High-strength shipbuilding section and production method thereof

A technology of marine steel plate and production method, applied in the field of high-strength marine steel plate and its production, can solve the problems of increasing the production cost of high-strength marine steel plate, restricting high-strength marine steel plate, unable to realize mass production, etc., and achieves good welding performance and excellent welding performance. The effect of mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

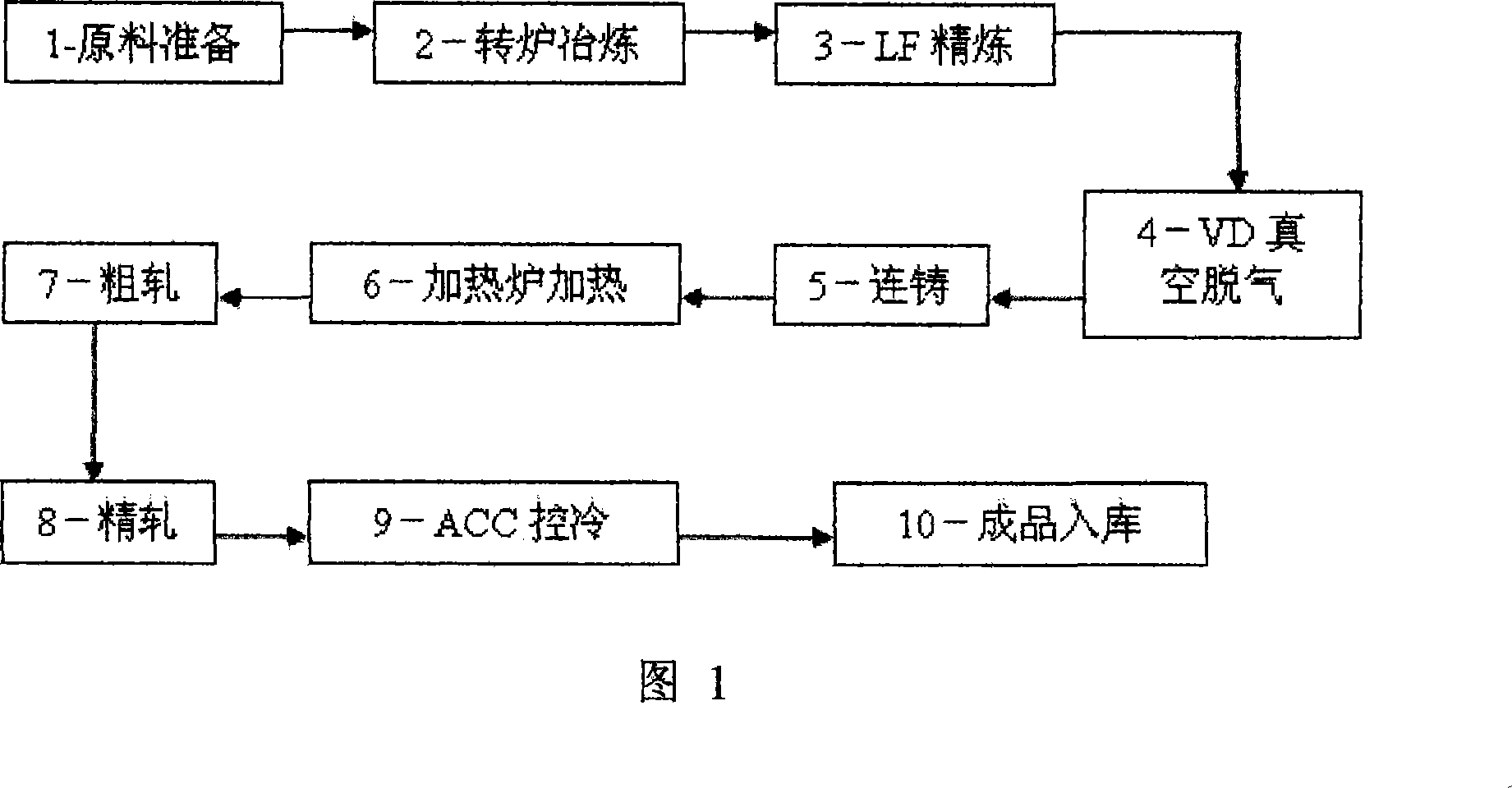

Image

Examples

Embodiment 1

[0028]Add molten iron and steel scrap during converter smelting, the ratio of molten iron and steel scrap is 85%-95% to 5%-15%; then add ferroalloy ferrosilicon: Si≥72.0%, Mn≤0.5%, S≤0.02%, P≤ 0.04%, C≤0.2%, Cr≤0.5%, iron balance; ferromanganese: Si≤1.5%, Mn≥78.0%, S≤0.03%, P≤0.20%, C≤1.5%, iron balance; titanium Iron: 25.0%≤Ti≤35.0%, Al≤8.0%, Si≤4.50%, Mn≤2.50%, P≤0.05%, S≤0.03%, C≤0.10%, Cu≤0.40%, iron balance; niobium Iron: carbon ≤ 0.05%, niobium 60-70%, silicon ≤ 2%, aluminum ≤ 2.5%, iron balance; molybdenum ferro:: 55.0% ≤ Mo ≤ 65.0%, Si ≤ 1.5%, S ≤ 0.10%, P ≤0.05%, C≤0.10%, Cu≤0.50%, Sb≤0.05%, Sn≤0.06%, iron balance; nickel plate: nickel 99.9%~100%, impurity balance; the final addition ratio is listed as Si≤2.0 %, 30.0% ≤ Mn ≤ 35.0%, S ≤ 0.05%, P ≤ 0.20%, C ≤ 2.0%, 20.0% ≤ Al ≤ 26.0%, Cu ≤ 0.5%, the rest of Fe is smelted by composite deoxidized alloy aluminum manganese ferroalloy. Refined in LF furnace, refining temperature: 1500-1650°C; composition fine-tuning, slagg...

Embodiment 2

[0030] Add molten iron and steel scrap during converter smelting, the ratio of molten iron and steel scrap is 85%-95% to 5%-15%; then add ferroalloy ferrosilicon: Si≥72.0%, Mn≤0.5%, S≤0.02%, P≤ 0.04%, C≤0.2%, Cr≤0.5%, iron balance; ferromanganese: Si≤1.5%, Mn≥78.0%, S≤0.03%, P≤0.20%, C≤1.5%, iron balance; titanium Iron: 25.0%≤Ti≤35.0%, Al≤8.0%, Si≤4.50%, Mn≤2.50%, P≤0.05%, S≤0.03%, C≤0.10%, Cu≤0.40%, iron balance; niobium Iron: carbon≤0.05%, niobium 60-70%, silicon≤2%, aluminum≤2.5%, iron balance; molybdenum iron: 55.0%≤Mo≤65.0%, Si≤1.5%, S≤0.10%, P≤ 0.05%, C≤0.10%, Cu≤0.50%, Sb≤0.05%, Sn≤0.06%, iron balance; ferrochromium: Cr≥60.0%, C≤2.0%, Si≤2.5%, P≤0.04%, S≤0.03%, iron balance; the final addition ratio is listed as Si≥35.00%, Al≥12.00%, Ba≥18.00%, Al+Ba≥30.00%, P≤0.05%, S≤0.10% composite deoxidized alloy silicon Aluminum barium is smelted, refined by LF furnace, refining temperature: 1500-1650°C; composition fine-tuning, slag deoxidation, refining time ≥ 35min, argon blo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Yield strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

| Low temperature impact toughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com