Method for preparing liquid crystal thin film material with controllable reflection bandwidth

A technology of liquid crystal film and wide bandwidth, applied in liquid crystal materials, chemical instruments and methods, optics, etc., can solve problems such as difficult process control and complicated equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

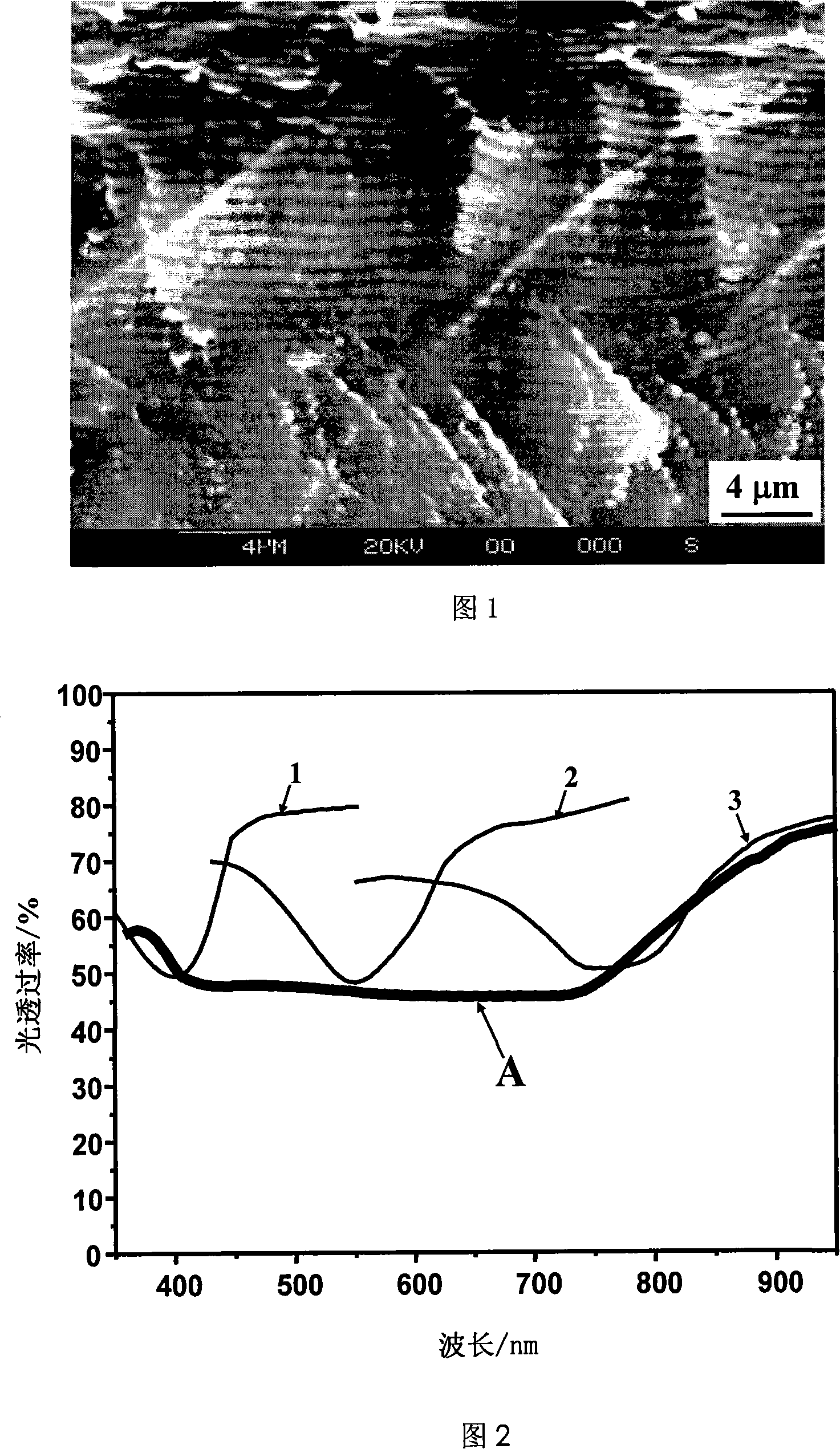

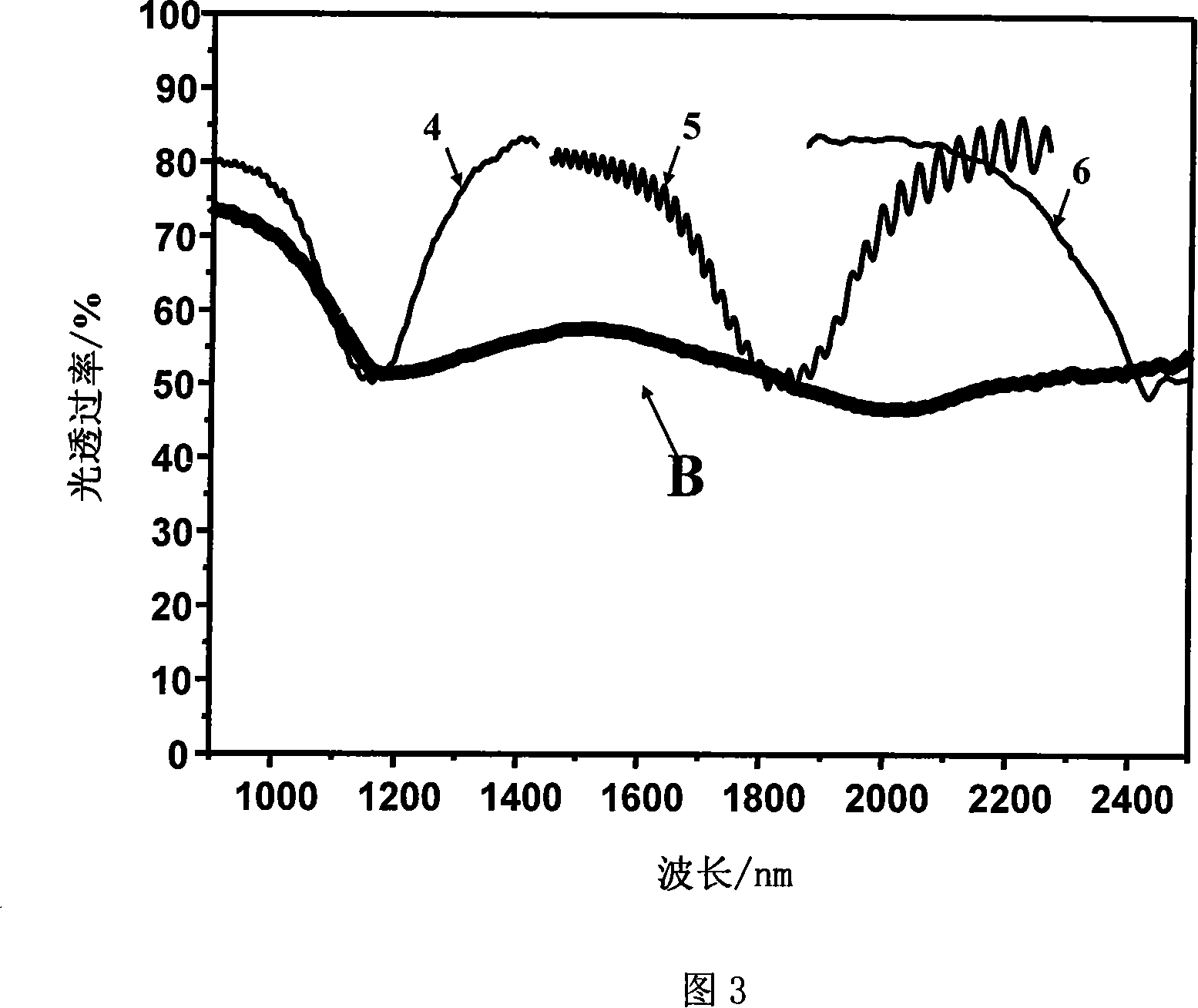

[0083] Use photopolymerizable nematic liquid crystal monomer C6M, its molecular formula is as shown in photopolymerizable liquid crystal monomer (4), and the chiral compound is ZLI-4572 of Merck Company, and its molecular formula is as shown in chiral compound (20), Photoinitiator is the Irgacure 651 of TCI company, and its molecular formula is as shown in photoinitiator (25), is dissolved in acetone in different proportions, and wherein, photoinitiator Irgacure 651 accounts for 0.5% of gross weight; No. 1, 2, 3 The weight percentages of the components C6M / ZLI4572 corresponding to the curves are 87.8 / 12.2, 91.0 / 9.0, 93.7 / 12.2 respectively. Ultrasonic vibration makes the mixture evenly mixed. Under the condition of avoiding light, the solvent is vacuumed and evaporated, and the mixture is precipitated in a solid state. It is ground into a powder with a particle size of less than 3 μm for use. To prepare a thin film with a reflection wavelength of 400-800nm, powders with a singl...

Embodiment 2

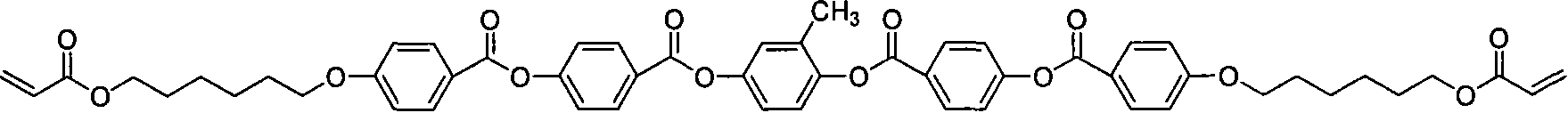

[0085]Use photopolymerizable nematic liquid crystal monomer C6M, its molecular formula is as shown in photopolymerizable liquid crystal monomer (4), and the chiral compound is ZLI-4572 of Merck Company, and its molecular formula is as shown in chiral compound (20), Photoinitiator is the Irgacure 651 of TCI company, and its molecular formula is as shown in photoinitiator (25), is dissolved in acetone in different proportions, and wherein, photoinitiator Irgacure 651 accounts for 0.5% of gross weight, No. 4, 5, 6 The weight percentages of the components C6M / ZLI4572 corresponding to the curves are 96.6 / 3.4, 97.4 / 2.6, 98.1 / 1.9 respectively. Ultrasonic vibration makes the mixture evenly mixed. Under the condition of avoiding light, the solvent is vacuumed and evaporated, and the mixture is precipitated in a solid state. It is ground into a powder with a particle size of less than 3 μm for use. To prepare a thin film with a reflection wavelength width of 1100-2500nm, powders with a ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| phase transition temperature | aaaaa | aaaaa |

| phase transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com