Method for feeding material and group soldering macrotype torpedo tank

A torpedo tank, large-scale technology, applied in the field of large-scale torpedo tank blanking and assembly welding, can solve the problems of difficult guarantee, small diameter, and inability to roll and form

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] The specific implementation of the present invention will be further described below in conjunction with the examples.

[0044] According to the large-scale torpedo tank blanking and assembly welding method of the present invention, comprise using computer to calculate the blanking of tank body, tank mouth, numerical control automatic cutting machine cuts, it is characterized in that comprising the following steps:

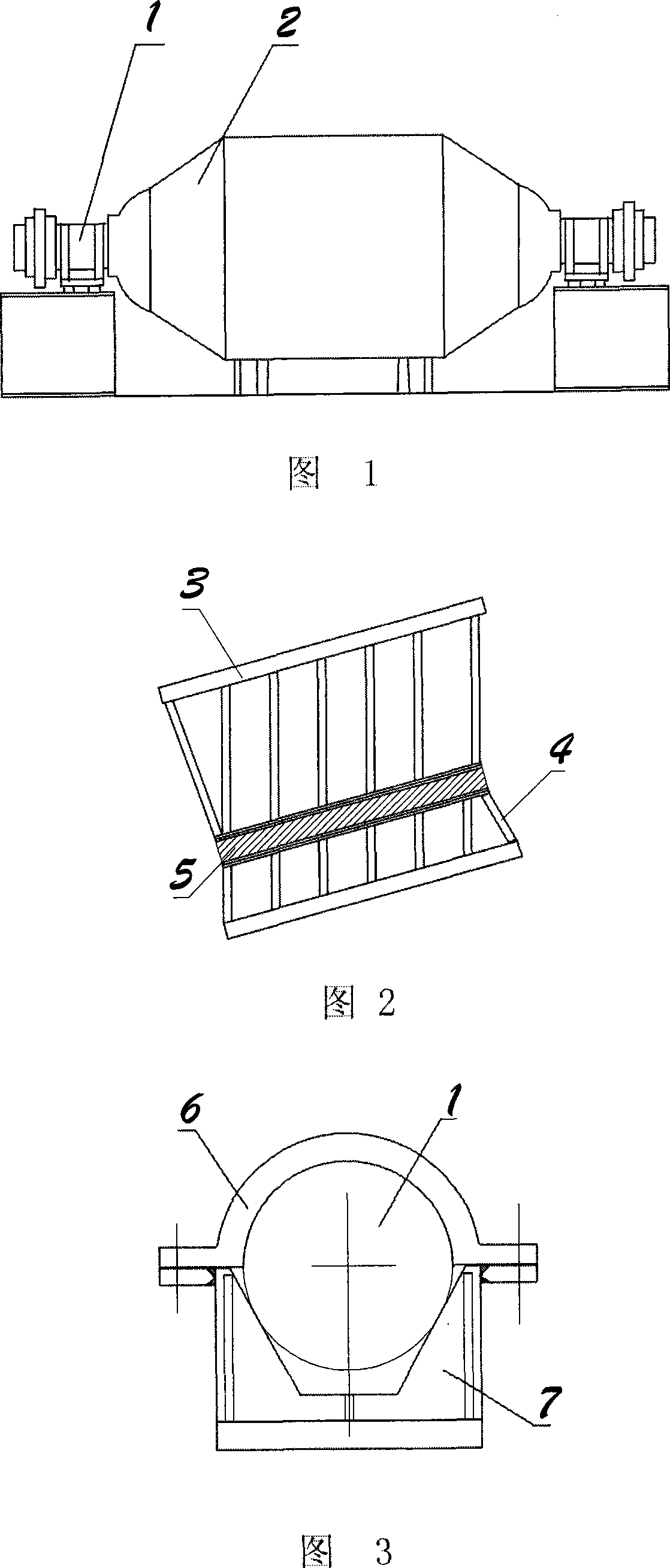

[0045] 1) The blanking and molding of the tank body and tank mouth (see Figure 1)

[0046] While carrying out the computer calculation of the blanking of the tank body and the tank mouth, and cutting by the CNC automatic cutting machine, the well-designed mold is used to complete the hot-press forming of the tank mouth, and the hot-press-formed can mouth is inspected ,

[0047] 2) Ensure the assembly accuracy of the large cylinder and the trunnions by using feasible molds and fixtures. The feasible molds and fixtures are: tank mouth molded molds to ensure ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Concentricity | aaaaa | aaaaa |

| body length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com