Alkaline-based developer composition

A composition and developer technology, applied in the processing of photosensitive materials, etc., can solve problems such as metal ion residues, residues, and impact on product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

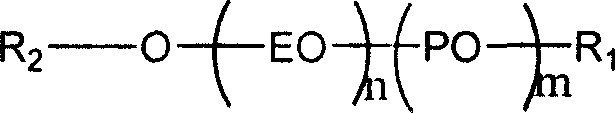

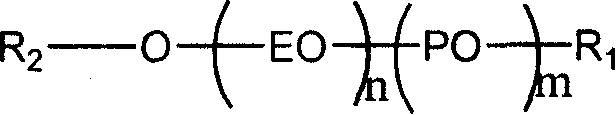

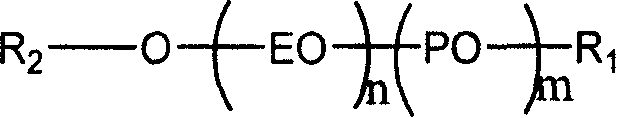

Image

Examples

Embodiment Construction

[0009] In order to make your examiner understand the main technical content and implementation mode of the present invention, the description is as follows with the help of drawings:

[0010] The alkaline developing solution composition of the present invention is a kind of alkaline developing solution applied to the image formation of photosensitive resin after ultraviolet (UV) exposure, and its composition includes:

[0011] (A) Pure water is mainly used as the dispersing medium of the developer. Since water itself is not toxic and flammable, using pure water as the dispersing medium of the developing solution is not only low cost, but also the raw material itself is easier to manage, and the waste liquid Handling is also easier.

[0012] (B) at least one basic compound, mainly used to dissolve the resin of the non-image part, which can be selected from: (1) alkali metal, alkaline earth metal hydroxide; (2) alkali metal, alkaline earth metal carbonate and bicarbonate; or (3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com