Preparation of kilogram-grade scale high-purity monosialotetrahexosylganglioside

A ganglioside and monosialic acid technology, applied in the field of biomedicine, can solve the problems of difficulty in extraction and separation of high-purity GM1, no reports and applications, and difficulty in large-scale clinical application. Increased yield and production efficiency, low product cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

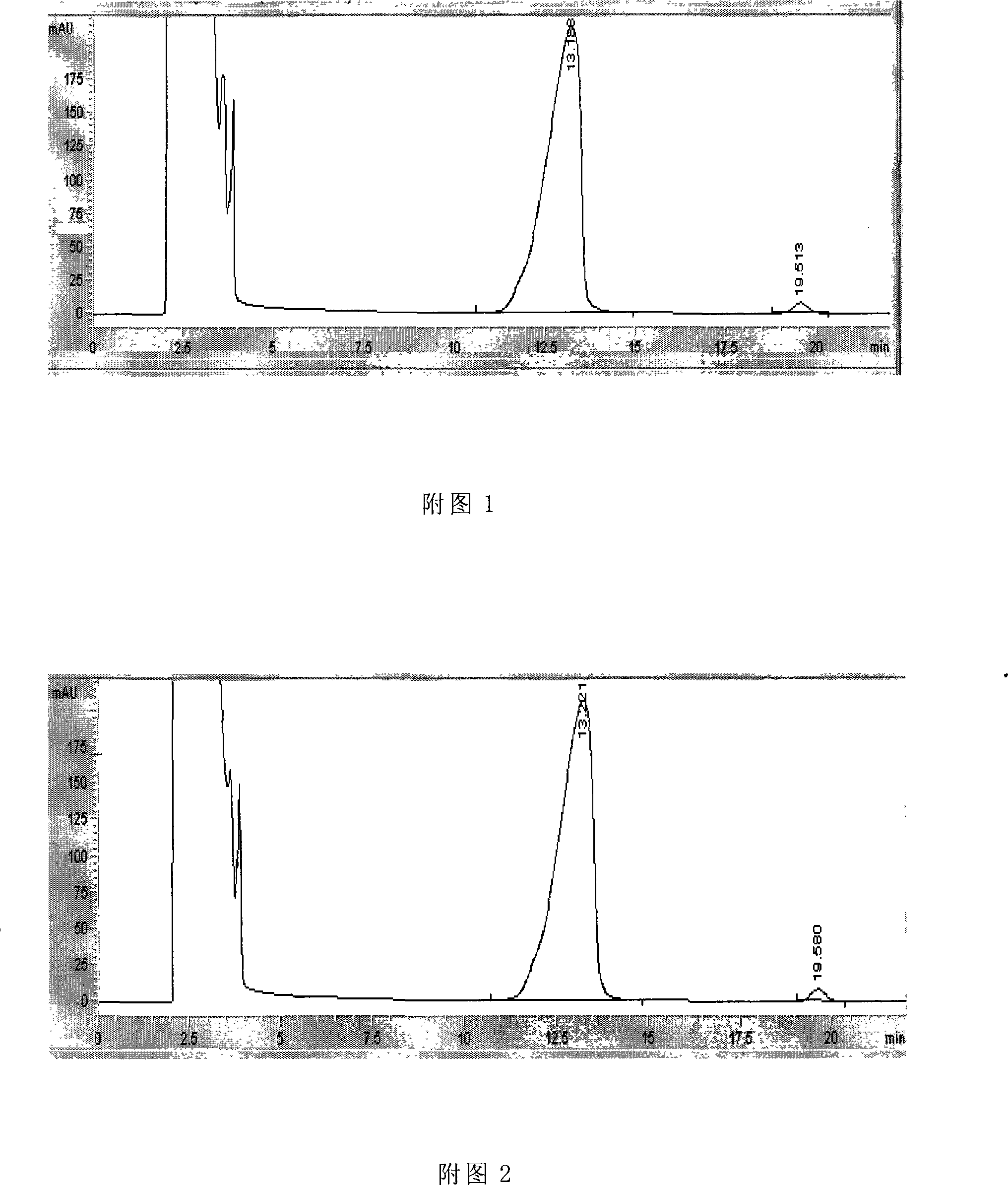

Image

Examples

Embodiment 1

[0023] Example 1 Preparation of high-purity GM1 freeze-dried powder

[0024] 1) Centrifuge the fresh pig brain tissue at 5000rpm to remove free water, pulverize it with a colloid mill, homogenize it at a high speed of 3000r / min for 30min, and pour it into the extraction tank and add 10 times the volume of methanol water (2:0.8) solution , stirred at a low temperature of 2°C for 12 hours, and extracted;

[0025] 2) Use a plate and frame filter to achieve solid-liquid separation of the extract, and then apply it to a macroporous adsorption resin D-101 chromatographic column, first wash off impurities with low-concentration methanol water (1:2), and then elute with anhydrous methanol Collecting the eluate containing gangliosides;

[0026] 3) The ganglioside eluate was concentrated in vacuum at 40°C and freeze-dried at -20°C, dissolved in 0.5M NaCl solution and adjusted to pH 3.5 with glacial acetic acid, hydrolyzed at 60°C for 3 hours, and used continuously during the hydrolysis...

Embodiment 2

[0030] Example 2 Preparation of high-purity GM1 freeze-dried powder

[0031]1) Centrifuge the fresh pig brain tissue at 5000rpm to remove free water, pulverize it with a colloid mill, homogenize it at a high speed of 3000r / min for 30min, and pour it into the extraction tank and add 10 times the volume of methanol water (2:1) solution , stirred at a low temperature of 8°C for 24 hours, and extracted;

[0032] 2) Use a plate and frame filter to achieve solid-liquid separation of the extract, and then apply it to a macroporous adsorption resin D-101 chromatographic column, first wash off impurities with low-concentration methanol water (1:3), and then elute with anhydrous methanol Collecting the eluate containing gangliosides;

[0033] 3) The ganglioside eluate was concentrated in vacuum at 80°C and freeze-dried at -60°C, dissolved in 0.5M NaCl solution and adjusted to pH 4.0 with glacial acetic acid, hydrolyzed at 75°C for 5 hours, and used continuously during the hydrolysis pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com