Method for stabilization processing refuse incineration flying ash

A waste incineration fly ash and stabilization treatment technology is applied in the field of environmental engineering to achieve the effect of low product price, simple synthesis process and reducing the risk of re-pollution of the environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

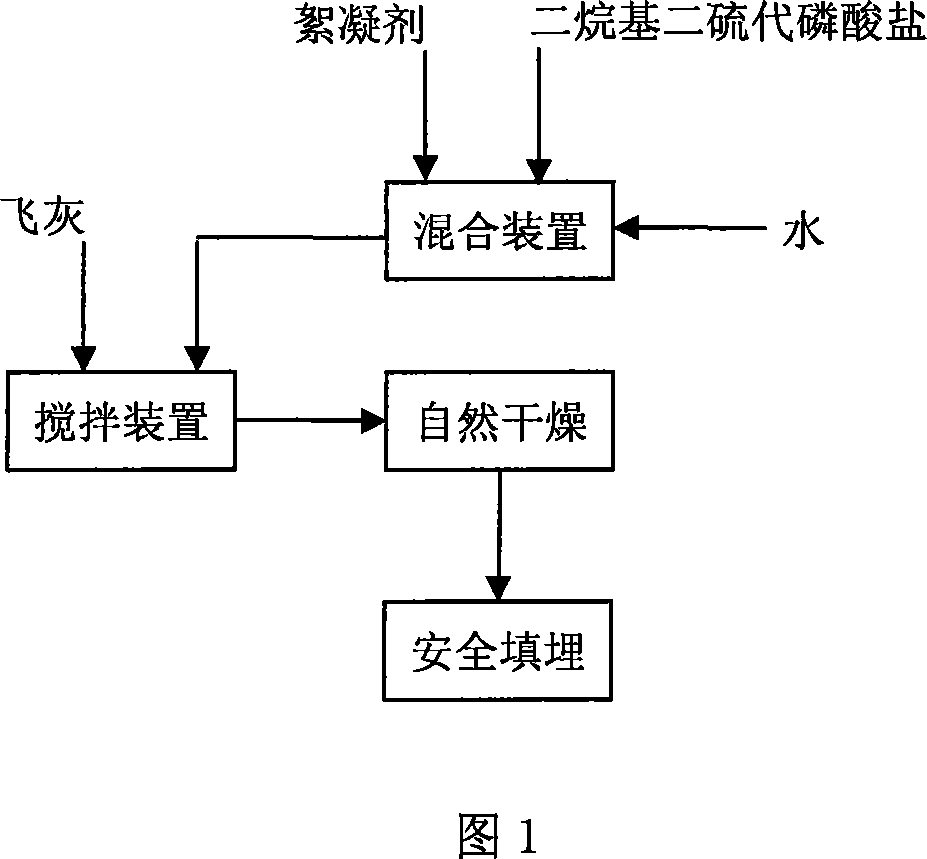

Method used

Image

Examples

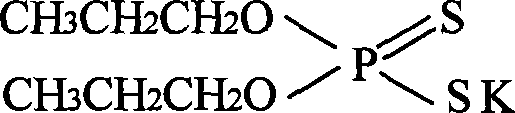

Embodiment 1

[0041] Take 100g of incineration fly ash sample A, and dissolve 1g of potassium dipropyldithiophosphate and 0.1g of aluminum sulfate in 90mL of water, add the stabilizer solution to the fly ash, and stir the above mixture for 20 minutes to make the heavy metals in the fly ash Completely react with dipropyl potassium dithiophosphate to form a thick mortar mixture, and then dry the above mixture under natural ventilation conditions and landfill safely. The weight ratio of fly ash to potassium dipropyl dithiophosphate is 100:1. According to GB5086.2-1997, the leaching toxicity test was carried out on the stabilized fly ash. The leaching concentration of lead exceeding the standard was 1.2mg / L, the leaching concentration of cadmium was 0.28mg / L, and the leaching concentration of chromium was 1.6mg / L. L, the leaching concentration of zinc is 5.0mg / L, meeting the hazardous waste identification standard and hazardous waste landfill pollution control standard.

Embodiment 2

[0043] Take 100g of incineration fly ash sample A, and dissolve 2.5g of diisopropyl ammonium dithiophosphate in 80mL of water, add the stabilizer solution to the fly ash, and stir the above mixture for 40 minutes to make the heavy metal in the mortar and diisopropyl ammonium Ammonium dithiophosphate reacts completely to form a thick mortar mixture. Then dry the above mixture under natural ventilation conditions and landfill safely. The weight ratio of fly ash to ammonium diisopropyldithiophosphate is 100:2.5. According to GB5086.2-1997, the leaching toxicity test was carried out on the stabilized fly ash. The leaching concentration of lead exceeding the standard was 1.0mg / L, the leaching concentration of cadmium was 0.19mg / L, and the leaching concentration of chromium was 1.4mg / L. L, the leaching concentration of zinc is 4.3mg / L, meeting the hazardous waste identification standard and hazardous waste landfill pollution control standard.

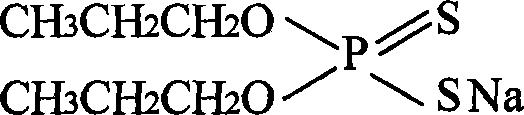

Embodiment 3

[0045]Take 100g of incineration fly ash sample B, take 1.0g of sodium dipropyldithiophosphate, 1.0g of potassium diisopropyldithiophosphate and 0.12g of polyaluminum chloride and dissolve it in 85mL of water, add the stabilizer solution to the fly ash In the ash, stir the above mixture for 25 minutes, so that the heavy metal in the mortar reacts completely with sodium dipropyl dithiophosphate and potassium diisopropyl dithiophosphate to form a thick mortar mixture. Then dry the above mixture under natural ventilation conditions and landfill safely. The weight ratio of fly ash to sodium dipropyldithiophosphate+potassium diisopropyldithiophosphate is 100:2.0. According to GB5086.2-1997, the leaching toxicity test was carried out on the stabilized fly ash. The leaching concentration of lead exceeding the standard was 1.1mg / L, the leaching concentration of cadmium was 0.20mg / L, and the leaching concentration of copper was 5.0mg / L. L, meet the hazardous waste identification standa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com