Continuous cracking method for dimethyl polysiloxane with end sealed by hydroxyl group and rectifying method for the same to preparing cyclosiloxane

A technology of polydimethylsiloxane and octamethylcyclotetrasiloxane, which is applied in the field of continuous cracking and rectification to prepare cyclosiloxane, which can solve the problems of environmental pollution and solvent treatment difficulties, and achieve the improvement of cyclosiloxane Yield and product quality, and the effect of solving solvent handling problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

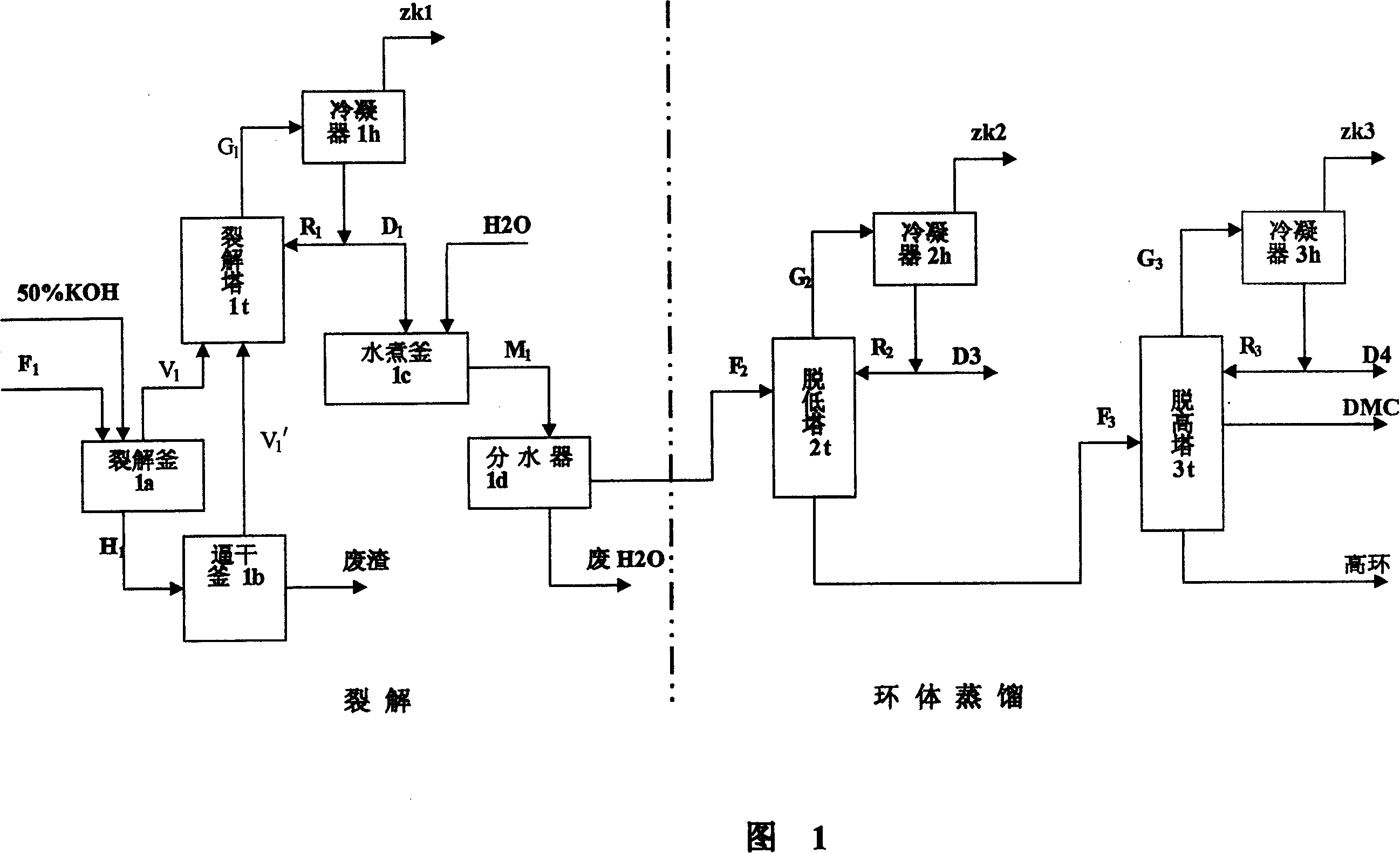

[0023] Hydroxyl-terminated polydimethylsiloxane hydrolyzate F1=2644kg / h, composition (wt): MM: 0.06%, D3: 0.5%, D4: 50%, D5: 10%, D6: 2.14%, line body : 37.3% and alkali catalyst (50% KOH aqueous solution), by the KOH aqueous solution of proportioning R=50%: hydroxyl-terminated polydimethylsiloxane hydrolyzate F1 (wt)=1: 100, continuous to cracking kettle 1a Feed, control the reaction temperature of the cracking tank to 135°C, and the reaction pressure to 0.005MPa-A. The vapor phase V1 of the mixture obtained by cracking enters the cracking tower 1t with a pressure of 0.002MPa-A and a temperature of 95°C at the top of the cracking tank from the cracking tank 1a, and cracks The tower 1t is a plate tower, and the vapor-liquid exchange is carried out with the reflux liquid on the tray, and the line body returns to the cracking kettle 1a for re-cracking, and the mixed ring body G1 mainly composed of octamethylcyclotetrasiloxane obtained at the top of the tower is condensed After c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com