Technique for producing printing blanket airpillow layer

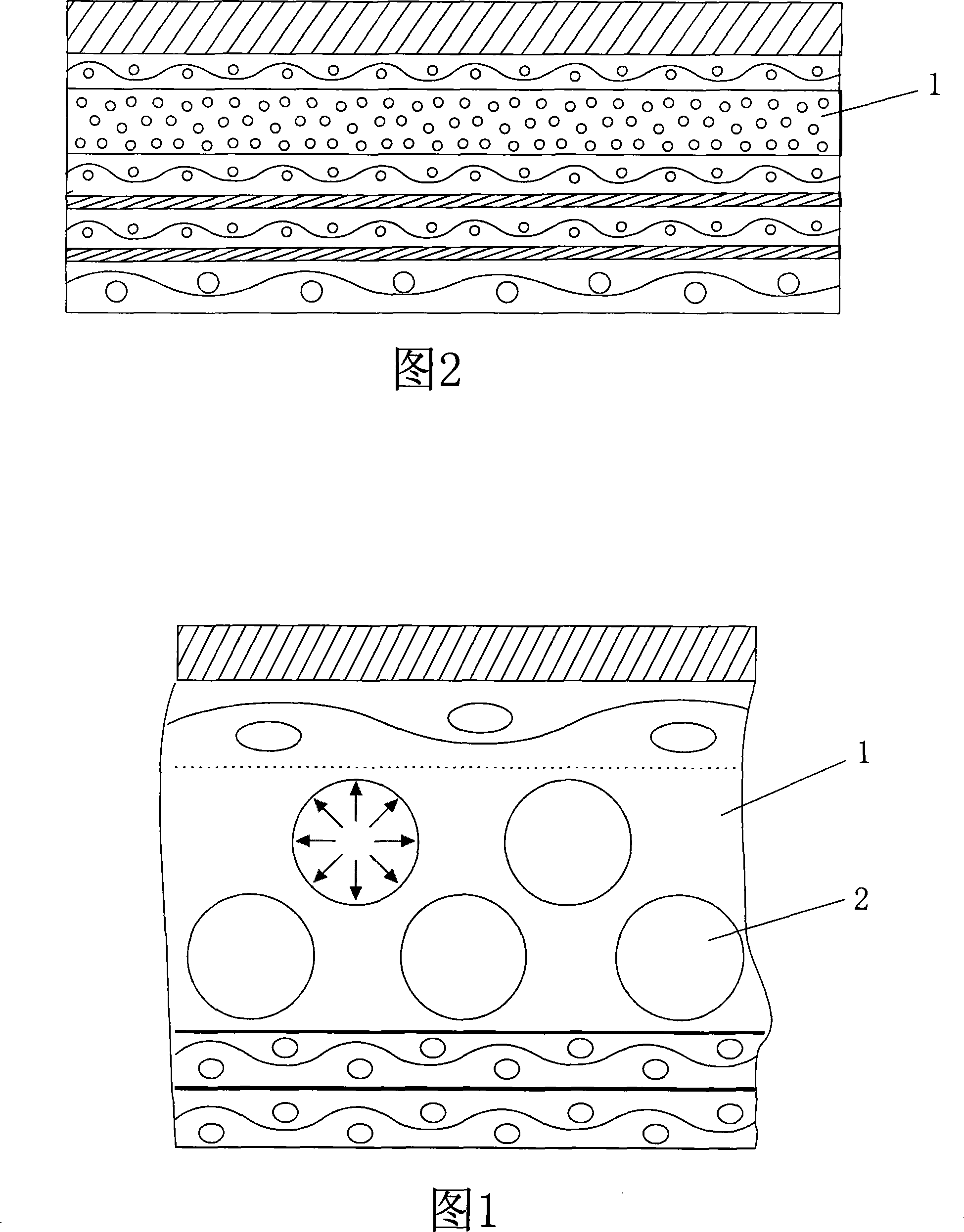

A production process and blanket technology, applied in the production process field of printing blanket air cushion layer, can solve the problems of blanket printing performance impact, poor recovery, poor elasticity, etc., achieve good elasticity, not easy to compress and deform, and improve printing performance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] 1) Add sulfur and ultra-fine chemical blowing agent--4,4'-oxobisbenzenesulfonyl hydrazide into the rubber compound and stir evenly. The weight ratio of the ultra-fine chemical foaming agent to the rubber compound is 1:10 ; Vulcanizing agent (sulfur) is conventional consumption;

[0022] 2), above-mentioned rubber compound is coated on the cotton cloth, is then compounded with the cotton cloth that the remaining three layers are coated with common rubber compound;

[0023] 3) Put the compounded semi-finished product into a drum vulcanizer for continuous vulcanization, the vulcanization pressure is 10 MPa, the vulcanization temperature is 140° C., and the vulcanization speed is 10 m / hour.

Embodiment 2

[0025] 1) Add sulfur and ultra-fine chemical blowing agent--4,4'-oxobisbenzenesulfonyl hydrazide into the rubber compound and stir evenly. The weight ratio of the ultra-fine chemical foaming agent to the rubber compound is 1:25 ; Vulcanizing agent (sulfur) is conventional consumption;

[0026] 2), above-mentioned rubber compound is coated on the cotton cloth, is then compounded with the cotton cloth that the remaining three layers are coated with common rubber compound;

[0027] 3) Put the compounded semi-finished product into a drum vulcanizer for continuous vulcanization, the vulcanization pressure is 15 MPa, the vulcanization temperature is 150° C., and the vulcanization speed is 12 m / hour.

Embodiment 3

[0029] 1) Add sulfur and superfine chemical foaming agent--4,4'-oxobisbenzenesulfonylhydrazide into the rubber compound and stir evenly. The weight ratio of superfine chemical foaming agent to rubber compound is 1:40 ; Vulcanizing agent (sulfur) is conventional consumption;

[0030] 2), above-mentioned rubber compound is coated on the cotton cloth, is then compounded with the cotton cloth that the remaining three layers are coated with common rubber compound;

[0031] 3) Put the compounded semi-finished product into a drum vulcanizer for continuous vulcanization, the vulcanization pressure is 18 MPa, the vulcanization temperature is 160°C, and the vulcanization speed is 15 m / h.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com