Oxidized plumbago of loading nanometer metallic silver corpuscle and its preparing method

A nano-metallic silver and graphite technology, applied in chemical instruments and methods, catalyst activation/preparation, metal/metal oxide/metal hydroxide catalysts, etc. The industrial application of graphite composites and other issues can achieve the effects of reducing agglomeration, increasing specific surface area, good application prospects and economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

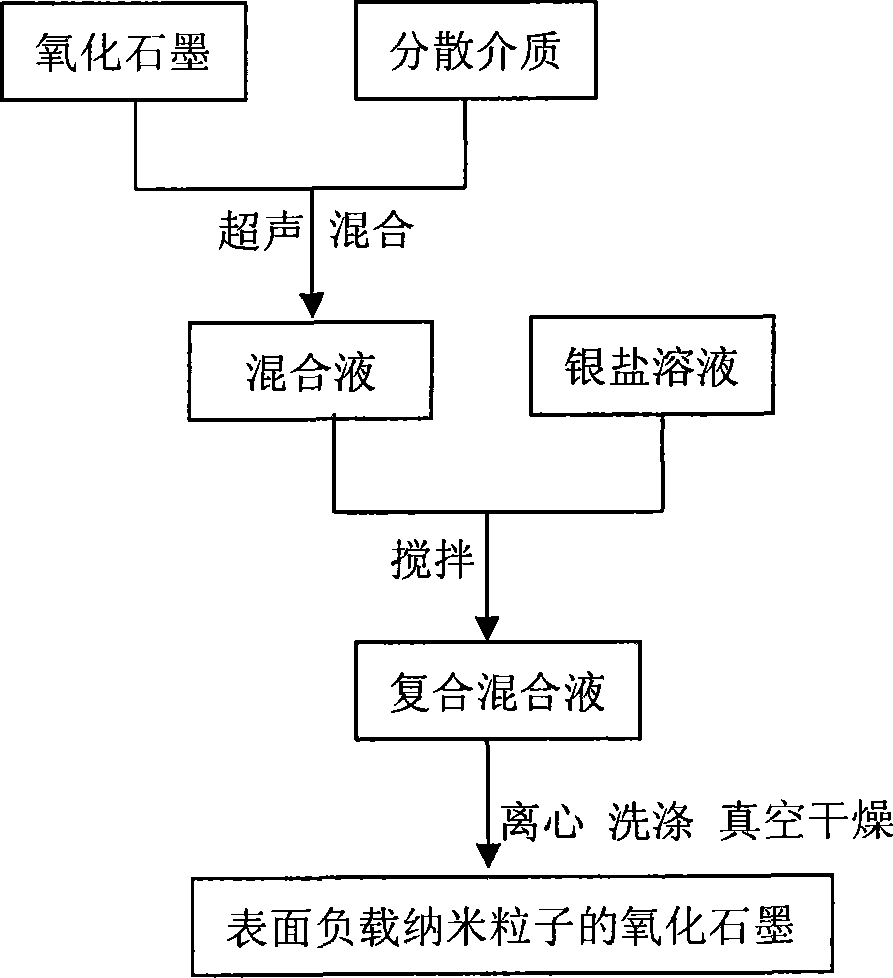

[0025] Embodiment 1: the method for the preparation of the graphite oxide of the present invention loaded nano-metallic silver particle, comprises the following steps:

[0026] The first step is the preparation of graphite oxide. Cool 460mL of concentrated sulfuric acid containing 10g of sodium nitrate to 0-5°C, then add 20g of graphite into it, then slowly add potassium permanganate so that the temperature of the system does not exceed 20°C, stir well and put in 30-35 In a water bath at ℃, after stirring for a certain period of time, slowly add 4.6L of deionized water so that the temperature of the system does not exceed 98 ℃, and then stir for 10 minutes. Add 2.8L of deionized water, and then add 50mL of hydrogen peroxide. The resulting yellow suspension was centrifuged until the filtrate was free of sulfate ions. The product was dried under vacuum at 60°C.

[0027] In the second step, ultrasonically disperse 50 mg of graphite oxide into 50 mL of N,N-dimethylformamide and...

Embodiment 2

[0031] Embodiment 2: the method for preparing the graphite oxide of the present invention loaded nano-metallic silver particle, comprises the following steps:

[0032] The first step is the same as step one in Example 1;

[0033] In the second step, ultrasonically disperse 15 mg of graphite oxide into 50 mL of N,N-dimethylformamide for 1 to 2 hours;

[0034] In the third step, add 1.5 mL of 0.05 mol / mL silver nitrate solution to the mixed solution in the second step, and stir for 0.5 to 1 hour;

[0035] In the fourth step, the mixture obtained in the third step was reacted in a dark room at 60° C. for 1 day.

[0036] The fifth step is the same as step five in Example 1.

Embodiment 3

[0037] Embodiment 3: the method for the preparation of the graphite oxide of the present invention loaded nano-metallic silver particle, comprises the following steps:

[0038] The first step is the same as step one in Example 1;

[0039] The second step is the same as step one in Example 1;

[0040] In the third step, add 0.5 mL of 0.1 mol / mL silver nitrate solution to the mixed solution in the second step, and stir for 0.5 to 1 hour;

[0041] In the fourth step, the mixed solution obtained in the third step was reacted in a dark room at 100° C. for 2 hours.

[0042] The fifth step is the same as step five in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com