Self-generated nitrogen blowing and cleaning system for protective fuel battery car engine

A technology of automobile engine and fuel cell, applied in the field of purging system, can solve problems such as inconvenience of use, and achieve the effect of reducing cost, high efficiency and easy to master

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

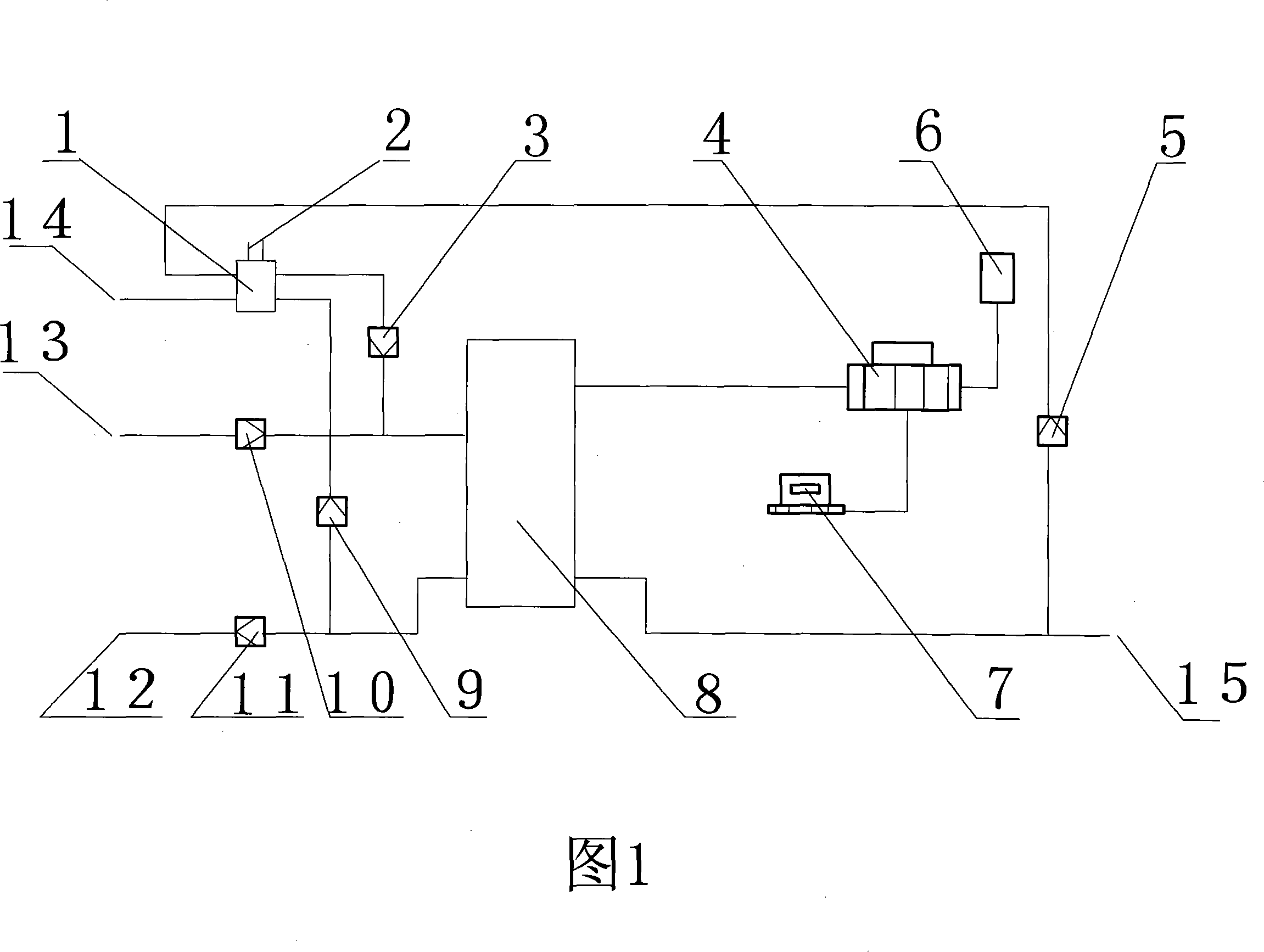

[0020] The present invention will be further described below in conjunction with the embodiments of the accompanying drawings.

[0021] The deoxidizer regeneration inlet of air deoxygenation tank 1 is connected to the hydrogen exhaust part through the regeneration control valve 9, and the regeneration control valve 9 is connected to the front end of hydrogen exhaust valve 11. The air inlet of air deoxidation tank 1 is connected to the air exhaust part 15 The channel is connected through the air control valve 5, the nitrogen outlet of the air deoxidation tank is connected with the hydrogen inlet of the fuel cell 8 through the purge control valve 3, the terminal of the electric heating and temperature control device for heating the deoxidizer in the air deoxidation tank 2 and the output of the fuel cell 8 are connected by wires.

[0022] The working procedure of present embodiment purging is as follows:

[0023] When the fuel cell stops working, open the air control valve, so t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com