Precipitated calcium carbonate pigment, especially for use in inkjet printing paper coatings

An inkjet printing, inkjet technology, applied in calcium carbonate/strontium/barium, printing, nanotechnology for materials and surface science, etc., can solve problems such as preparation of paper coating pigments that are not specifically pointed out

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

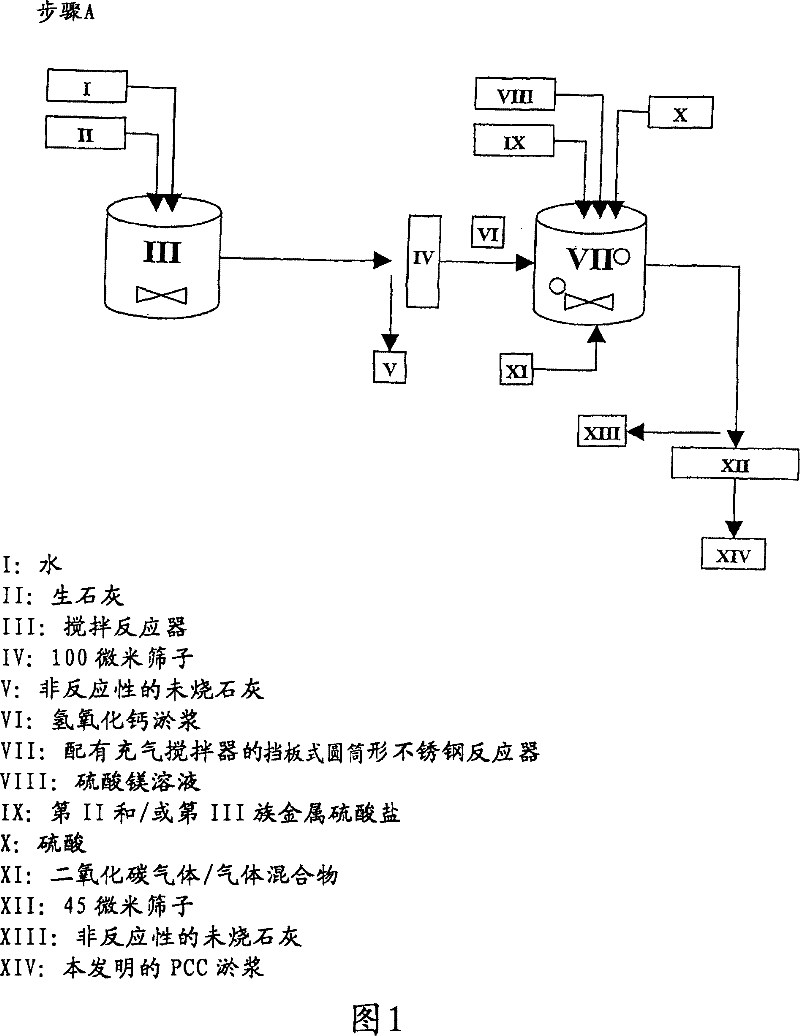

[0173] Method of the present invention, step A with magnesium sulfate and zinc sulfate:

[0174] 150 kg of quicklime were added to 1300 liters of tap water in a stirred reactor. Before the lime is added, the water temperature is adjusted to 40°C.

[0175] The quicklime was digested for 25 minutes under continuous stirring, and the resulting calcium hydroxide slurry ("milk of lime") at 13.1% w / w solids content was sieved on a 100 micron sieve.

[0176] CaCO3 precipitate is introduced into a baffled 1000 liter aerated agitator with gas dispersion unit, stainless steel carbide tubes for introducing the CO2 / air flow into the impeller and probes for monitoring the pH and conductivity of the suspension In a cylindrical stainless steel reactor.

[0177] 700 liters of the calcium hydroxide suspension obtained in the above digestion step were added to the carbonization reactor and the temperature of the reaction mixture was adjusted to the desired starting temperature of 20 °C.

...

Embodiment 2

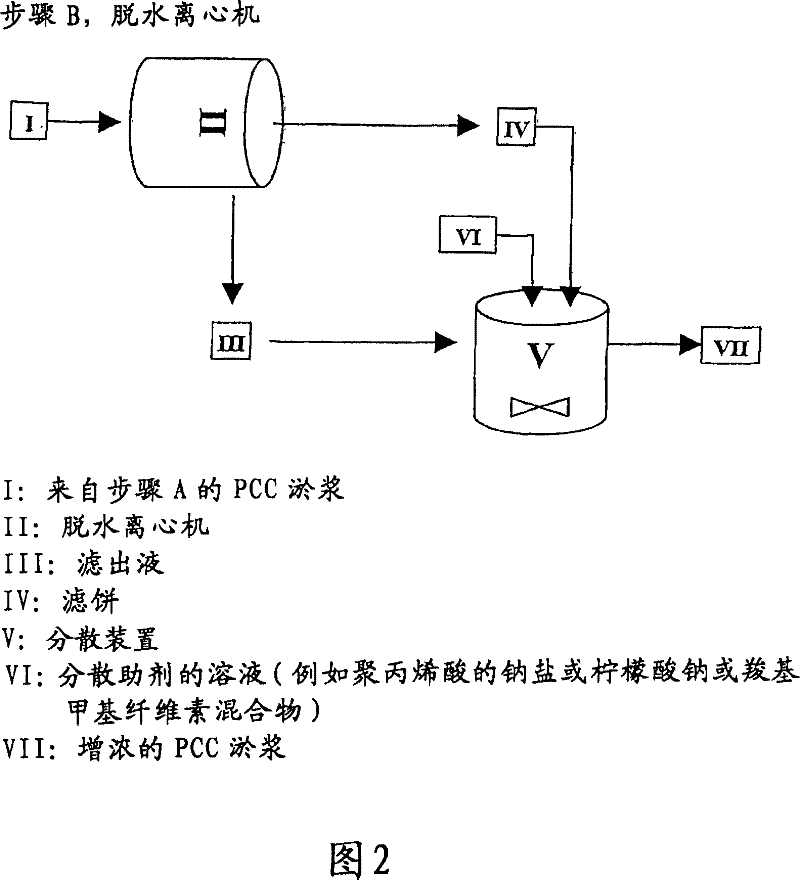

[0191] Process of the invention, enrichment of the product of Example 1 (step B):

[0192] 2210 g of precipitated calcium carbonate slurry obtained according to step A of the process as described in Example 1 was cooled to 25° C. and dewatered in step B using a pressurized filter.

[0193] A filter cake with a solids content of approximately 43% w / w was obtained.

[0194] The filtrate was collected and used for redispersion of the filter cake.

[0195] 50 g of the filtrate obtained in the dehydration step as described above was added to a 1 liter dispersing device equipped with an impeller and redispersed without using any dispersing agent.

[0196] In this mixture, the filter cake obtained in the above dehydration step with a residual moisture content of 57% w / w was gradually added to the dispersing device under continuous mixing.

[0197] After each filter cake addition and subsequent homogenization, the Brookfield viscosity of the slurry was measured at 100 rpm. Cake add...

Embodiment 3

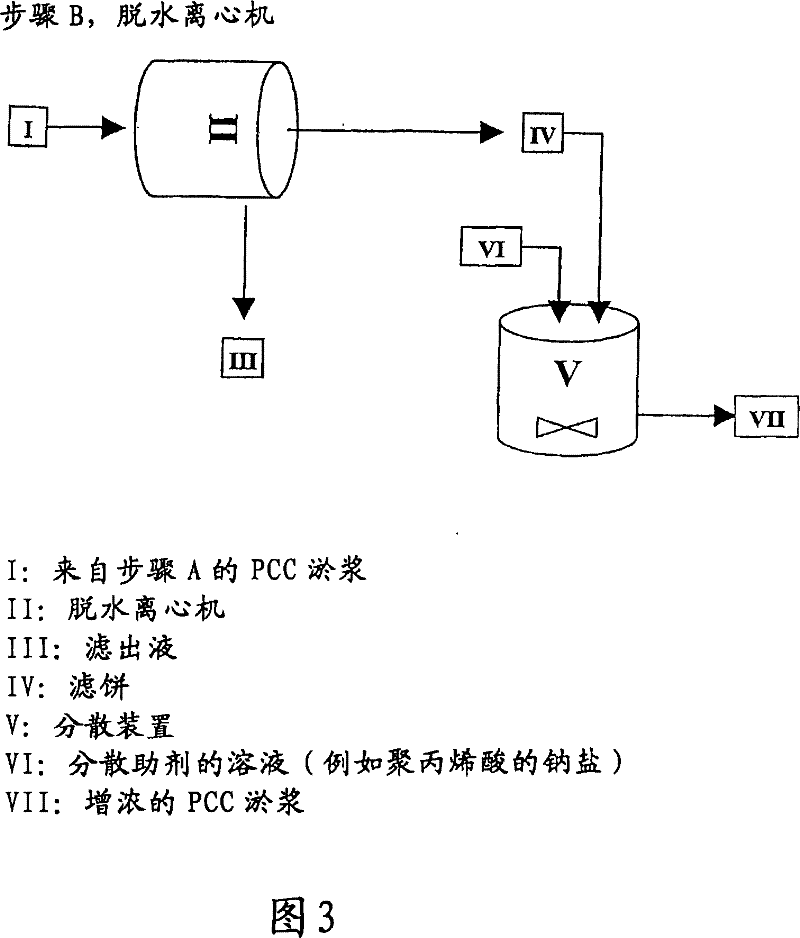

[0205] Process of the invention, enrichment of the product of Example 1 (step B):

[0206] 2210 g of precipitated calcium carbonate slurry obtained according to the method described in Example 1 was cooled to 25° C. and dewatered using a pressure filter. The filtrate was collected and used for subsequent filter cake redispersion.

[0207] 30 g of the filtrate obtained in the dehydration step as described above was added to a 1 liter dispersing device equipped with an impeller and redispersed without using any dispersing agent.

[0208] In this mixture, the filter cake obtained in the above dehydration step with a residual moisture content of 36.4% w / w was gradually added to the dispersing device under continuous mixing. After each filter cake addition and subsequent homogenization, the Brookfield viscosity of the slurry was measured at 100 rpm. Cake addition was stopped when the Brookfield viscosity reached a specified maximum of approximately 1000 mPas.

[0209] At this ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com