Technique for industrialized development and utilization of red mud

A process method and technology of red mud, applied in chemical instruments and methods, magnetic separation, solid separation, etc., can solve the problem of using red mud to extract iron minerals that has not been done in industrial experiments and has not formed a large scale. Industrial application and other issues, to achieve the effect of increasing molten iron output, low cost, and low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] For the industrial slag liquid (red mud slurry) discharged after the extraction of alumina by the Bayer method, after the red mud settles in the tank, it is transported to the red mud yard by pipeline, and the red mud slurry L / S (the weight of the liquid and solid in the mixture Ratio) is about 2.0; temperature is about 60°C.

[0021] The main components of red mud are about:

[0022] TFe: 25.8%; FeO: 0.16%; Al 2 o 3 : 18.32%; SiO 2 : 17.8%; CaO: 2.65%; MgO: 0.16%; S: 0.16%; P: 0.11%; 2 O: 5.76%; K 2 O: 0.296%.

[0023] The iron composition in red mud is basically Fe 2 o 3 It exists in the form of hematite; but due to strong alkali and high temperature production process, there are complex Si, Fe and Al compounds in red mud.

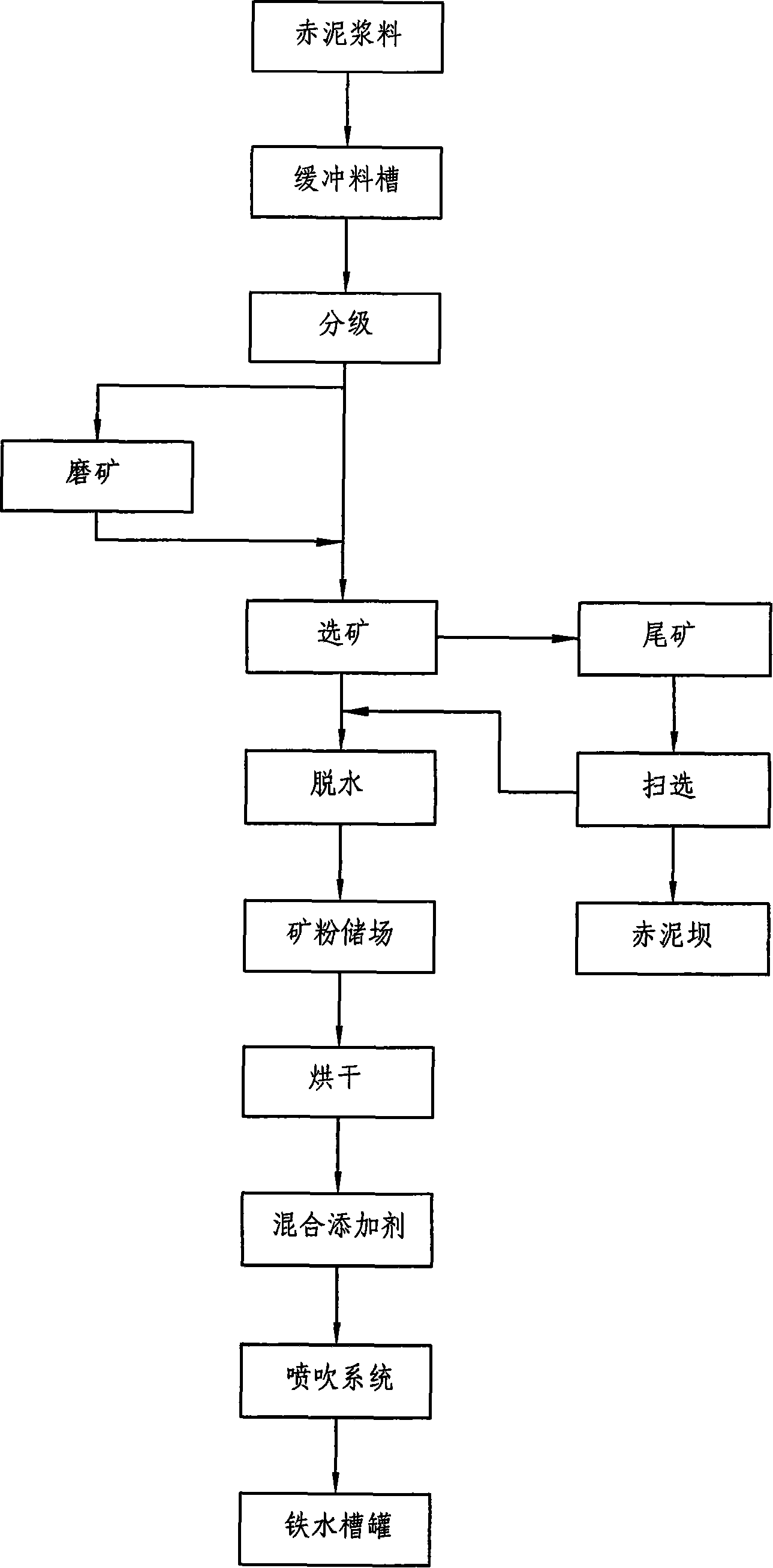

[0024] In the case of no sintering and reduction, a purely physical method (through classification, grinding, separation and enrichment, etc.) is used to select the technological process, and the whole iron is selected without secondary po...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com