Method for producing silicon single crystals and silicon single crystal produced thereby

A cultivation method and technology of silicon single crystal, applied in the direction of single crystal growth, single crystal growth, chemical instruments and methods, etc., can solve the problems of poor productivity and yield, crystal fragmentation, easy occurrence, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

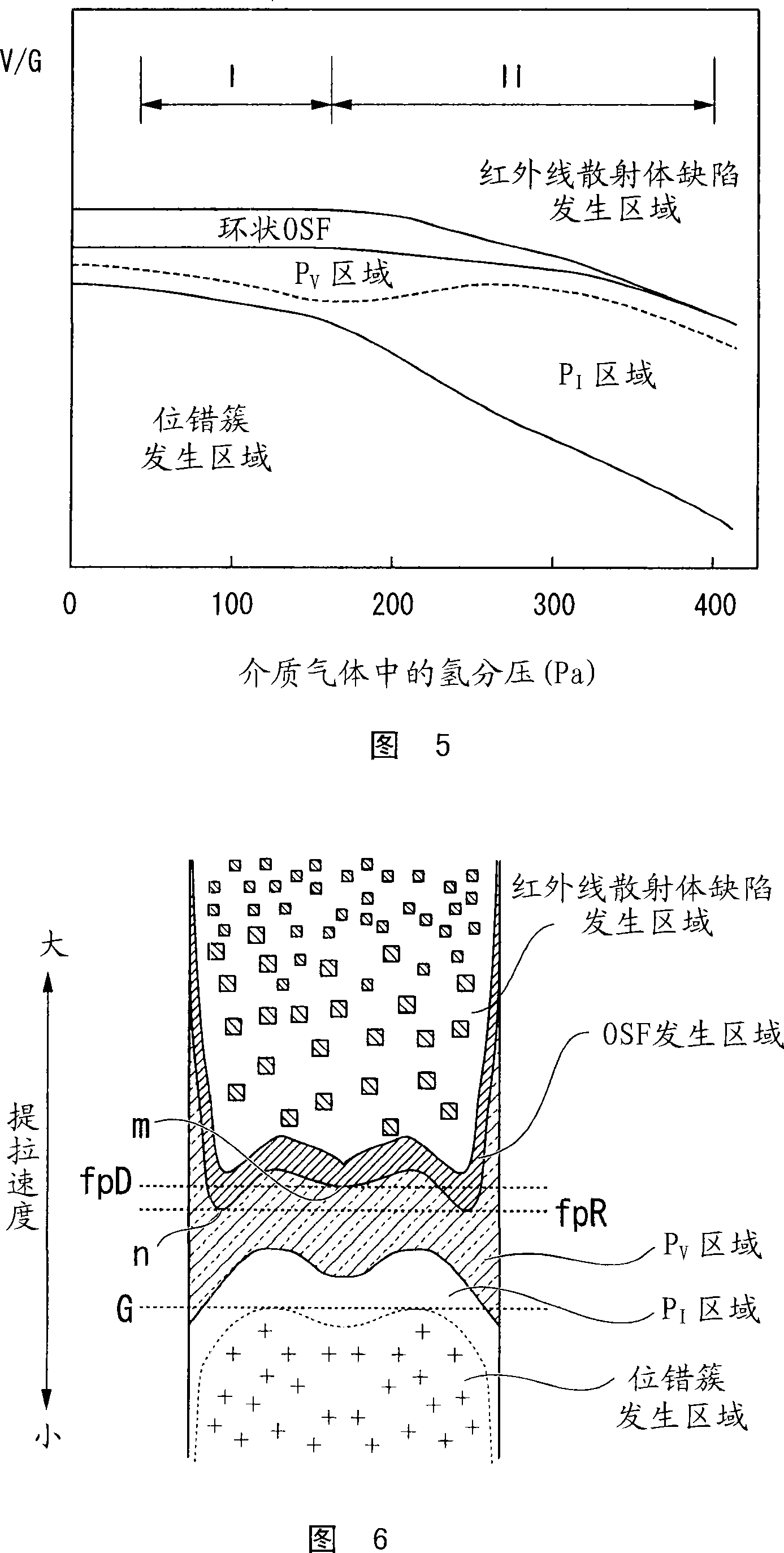

[0138] A cultivation device having the hot zone structure 1 shown in Table 1 was used. A mixed gas of argon and hydrogen with a molecular hydrogen partial pressure of 240 Pa was used as the medium gas for growing single crystals. Under the operating conditions set according to the method described above, a silicon single crystal which is a defect-free crystal is grown.

Embodiment 2

[0140] Using the cultivation device with hot zone structure 3 shown in Table 1, and using argon as the medium gas for growing single crystals, silicon single crystals which are defect-free crystals are grown.

Embodiment 3

[0142] Using a cultivation device having the hot zone structure 2 shown in Table 1, and using argon as the medium gas for growing single crystals, silicon single crystals which are defect-free crystals are grown.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com