Inserting pipe digitalized design and manufacture method

A manufacturing method and a technology of inserting and repairing pipes, applied in the direction of electrical digital data processing, calculation, flange connection, etc., can solve the problems of high labor intensity, uncontrollable manufacturing quality, and low work efficiency, and achieve shortened manufacturing cycle and accurate measurement , The effect of saving manufacturing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

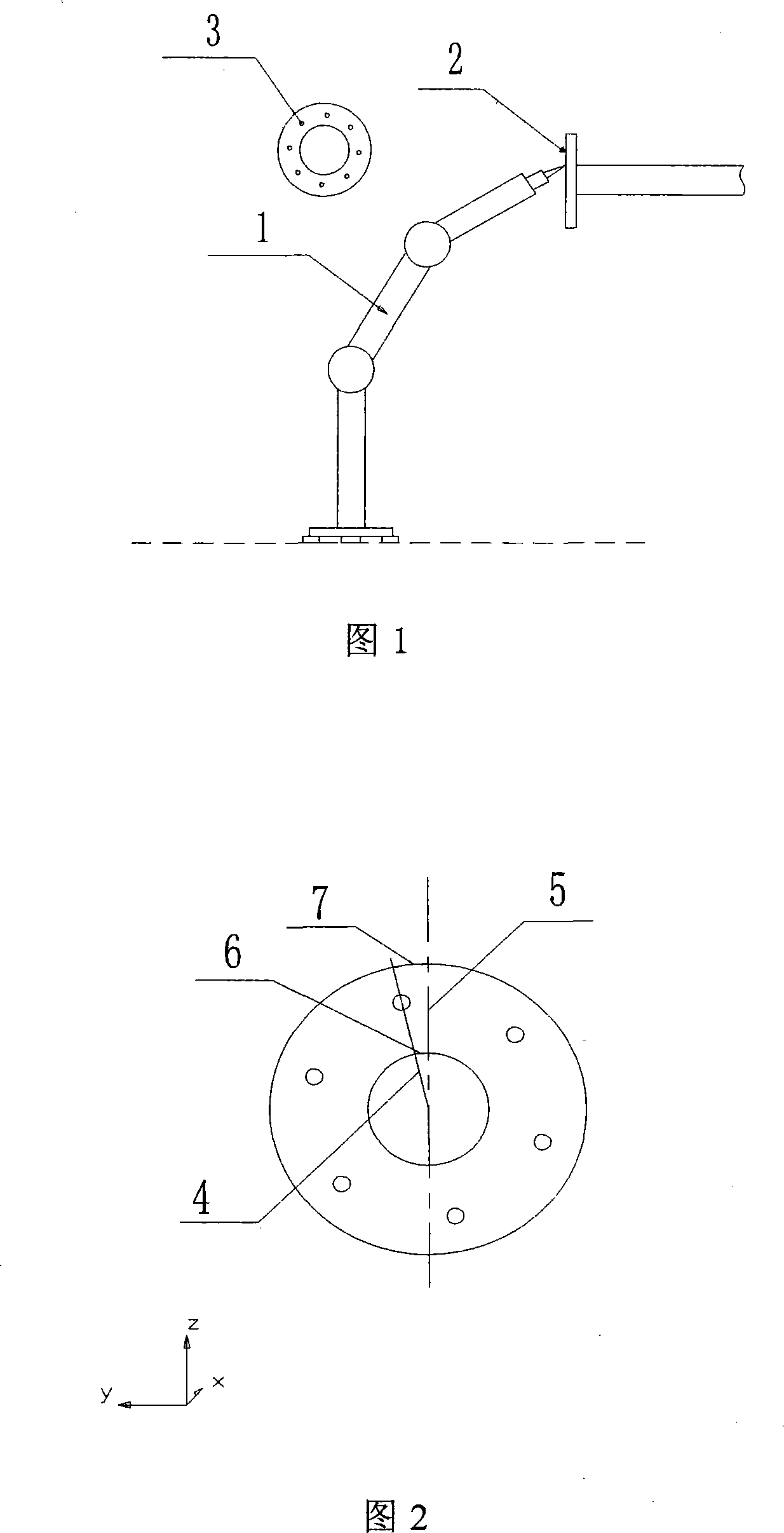

[0020] As shown in Figure 1, 1 is the digital measuring instrument used for measurement is the INFINITE series2000 contact measuring instrument, and its configuration is: infinite measuring arm (arm length 3.0m); standard measuring head (including 15mm steel ball, needle type measuring head Each one); measurement software is POWERINSPECT, SCANWORK; laser scanning head; measurement computer (Pentium 3 CPU). The on-site pipe parts that need to be measured are φ114×5mm stainless steel pipes under the flower aluminum plate of the main engine cabin of a ship. The beginning and end connectors of the pipes are flanges of 16100 CB / T46-1999 specification, named Fa-1 and Fa respectively. -2, 2 in Figure 1 is Fa-1, and 3 is Fa-2. The contact measuring instrument 1 is placed on the frame of the cabin unit, and the contact scanner 1 determines the spatial coordinate system measured by the measuring instrument through three sensors located at the feet of the measuring instrument.

[0021] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com