Direct-driving single needle industrial sewing machine control system

A control system, direct-drive technology, applied in the direction of sewing machine control devices, sewing machine components, electrical program control, etc., can solve the problems of technological gaps, lack of independent innovation, etc., to achieve stable sewing speed, more convenient man-machine interface The effect of improving technical indicators

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

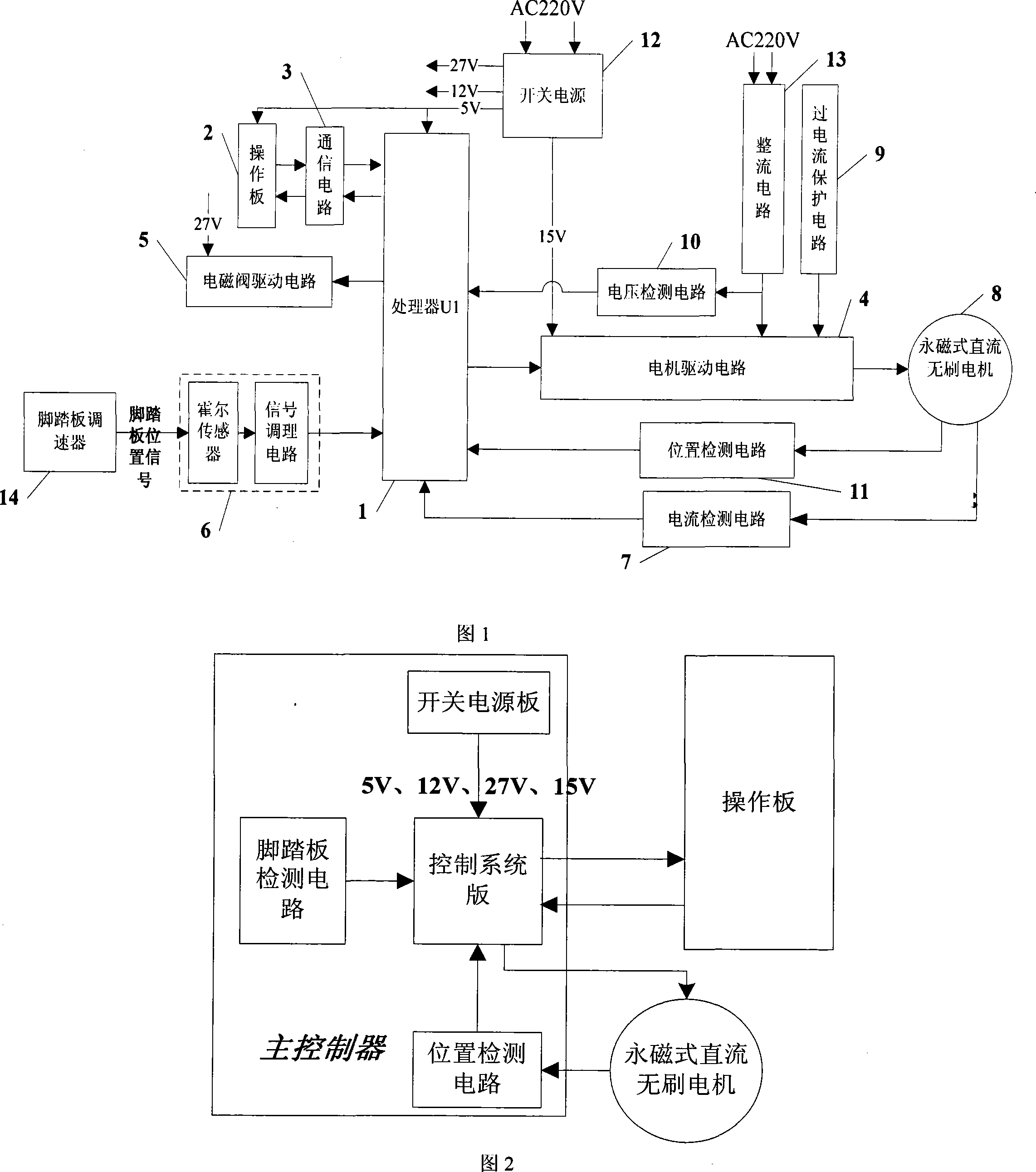

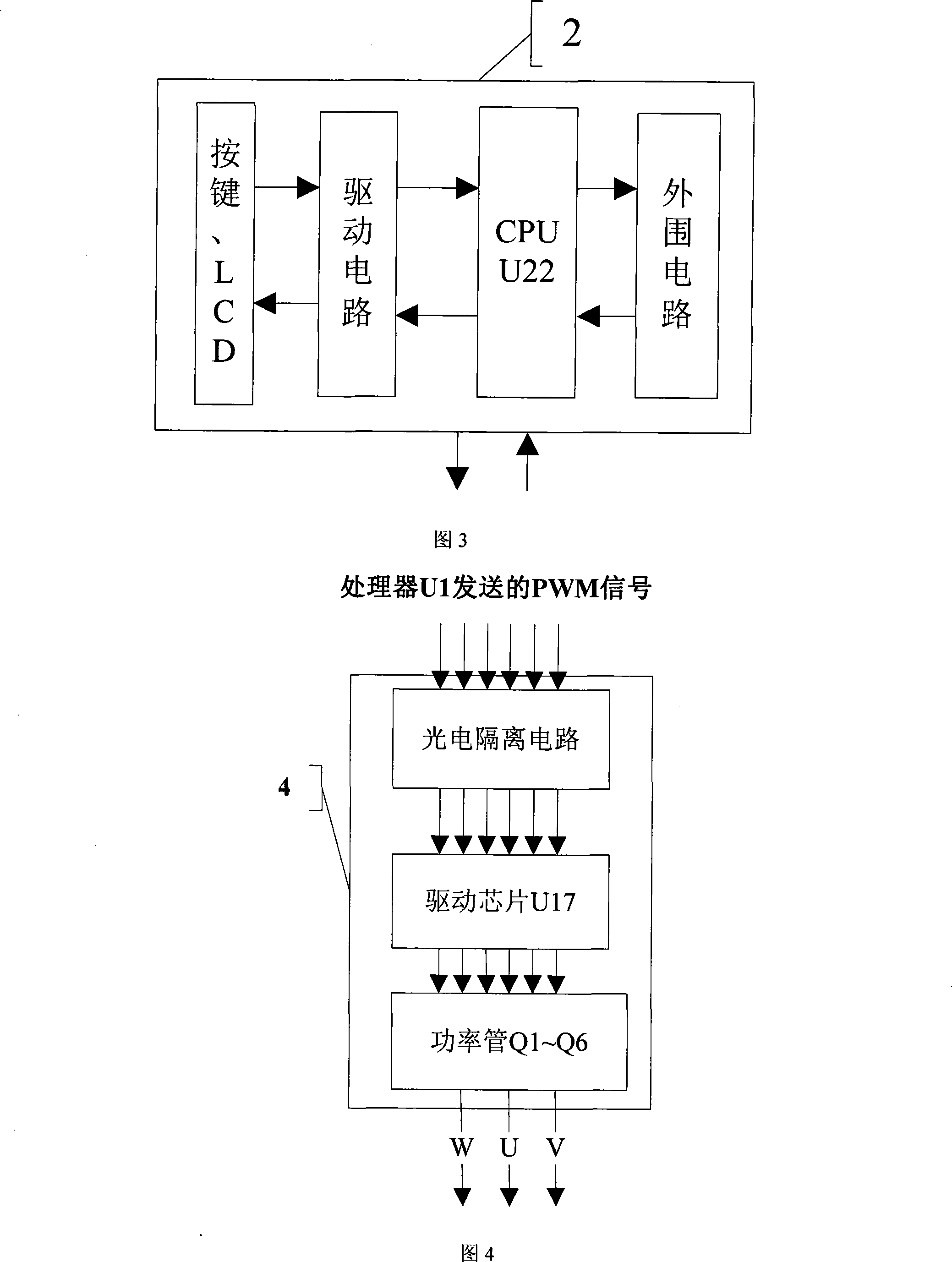

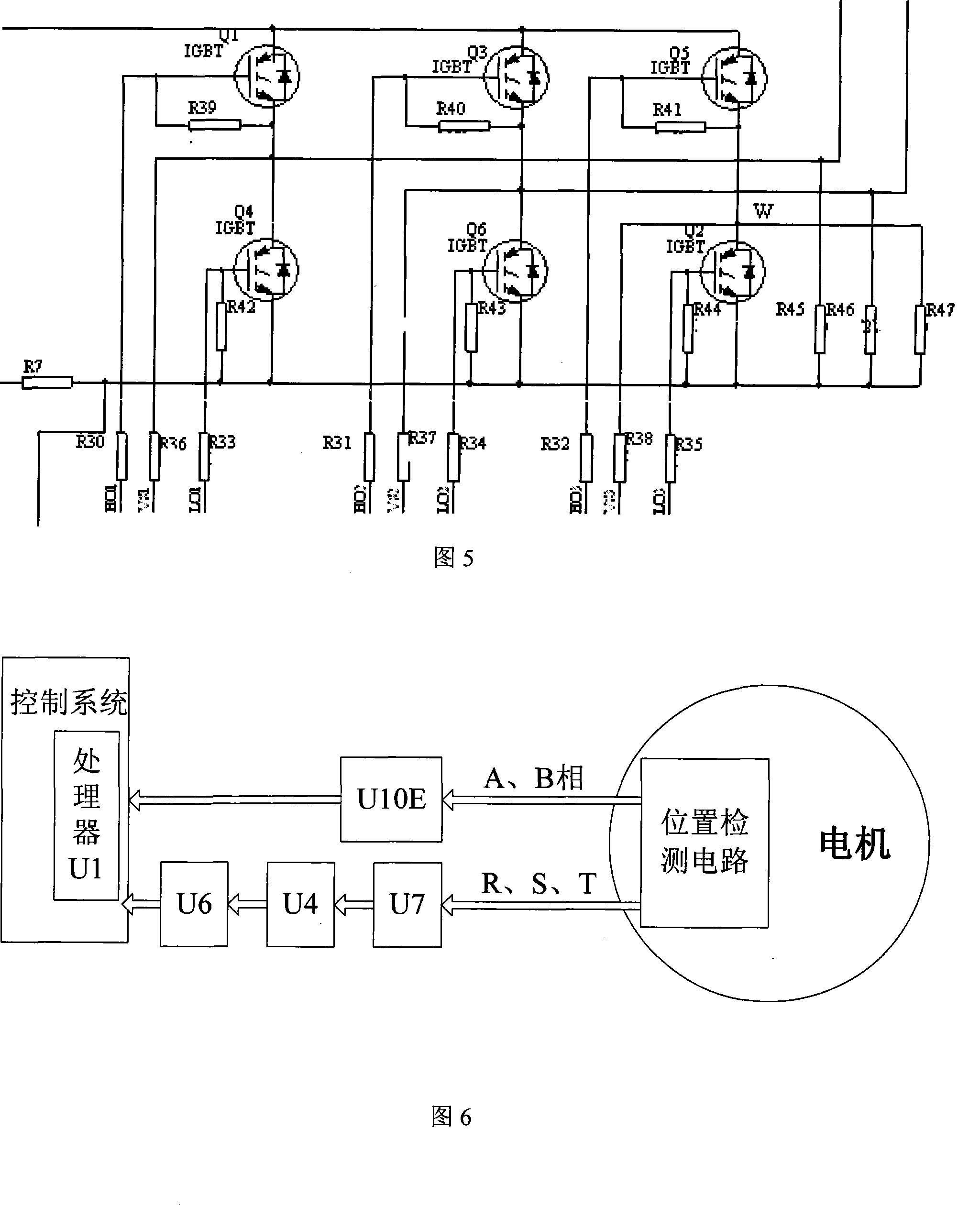

[0056] Please refer to Fig. 1, the direct-drive single-needle industrial lockstitch machine control system of the present invention includes a processor U11, an operation panel 2, a communication circuit 3, a motor drive circuit 4, a solenoid valve drive circuit 5, and a pedal detection Circuit 6, current detection circuit 7, permanent magnet brushless DC motor 8, overcurrent protection circuit 9, voltage detection circuit 10, position detection circuit 11, switching power supply 12, rectification circuit 13, pedal governor 14. Among them, the operation board 2 is one piece alone, forming the operation board of the system;

[0057] The operation panel 2 and the processor U1 carry out two-way data transmission through the communication circuit 2; the motor drive circuit 4 is respectively connected with the overcurrent protection circuit 9, the rectification circuit 13, the permanent magnet brushless DC motor 8, and the processor U1, wherein the overcurrent The protection circui...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com