Method for preparing P-type transparent conductive oxide CuAlO2 film

A transparent conductive and oxide technology, used in chemical instruments and methods, circuits, electrical components, etc., can solve the problems of lack of large-scale production capacity, high production cost, and large deposition area.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

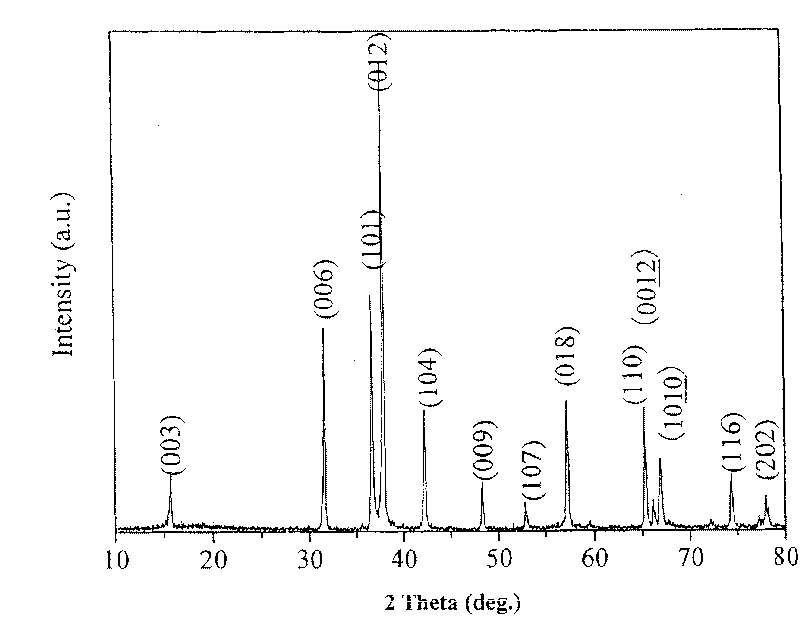

[0019] (1) With chemically pure Cu 2 O powder and analytically pure Al(OH) 3 The powder is used as the raw material, and it is pre-calcined at 500°C for 1 hour using a high-temperature solid-state reaction method, and then calcined at 1100°C for 10 hours to fully react to form pure-phase delafossite structure CuAlO 2 powder, on CuAlO 2 Powder ball milling mixed with glue and pressed into tablets, after removing the glue, sintered at 1100°C for 4h to make CuAlO 2 Ceramic target. Its XRD spectrum (see figure 1 ) is fully consistent with CuAlO 2 PDF35-1401 Diffraction Standard Spectrum.

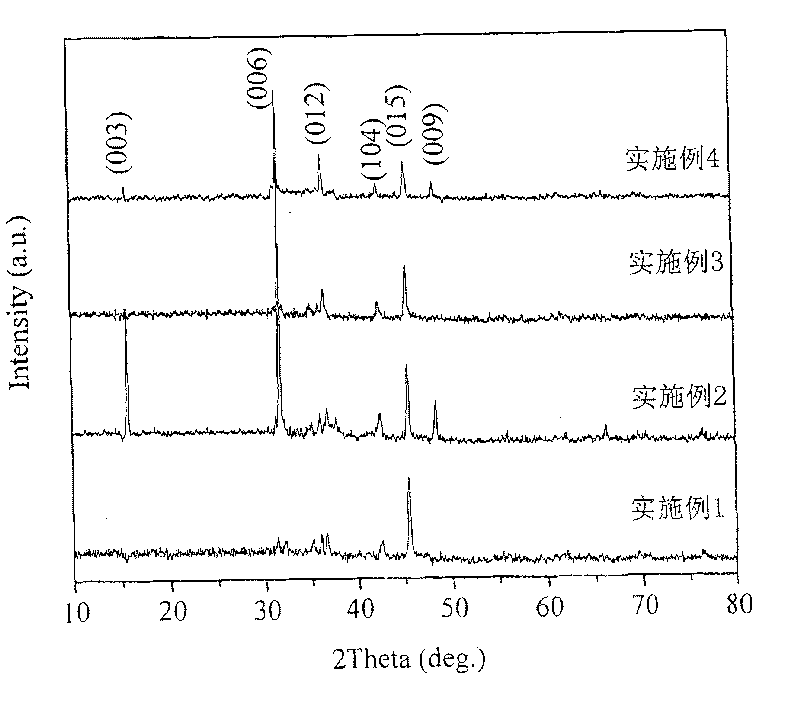

[0020] (2) Deposit CuAlO on Si(100) substrate by magnetron sputtering method 2 Thin film, the substrate temperature is 300°C, the working pressure is 0.8Pa, the oxygen partial pressure is 20%, the sputtering power is 100W, under the protection of nitrogen atmosphere, after annealing at 900°C for 2h, P-type CuAlO is obtained 2 film, its XRD spectrum is shown in figure 2 .

Embodiment 2

[0022] The substrate temperature is 400°C, the working pressure is 0.9Pa, and other preparation conditions are the same as in Example 1. The XRD spectrum of the obtained film is shown in figure 2 .

Embodiment 3

[0024] The substrate temperature is 500°C, the working pressure is 1.0Pa, annealed at a temperature of 1100°C for 4h, other preparation conditions are the same as in Example 1, and the XRD spectrum of the obtained film is shown in figure 2 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com