Polishing composition and polishing method

A grinding method and composition technology, applied to polishing compositions containing abrasives, chemical instruments and methods, grinding devices, etc., can solve the problems of large ceria abrasive grains and complicated washing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

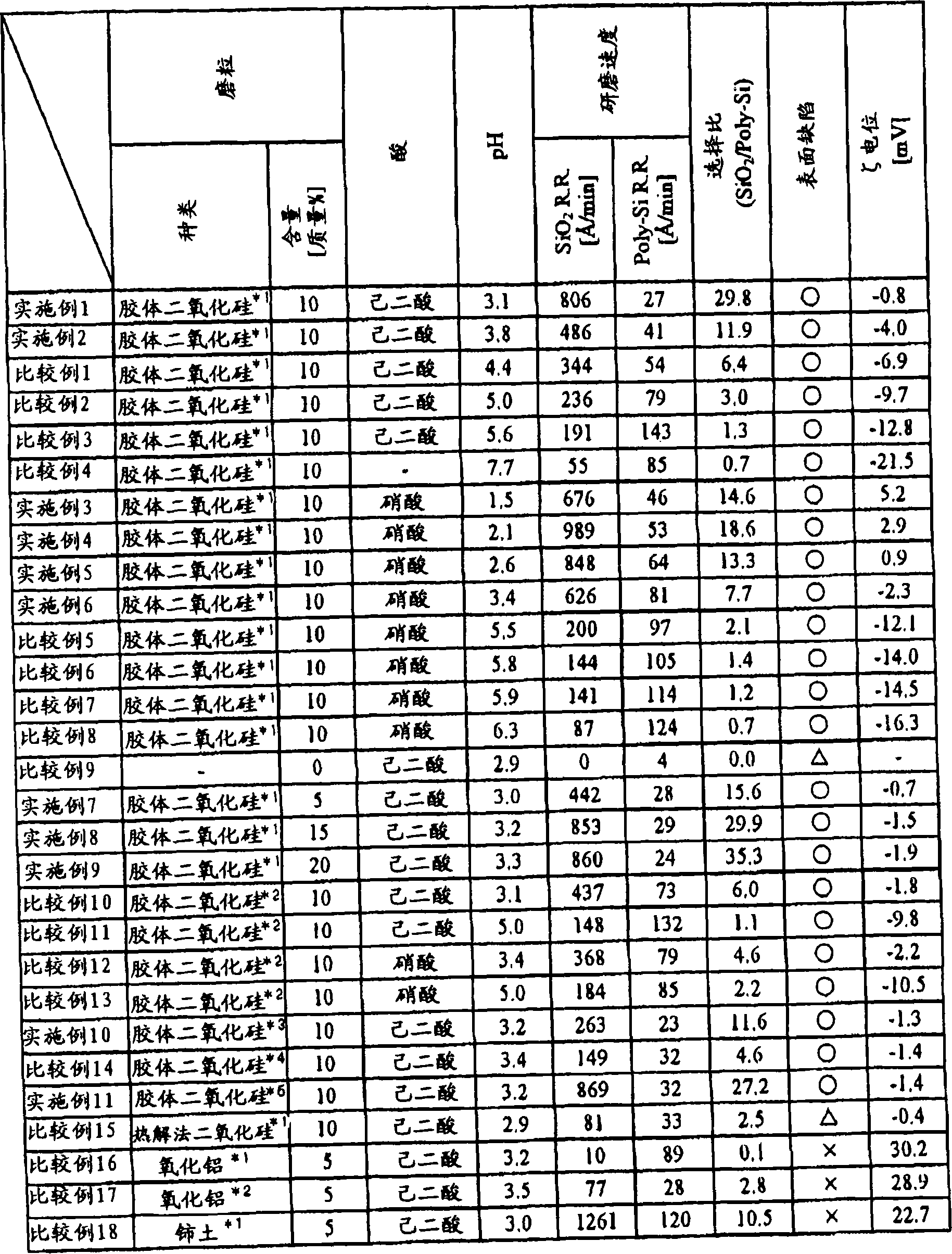

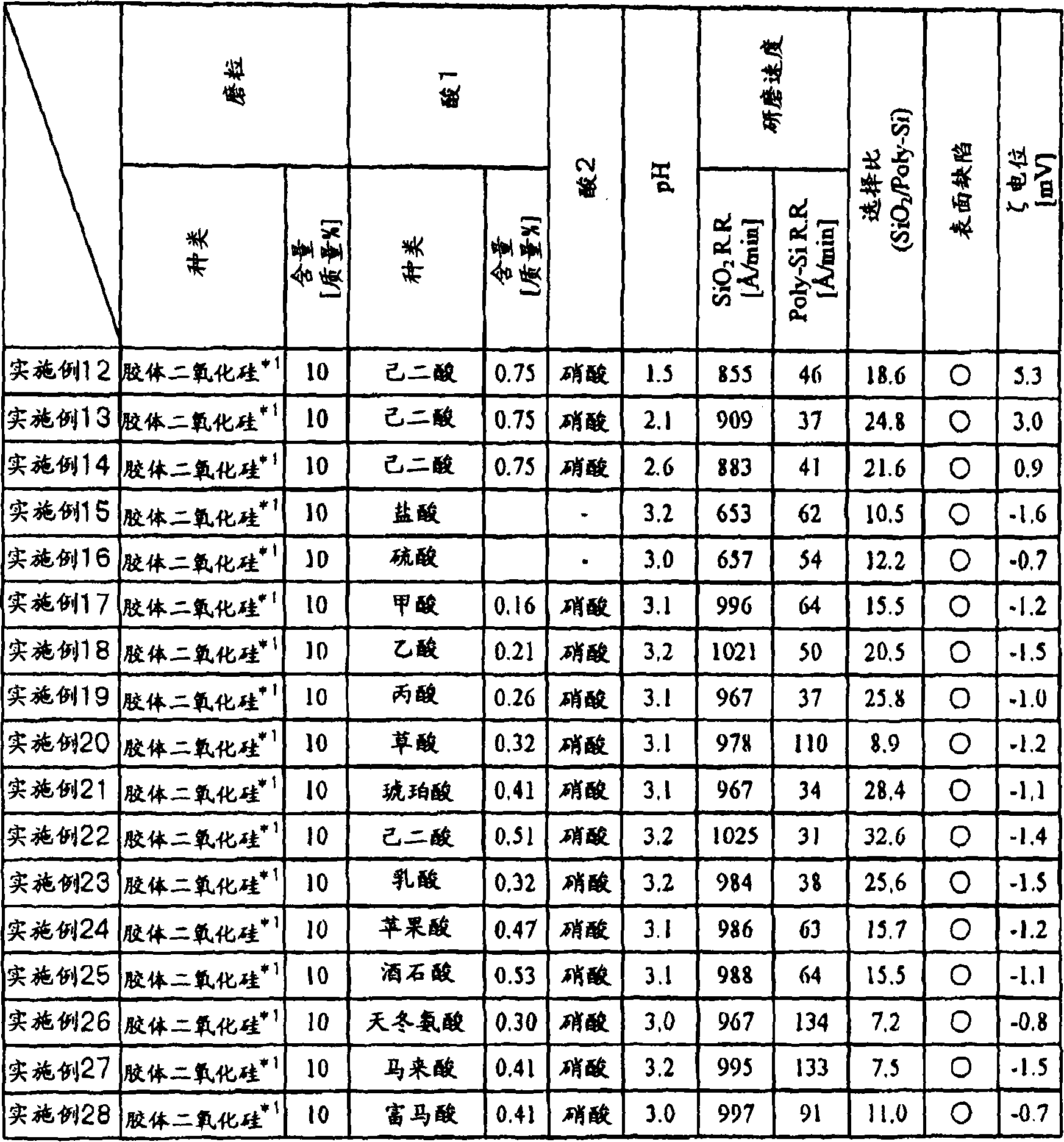

[0015] One embodiment of the present invention is described below.

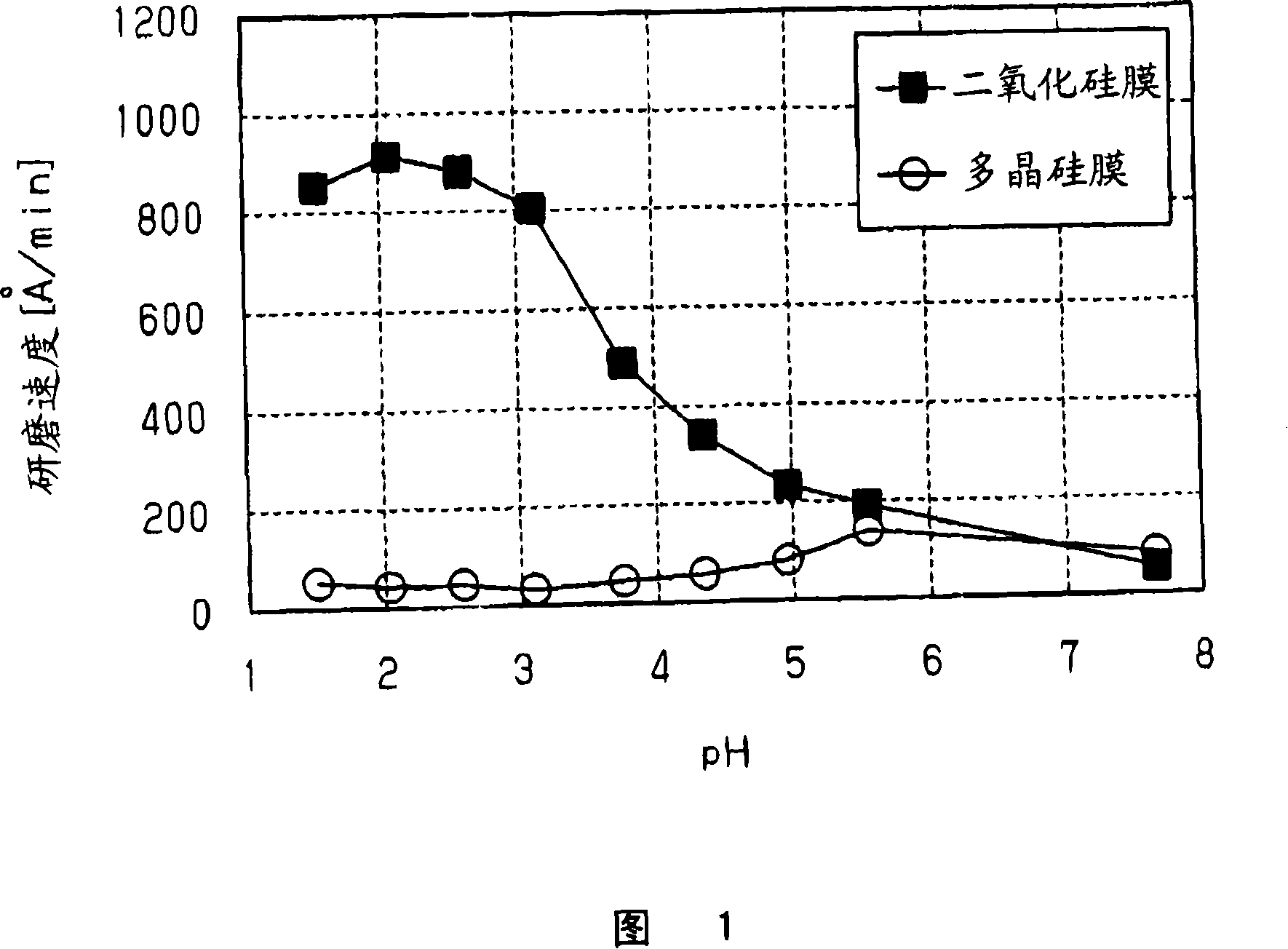

[0016] The polishing composition of this embodiment is prepared by mixing colloidal silica, an acid, and water so that the pH becomes 1-4. Thus, the polishing composition contains colloidal silica, acid and water. This polishing composition is suitably used for polishing a silicon dioxide film, especially for polishing a silicon dioxide film provided on a silicon substrate or a polysilicon film.

[0017] The above-mentioned colloidal silica has the function of mechanically polishing the silica film, and exerts the function of increasing the polishing rate of the silica film with the polishing composition. Colloidal silica can be synthesized by various methods, but the sol-gel method is preferable because it minimizes the contamination of impurity elements. Synthesis of colloidal silica by the sol-gel method is usually performed by dropping methyl silicate into a solvent containing methanol, ammonia, and wat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com