Aluminium plant electrolytic carbon residual anode surface pellet injecting and sandblast cleaning system and method

A sandblasting and shot peening technology, applied in abrasive jet machine tools, abrasives, metal processing equipment, etc., can solve the problem of poor overall noise effect of dust collector dust removal efficiency equipment, inconvenient adjustment of the position of the throwing head, and shot sorting effect. problems such as poor maintenance, to achieve the effect of saving maintenance work and maintenance costs, low noise and high work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

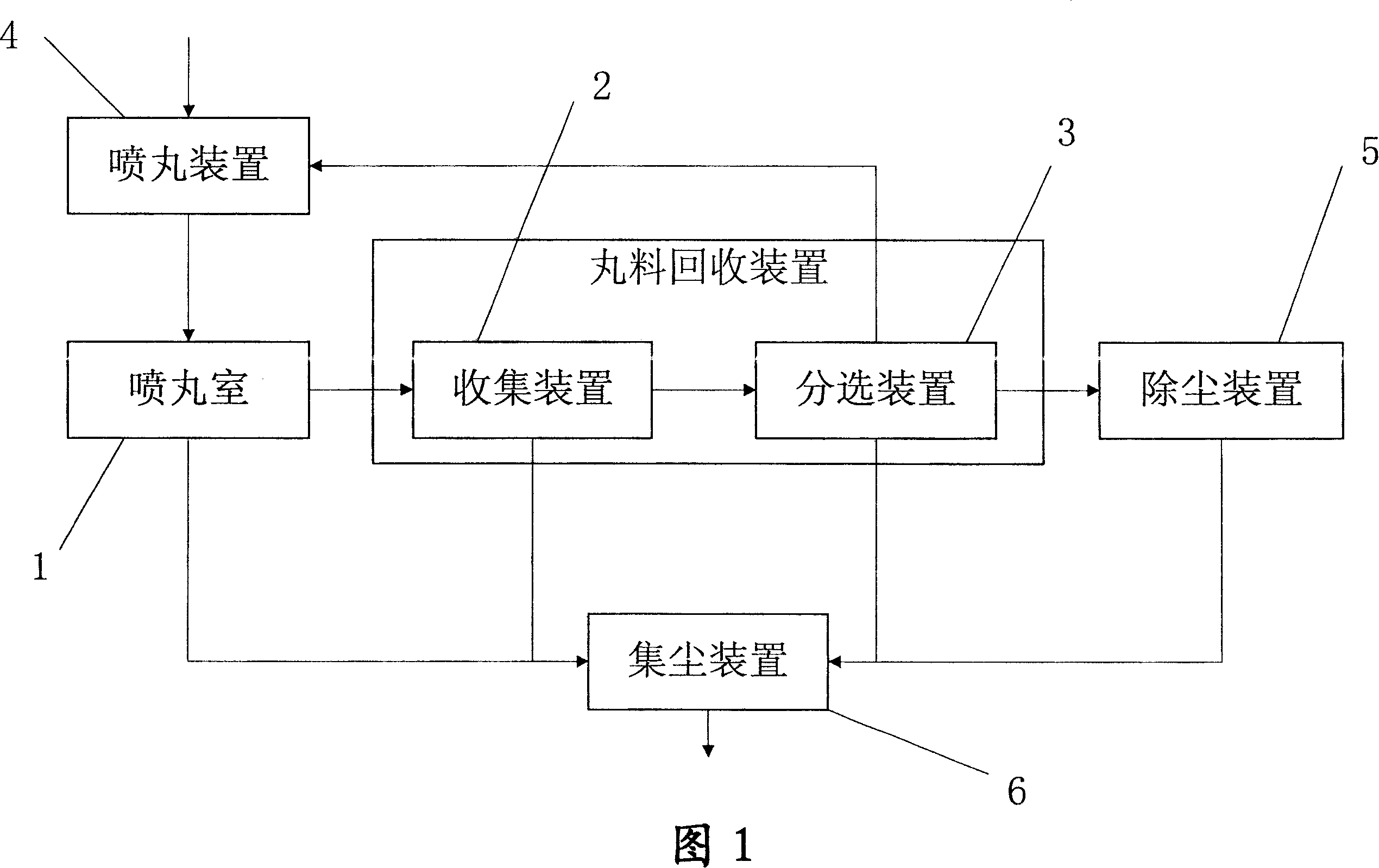

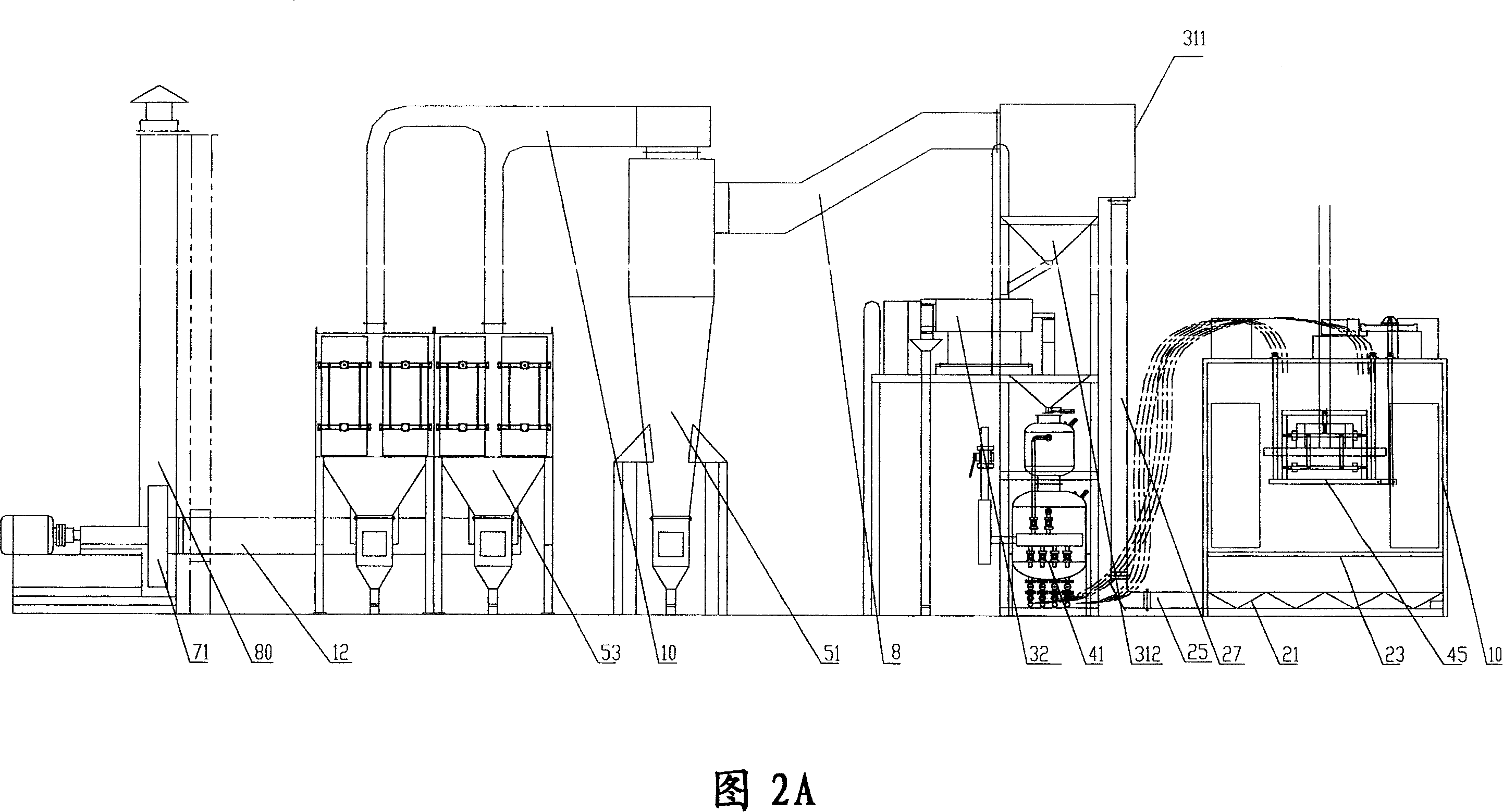

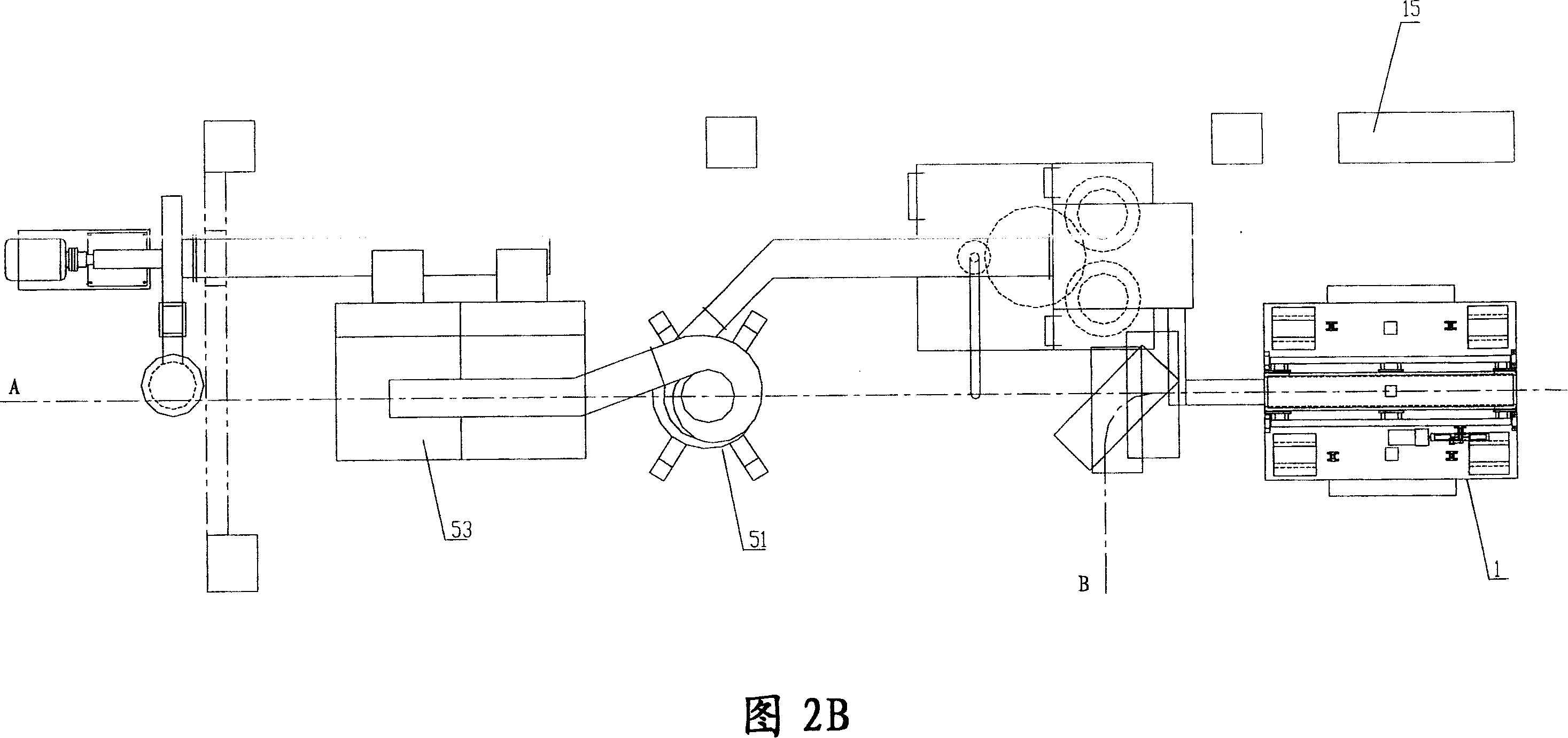

[0038] As shown in the figure, the present invention proposes a shot blasting and sandblasting cleaning system for the surface of the electrolytic carbon residual electrode in an aluminum factory. Confined space, and carry out sandblasting or shot blasting treatment to electrolytic carbon residual pole 100 in this closed space; Sandblasting or shot blasting device 4, described shot blasting device 4 comprises automatic continuous shot blasting device 41 and automatic shot blasting mechanism 45. The shot blaster is a pressure vessel for automatically storing shot materials and shot blasting. The automatic shot blasting mechanism is a plurality of spray guns installed in the shot blasting chamber. To respectively align the bottom and top of the butt workpiece 100 to carry out the shot blasting cleaning operation, to remove the impurities on the outer surface of the electrolytic carbon anode residue 100; Chain and waste conveying device for conveying waste; shot recovery device t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com