Resonant vibration dead-soft switching inverter circuit applied to brushless DC motor and control method

A brushed DC motor and inverter circuit technology, applied in the direction of single motor speed/torque control, irreversible DC power input conversion to AC power output, high-efficiency power electronic conversion, etc. The motor can not work normally, increase the conduction power consumption, etc., to achieve the effect of facilitating device selection, overcoming the problem of reverse recovery, and reducing additional costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

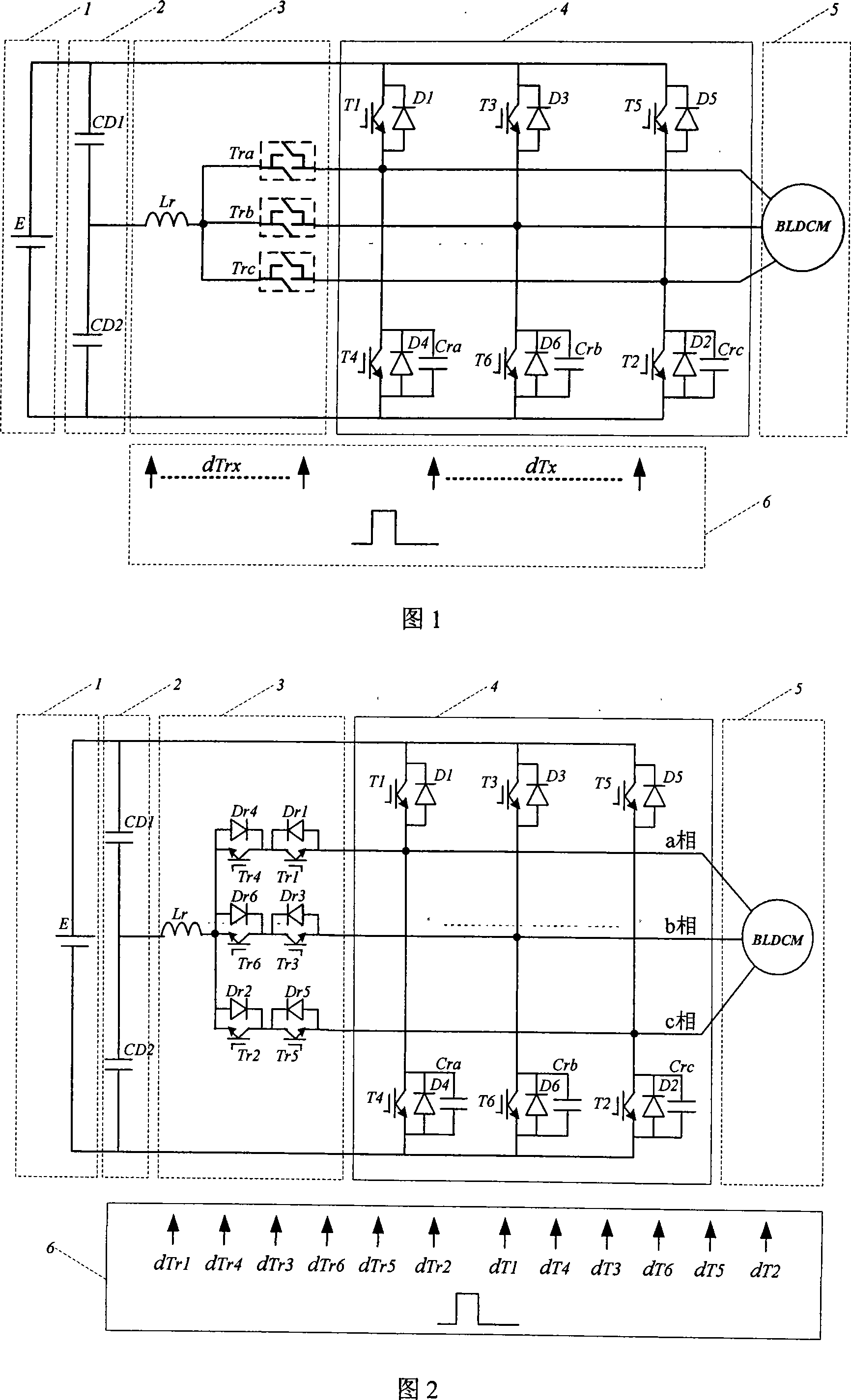

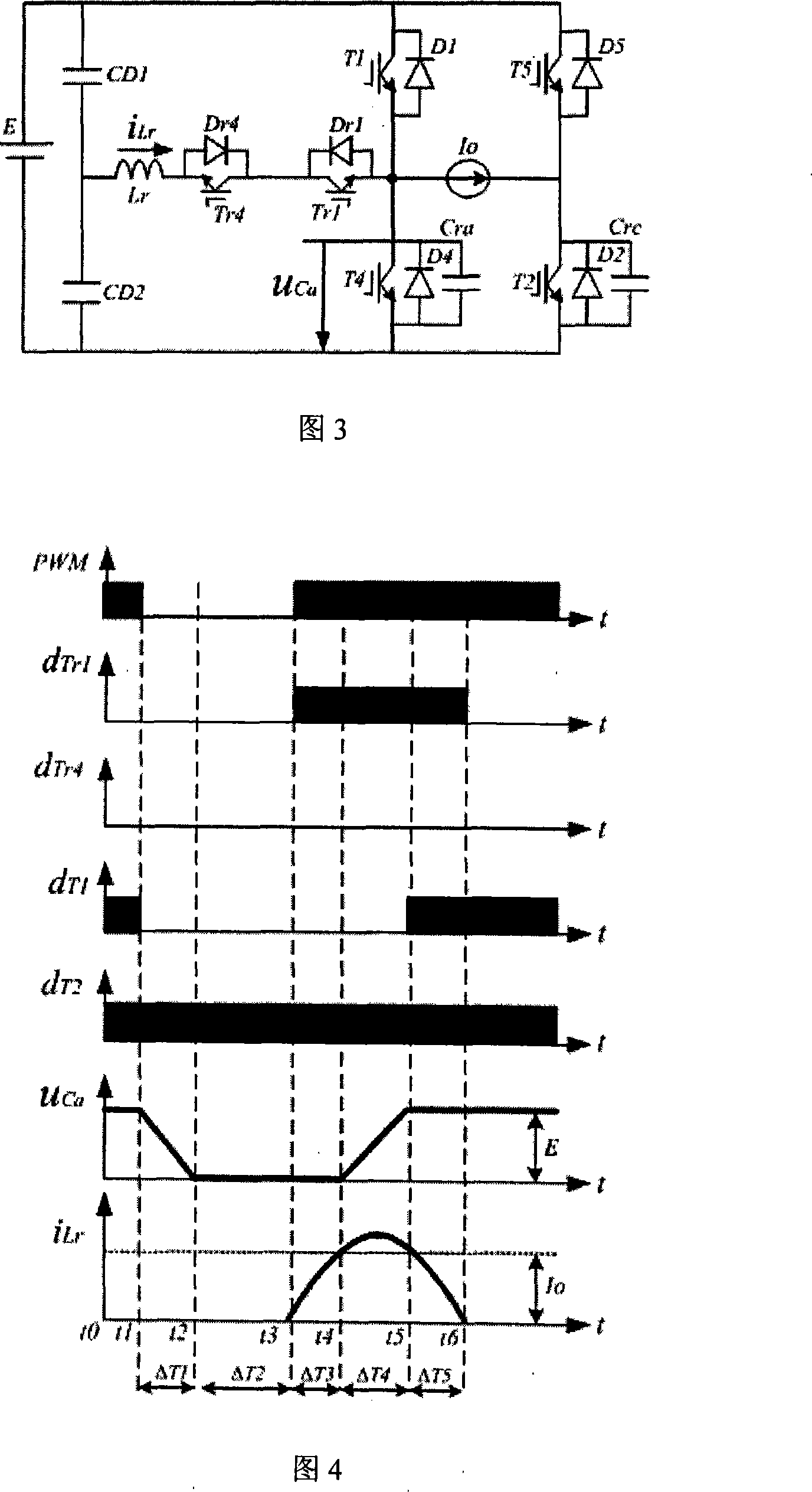

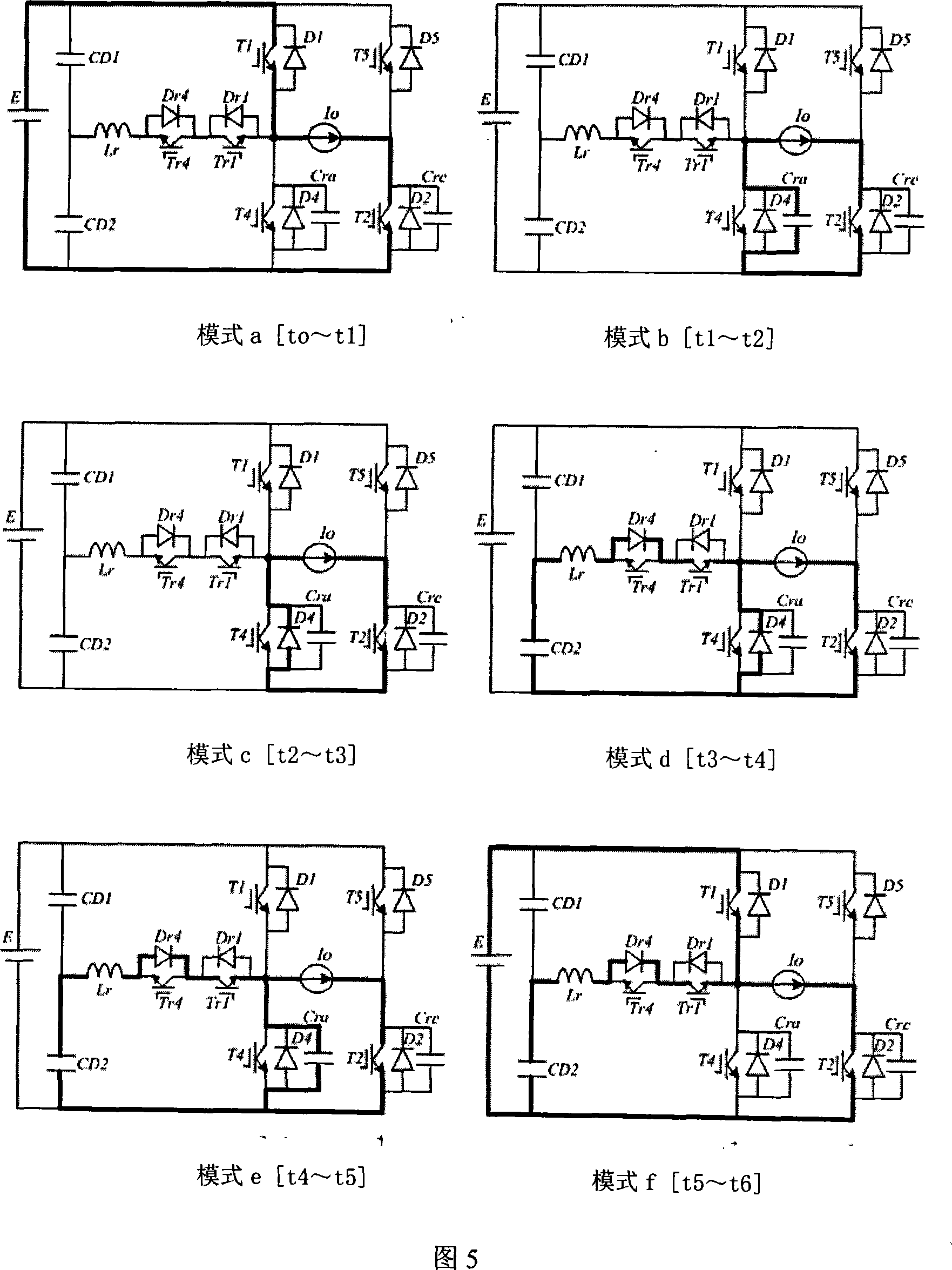

[0040]As shown in Figure 2, the present invention provides a novel resonant extremely soft-switching three-phase inverter applied to brushless DC motors, including: a DC power supply 1, an input voltage divider circuit 2, and a resonant pole auxiliary circuit 3 , a known three-phase inverter bridge 4 and a control circuit 6. The DC power supply 1 adopts the DC power supply E generated by battery series and parallel connection; the input voltage divider circuit 2 is formed by connecting two capacitors CD1 and CD2 in series, and the two ends of the voltage divider circuit 2 are connected to the DC power supply 1; the inverter bridge 4 converts the DC power into AC, each arm of the three-phase inverter bridge is composed of two IGBTs connected in series in the same direction, and each IGBT includes a power switching device Tx and an antiparallel freewheeling diode Dx (x ranges from 1 to 6), and The IGBTs of each lower bridge arm are connected in parallel with buffer capacitors Cr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com