System and method for regenerating reactivating and recovering FCC balance catalyst

A technology for balancing catalysts and recovery methods, which is applied in the field of regeneration and recovery systems for balanced catalysts. It can solve problems such as not fundamentally solving the problem of industrial waste outlets, limited amount and use of adsorbents, and uneven application effects. Catalyst consumption, high economic and social benefits, and the effect of increasing light oil yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be further described below in conjunction with the accompanying drawings and embodiments of the specification.

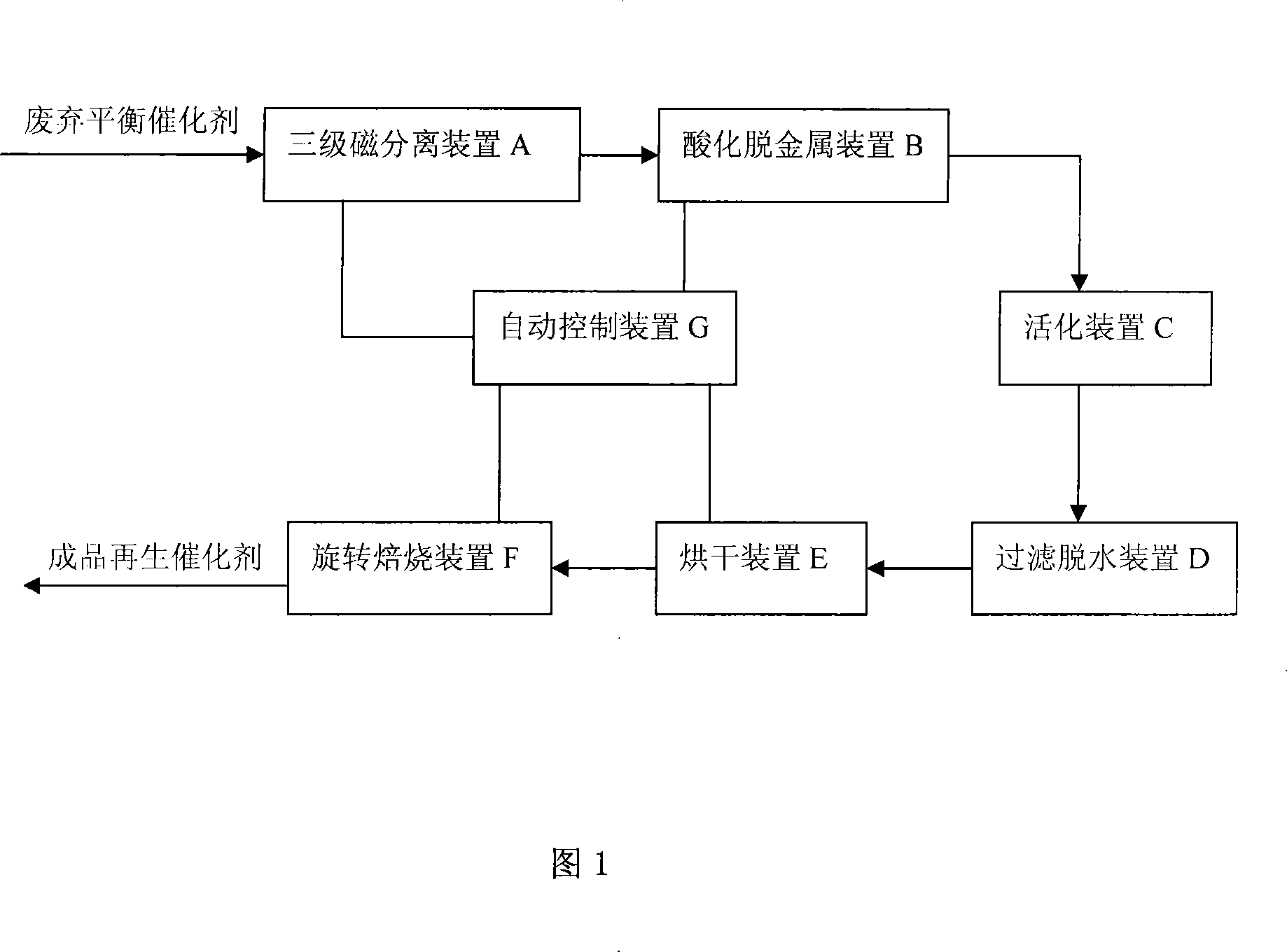

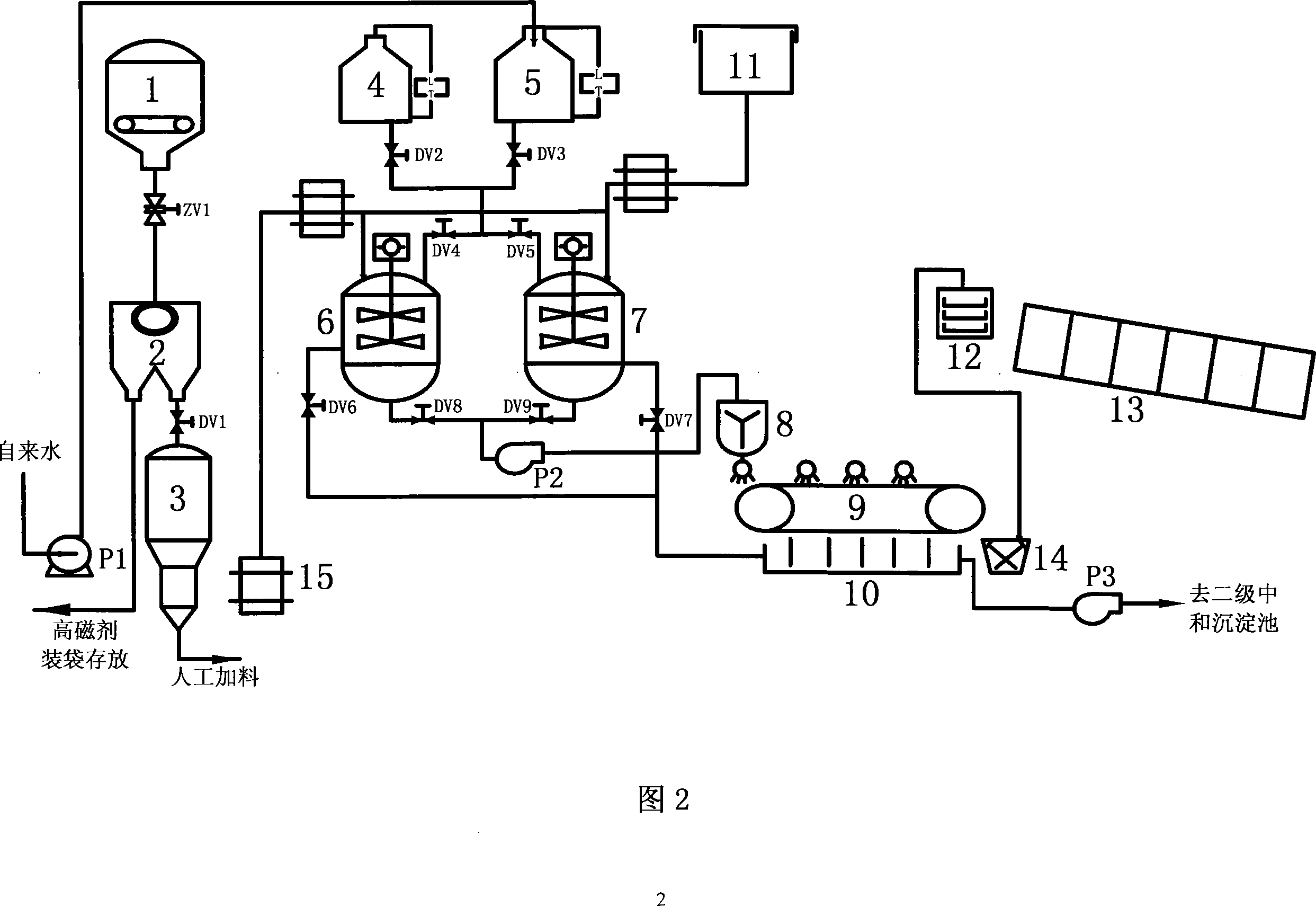

[0032] Schematic diagram of the FCC balancer regeneration recovery recovery process of the present invention, as shown in Figure 1: the waste balance catalyst to be treated enters the multi-stage magnetic separation device A through the material delivery system; the sorted low magnetic agent enters the acidification demetallization device B Middle; unload the high magnetic agent into bags; the slurry treated by the acidification demetallization device B enters the activation device C, and adds water and activator to the slurry after the acidification reaction; the slurry after a certain period of reaction passes through the filter dehydration device D is processed to form a filter cake; then enters the drying device E; the finished regenerated catalyst obtained after the filter cake is roasted in the rotary roasting device F flows ou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com