Microwave sintering method for thermal resistor with positive temperature coefficient and its special device

A positive temperature coefficient and thermistor technology, which is applied in the direction of resistors with positive temperature coefficients, resistors, resistance manufacturing, etc., can solve the problems of few applications, achieve low sintering temperature, high energy utilization rate, and short constant temperature time Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

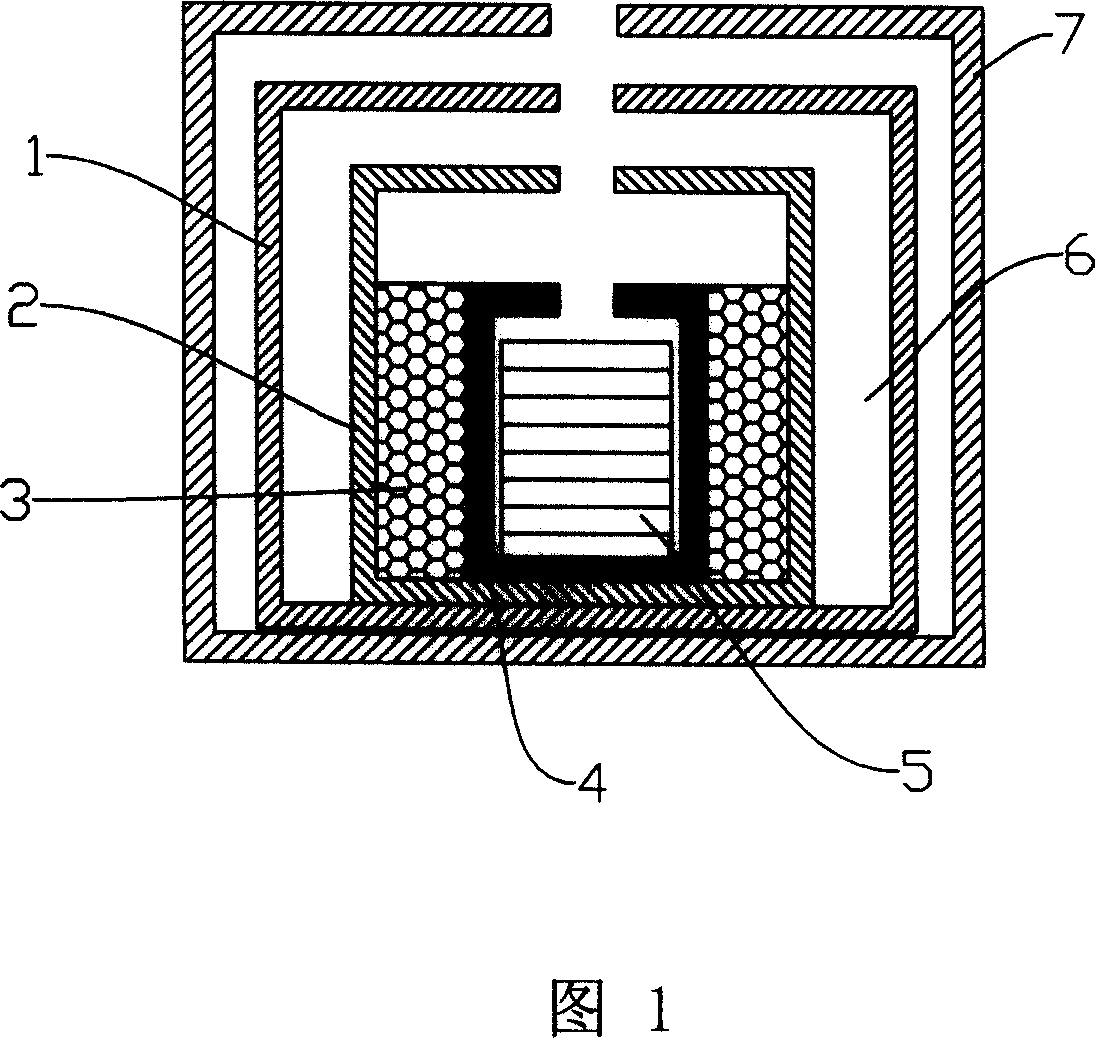

[0017] First, prepare the special equipment used in the present invention. The special equipment for the equipment, as shown in Figure 1, includes a microwave oven body 1, in which a sintering special insulation body is provided, and the sintering special insulation The body includes: an outer fiber insulation body 1, a secondary outer insulation body 2 and an inner crucible 4, and a fiber insulation ball filling layer 3 is provided between the outer insulation body 2 and the inner crucible 4; A thermal insulation space 6 is provided between the fiber thermal insulation body 1 of the outer layer and the thermal insulation body 2 of the secondary outer layer. In this embodiment, the fiber insulation 1 of the outer layer is Al 2 O 3 Material production; the second outer layer insulation body 2 is MgAl 2 O 4 -LaCrO 3 Material production, the inner crucible 4 is Al 2 O 3 Corundum crucible made of materials; the fiber insulation ball is Al 2 O 3 Fiber insulation ball. The outer fiber i...

Embodiment 2

[0020] Put ceramic green body 5 into Al 2 O 3 Corundum crucible, and then filled with the green Al 2 O 3 Corundum crucible, Al 2 O 3 Fiber insulation ball 3, MgAl 2 O 4 -LaCrO 3 Insulation body 2, Al 2 O 3 The fiber insulation body 1 is put into a 2.45GHz multi-mode reaction cavity microwave oven sintering device, and sintered at a power lower than 6.0KW. The microwave power is 1.2KW in the temperature range from room temperature to 400°C, and the heating rate is 15°C / min , The heating rate is 10℃ / min in the temperature zone of 400℃~1150℃, the temperature is kept constant at 1200℃ for 20 minutes, and then the temperature is reduced to 500℃ at 10℃ / min, and then the microwave source is turned off and cooled naturally. Barium titanate series positive temperature coefficient thermistor ceramics. The outer fiber insulation body 1 is a cylindrical structure with upper and lower cover plates; the corundum crucible 4 is a cylindrical structure with upper and lower cover plates.

[0021] T...

Embodiment 3

[0023] Put ceramic green body 5 into Al 2 O 3 Corundum crucible 4, and then fill the Al 2 O 3 Corundum crucible, Al 2 O 3 Fiber insulation ball 3, MgAl 2 O 4 -LaCrO 3 Insulation body 2, Al 2 O 3 The fiber insulation body 1 is put into a 2.45GHz multi-mode reaction cavity microwave sintering device, and sintered at a power lower than 6.0KW. The microwave power is 1.5KW in the temperature range from room temperature to 400°C, and the heating rate is 18°C / min. , In the temperature zone of 400℃~1150℃, the heating rate is 20℃ / min, at 1250℃, constant temperature for 15 minutes, and then the temperature is reduced to 500℃ at 10℃ / min, and then the microwave source is turned off and cooled naturally to obtain a uniform and compact without cracking Barium titanate series positive temperature coefficient thermistor ceramics.

[0024] The other parts of this embodiment are completely the same as the first embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com