Concentration method for iron and boron in low-grade paigeite

A boronite, low-grade technology, applied in chemical instruments and methods, boron/boride, solid separation, etc., can solve problems such as blast furnace lining erosion, blast furnace productivity decline, and limited application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

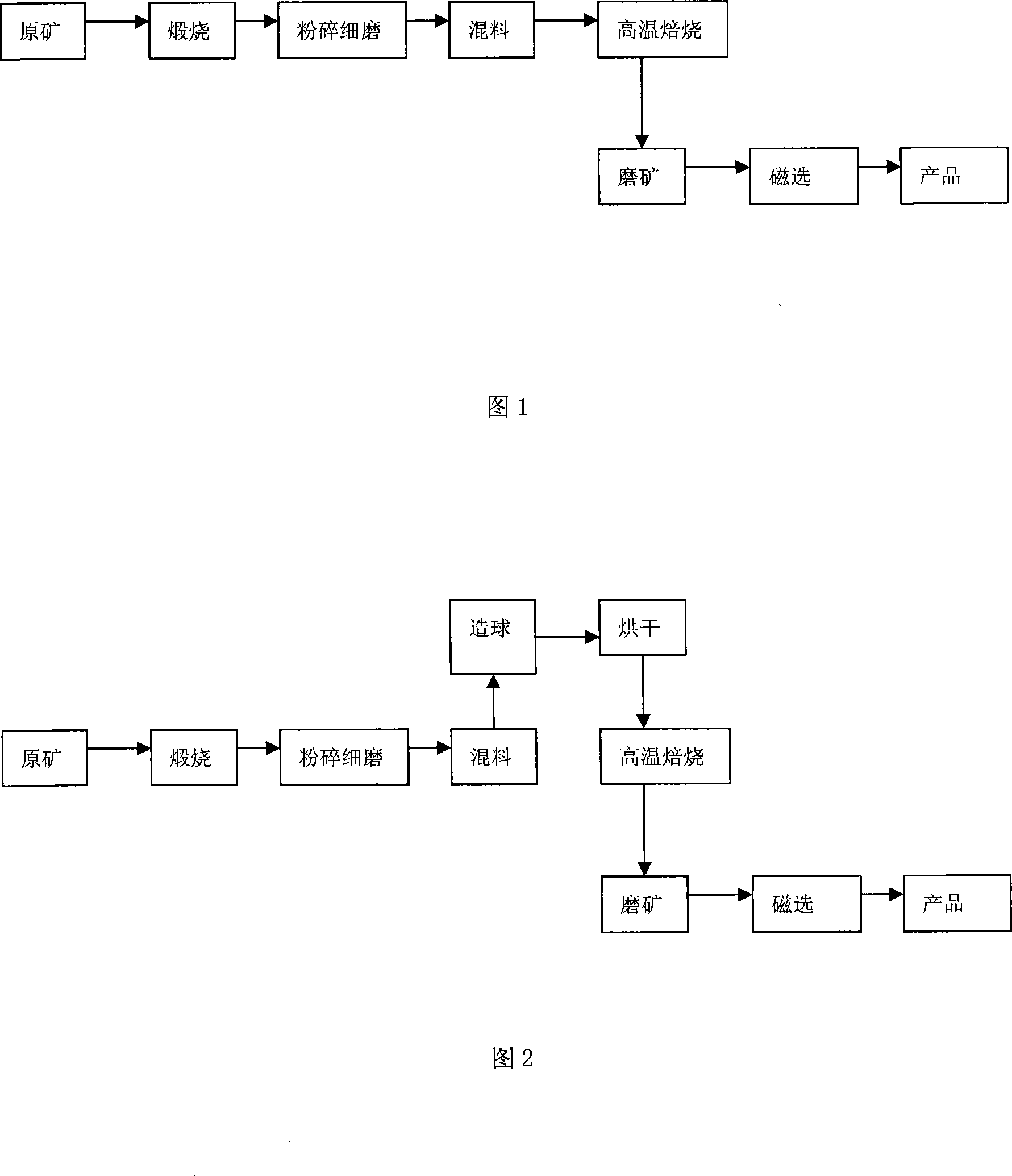

Embodiment 1

[0021] After the calcined low-grade boron ore is pulverized by a hammer mill, it is sent to a ball mill for grinding until it can pass through a 0.096mm sieve, and the coke is also ground until it can pass through a 0.096mm sieve, and 10% of the weight of the ore is added. Coke powder, Mix it on the mixer and send it to the distribution bin through the belt, and put it into the rotary hearth furnace with a material layer thickness of 2-3cm. The flow time of the mineral material in the furnace is 30 minutes, and the mineral material slowly flows through the rotary hearth The bottom furnace flows into the discharge port, and is sent to the magnetic separation plant for magnetic separation after cooling and grinding. After separation, the magnetic material is iron powder, and the non-magnetic material is boron concentrate. Its composition is shown in Table 1:

[0022] Table 1

[0023] sample number

[0024] It can be seen from the above table that with the increase of ...

Embodiment 2

[0026] After the calcined low-grade boron ore is pulverized by a hammer mill, it is sent to a ball mill for grinding until it can pass through a 0.096mm sieve, and the coke is also ground until it can pass through a 0.096mm sieve, and 10% of the weight of the ore is added. Coke powder, Mixed on the mixer and sent to the pelletizing workshop by the belt for drying of the balls. The strength of the balls is that they will not be pulverized in the rotary hearth furnace. Roasting in the hearth furnace for 20 minutes, the discharge material is cooled and then ground and then magnetically separated. The grades of iron concentrate powder and boron concentrate powder after selection are shown in Table 2:

[0027] Table 2

[0028] sample number

[0029] From the above two tables, it can be seen that the grades of iron concentrate powder and boron concentrate powder are not much different after roasting, but the roasting time is shorter than that of powder ore roasting directl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com