Fermented protein product

A fermented product and protein technology, which is applied to the protein composition of yeast, protein food ingredients, protein food processing, etc., can solve problems such as improvement of flavor that is not mentioned

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

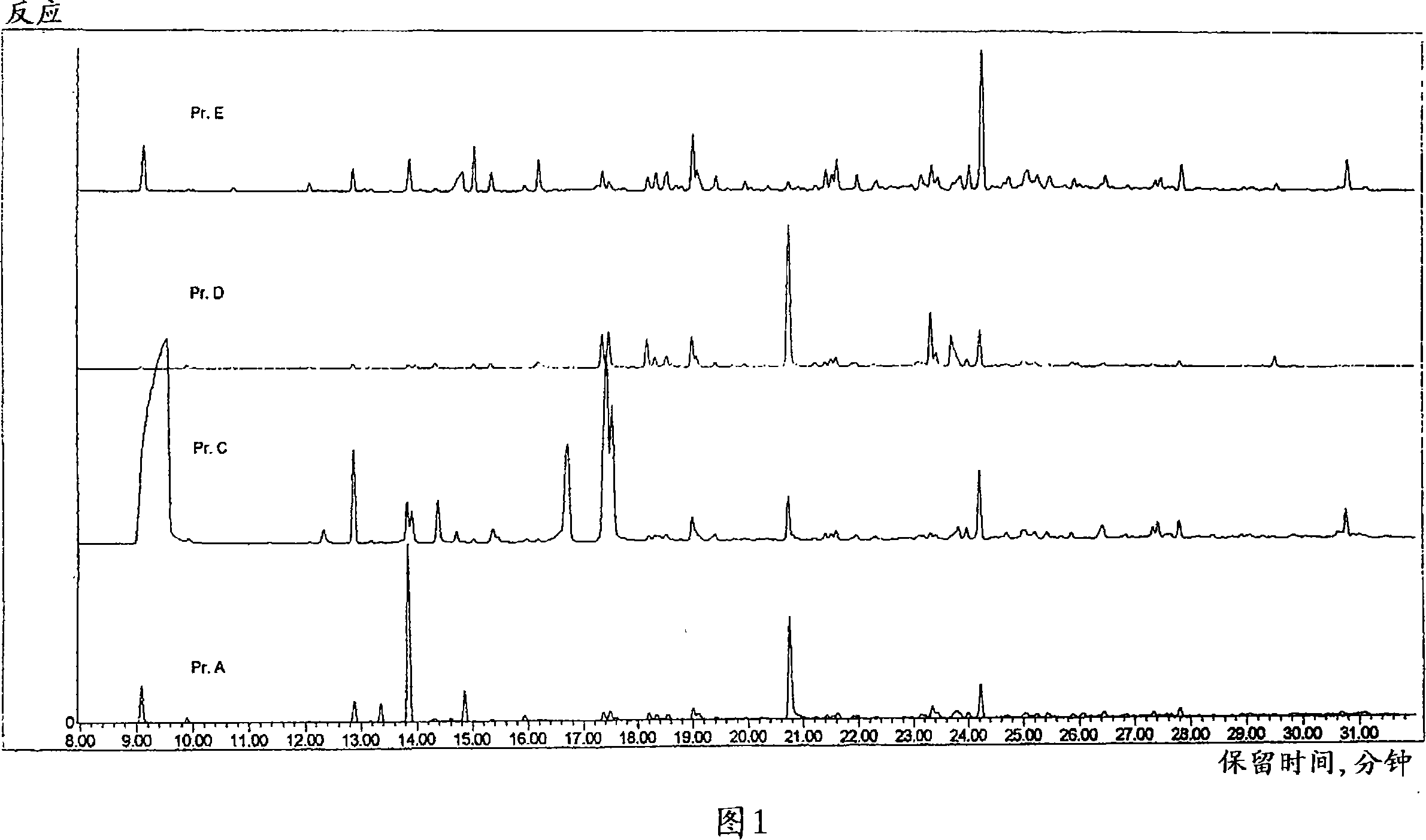

Image

Examples

Embodiment 1

[0122] Production and composition of defatted soybean-based fermented products

[0123] 50.0 kg of dehulled and defatted flash desolventised soybean flakes were moistened with 10.0 kg of tap water and extruded at 150°C on a Werner Pfleiderer pilot extruder. After cooling to 50°C, 60.0 kg of centrifuged spent brewer's yeast (containing about 10% dry matter) and 50 g of phytase (BASF Natuphos 5000L) were added. The resulting slurry was mixed and incubated anaerobically at 33°C for 5 hours. Next, a second incubation was performed at 85°C for 40 minutes in a closed system. Subsequently, the product is rapidly dried under such conditions that the particle temperature does not exceed 85° C., and ground on an Alpine pin mill.

[0124] The dried product has the following analytical data:

[0125] Crude protein (N×6, 25) 58.3%

[0126] Humidity 5.2%

[0127] Crude Fat 0.9%

[0128] Crude Fiber 4.2%

[0129] Phytic acid-bound phosphorus 0.05%

[0130] pH (1:10 water dispersion...

Embodiment 2

[0141] Production and composition of whole soybean based fermented products

[0142] 10.0 kg whole soybeans were dehulled, flaked and heated at 150°C in a rotary oven (Dantoaster). After cooling to 55°C, 6.0 kg of tap water, 3.0 kg of centrifuged spent brewer's yeast and 10 g of phospholipase (Lecitase from Novozymes) were mixed. The mixture was incubated anaerobically at 38°C for 4 hours and then at 92°C for 20 minutes in a closed system. After drying under vacuum at 50° C., the product was finely ground on a Bühler ball mill. The milled product forms a stable suspension in water and has a pleasant flavor and mouthfeel.

[0143] The dry product has the following composition:

[0144] Crude Protein 42.4%

[0145] Crude Fat 22.4%

[0146] Crude Fiber 3.5%

[0147] Water 4.5%

[0148] pH (1:10 water dispersion) 6.4

Embodiment 3

[0150] Production and composition of lupine-based fermented products

[0151] 200g of roasted Australian Lupine Meal were mixed with 20g of centrifuged brewer's yeast and 200ml of tap water. After 10 hours of anaerobic incubation at 36°C, a second incubation step is carried out at 100°C for 30 minutes in a closed system, drying the product in a laboratory fluidized bed dryer under such conditions that the particle temperature does not exceed 85°C, Columns were milled and analyzed as follows, compared to the starting material.

[0152] raw material

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com