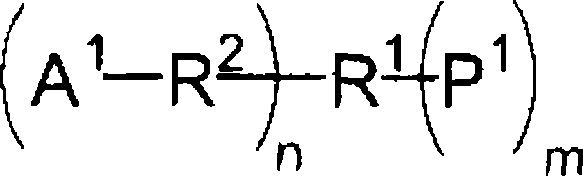

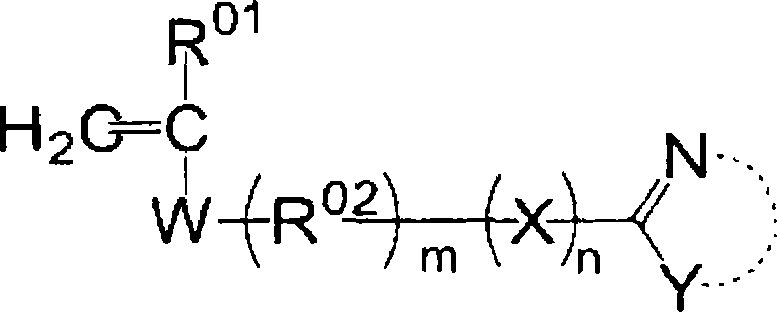

Curing colouration composition, color filtering device and liquid crystal display using the color filtering device

A coloring composition, a curable technology, applied in photosensitive materials, instruments, nonlinear optics, etc. for optomechanical equipment, which can solve problems such as performance degradation, insufficient pigment dispersion, and clogging of inkjet nozzles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0561] -Preparation of curable coloring composition-

[0562] The curable coloring composition of the present invention is prepared by mixing a colorant, the acrylic copolymer (alkali-soluble resin) of the present invention, a polymerizable compound, a photopolymerization initiator, and other components used as necessary (preferably together with a solvent), and using Prepared by mixing and dispersing with various mixers or dispersers.

[0563] In addition, the step of mixing and dispersing (mixing and dispersing step) is preferably constituted by kneading and dispersing followed by fine dispersion treatment, and kneading and dispersing may be omitted. In addition, it is preferable that the particle size of the pigment used in the kneading and dispersing steps is made finer by a common salt kneading method or the like. The method of kneading salt is known in Japanese Patent No. 3130217, Japanese Patent Application Publication No. 2003-504480, and the like. In addition, fine-...

Embodiment 1

[0602]

[0603] "1. Preparation of red curable composition"

[0604] The following red composition A was stirred using a homogenizer at 3000 rpm for 1 hour. The resulting mixed solution was subjected to microdispersion treatment for 4 hours using a bead disperser (trade name: Dispermatt, manufactured by Getzmann) using 0.3 mm zirconia beads to obtain a dispersion. In addition, the average particle diameter of a pigment is measured by the usual method by SEM observation.

[0605] - Red Composition A - Dispersion

[0606] Pigment: Pigment Red 254 (average particle size 20nm) 11 parts

[0607] Pigment: Pigment Red 177 (average particle size 18nm) 4 parts

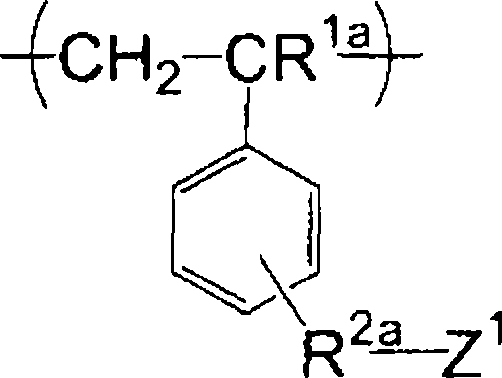

[0608] · Dispersion resin (B-1-3) (structure below) 5 parts

[0609] ・Dispersant (trade name: Disperbyk-161, manufactured by Bicchem Co., Ltd.) 3 parts

[0610] Mixed solvent of methoxybutyl acetate and butyl acetate 3 parts

[0611] Alkali-soluble resin: benzyl methacrylate / methacrylic acid copolymer=75 / 25 [mass ratio]...

Embodiment 2

[0631] "Preparation of Green Curable Composition"

[0632] A dispersion was obtained by replacing the red composition A of Example 1 with the following green composition A.

[0633] -Green Composition A-Dispersion

[0634] Pigment: Pigment Green 36 (average particle size 19nm) 11 parts

[0635] Pigment: Pigment Yellow 150 (average particle size 22nm) 7 parts

[0636] · Dispersion resin (B-1-26) (structure below) 5 parts

[0637] ・Dispersant (trade name: Disperbyk-161, manufactured by Bicchem Co., Ltd., 30%

[0638] 3 parts solution)

[0639] Alkali-soluble resin: benzyl methacrylate / methacrylic acid copolymer

[0640] 4 parts = 75 / 25 [mass ratio] copolymer, propylene glycol monomethyl ether acetate solution (solid content: 50% by mass) with a weight molecular weight Mw: 5000

[0641] ・(B) Solvent for Dispersion Resin Dissolving: 3-ethoxymethyl propionate ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Boiling point | aaaaa | aaaaa |

| Boiling point | aaaaa | aaaaa |

| Boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com