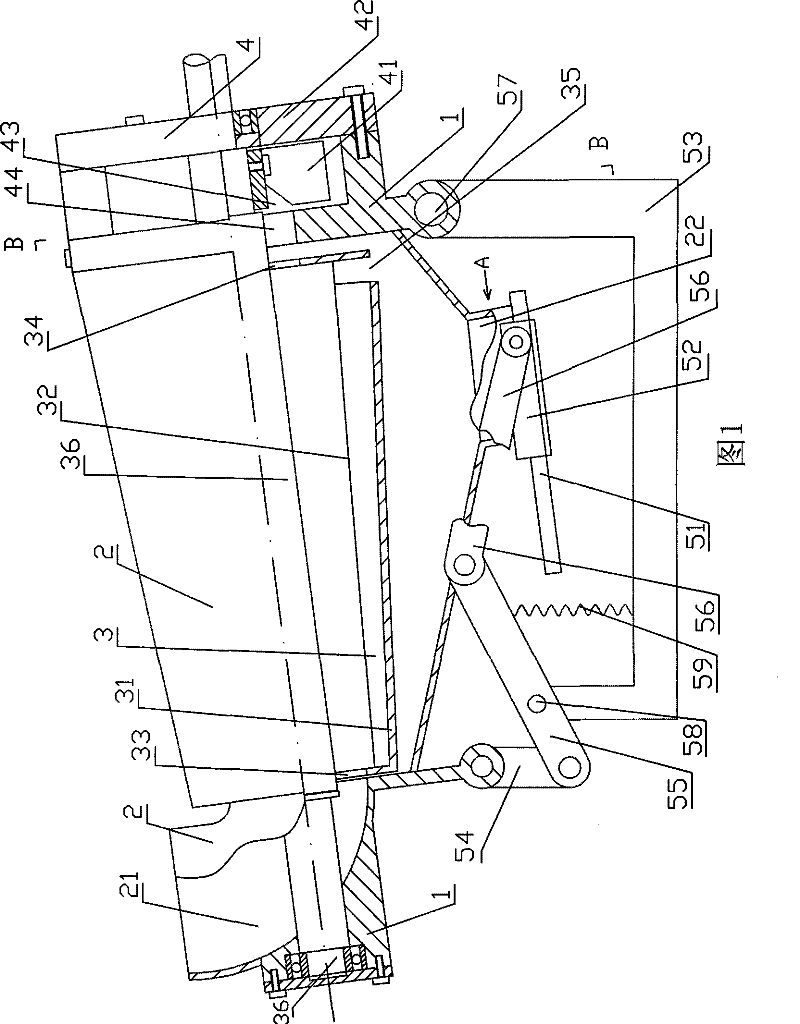

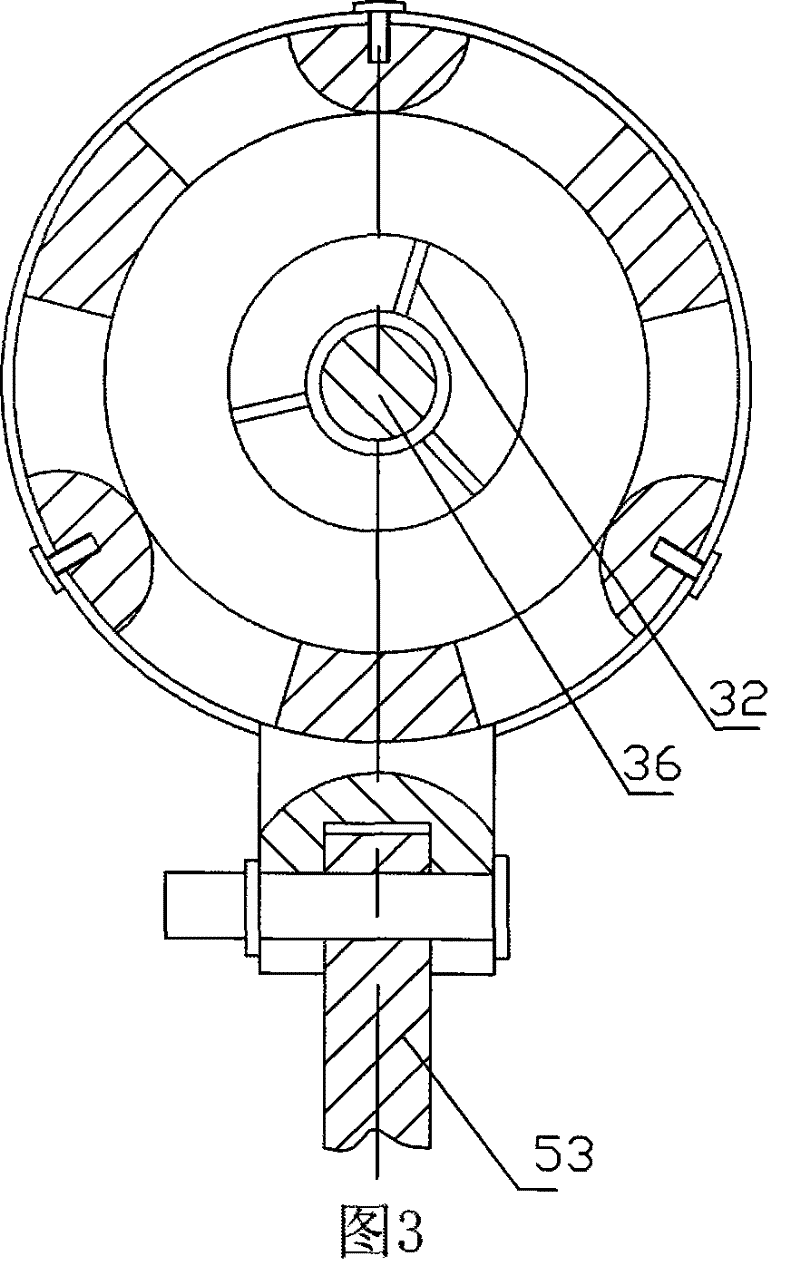

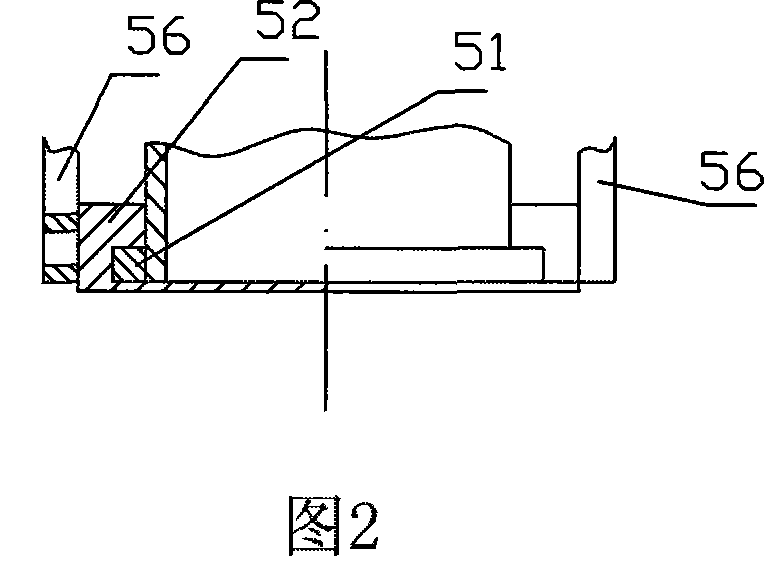

[0026] as attached Figure 1-5 Shown: gas and solid powder mixture separator, which includes frame 1, casing 2, mixture separation rotor 3, fan 4 and powder mixture discharge device; casing 2 is installed on the upper position of frame 1, on which is provided 21, the lower part of the shell 2 is provided with a discharge port 22; the mixture separation rotor 3 includes a rotor shell 31, a sleeve 37 and more than three partitions 32, the inner cavity of the rotor shell 31 is a truncated cone, and the truncated cavity The radius R1 on the left is smaller than (or equal to) the radius R2 on the right, and the sleeve 37 is fixedly installed in the truncated conical cavity of the rotor housing 31 through the partition 32, and the central axis of the sleeve 37 is located in the truncated conical cavity of the rotor housing 31 On the central axis of the cavity, the partition plate 32 divides the cavity between the rotor housing 31 and the sleeve 37 into three or more isolated cavitie...

Embodiment 2

[0030] as attached Figure 6 Shown: gas and solid powder mixture separator, which includes frame 1, casing 2, mixture separation rotor 3, fan 4 and powder mixture discharge device; powder mixture discharge device includes valve and sliding mechanism; sliding mechanism includes T T-shaped lever 60, connecting rod 61 and valve sleeve 62, T-shaped lever 60 is movably installed on the discharge port 22 of shell 2 through rotating shaft 63, T-shaped lever 60 can swing along rotating shaft 63, T-shaped lever 60 left branch end is installed with balance The weight 64, the lower branch end of the T-shaped lever 60 has a slot 65, the valve sleeve 62 is movably installed on the discharge port 22 of the casing 2, and is also movably connected with the right branch end of the T-shaped lever 60 through the connecting rod 61, the valve sleeve 62 can slide up and down along the discharge port; the valve includes a sliding baffle 67 and two slide rails 66, the two slide rails 66 are fixedly i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com