Method for preparing WC-Co series nano composite hard alloy powder

A cemented carbide and nano-composite technology is applied in the field of ultrafine WC-Co series cemented carbide powder preparation to achieve the effects of improving surface energy, high processing efficiency and good industrial application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

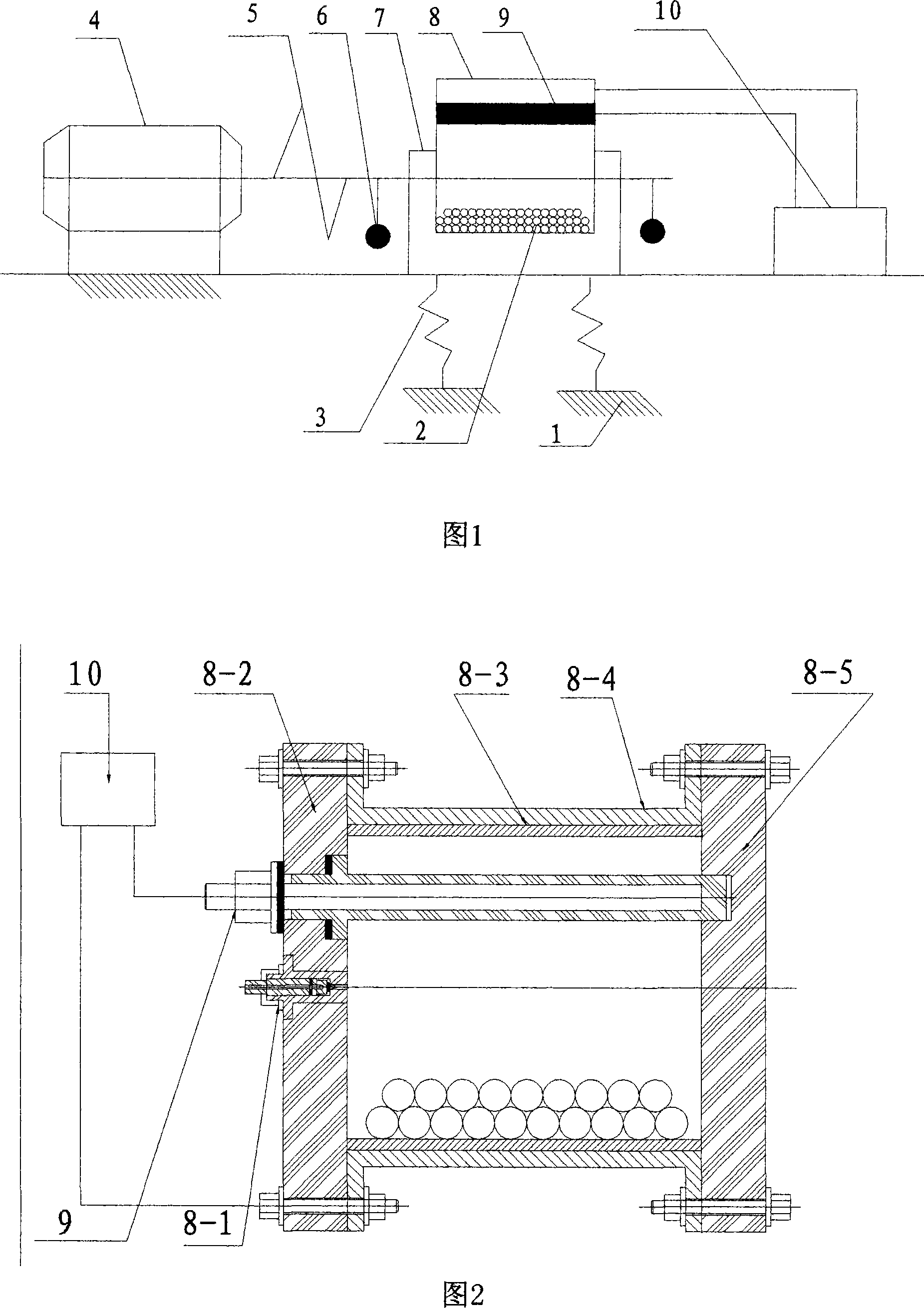

[0028] Embodiment 1, preparation of WC-20Co nanocomposite cemented carbide powder:

[0029] Using the above-mentioned corona discharge plasma-assisted high-energy ball mill, the total volume of selected balls accounts for 75% of the volume of the ball mill tank, wherein the number of balls with a diameter of 22mm accounts for 15% of the total number of balls, and the number of balls with a diameter of 18mm accounts for 75% of the total volume of the ball mill. 75% of the number of grinding balls, the number of grinding balls with a diameter of 10mm accounts for 10% of the total number of grinding balls, and the loose volume of W, C, and Co raw materials to be processed accounts for 130% of the gap between the grinding balls.

[0030] Preparation of WC-20Co nanocomposite cemented carbide powder comprises the following steps:

[0031] (1) Install the front cover plate and electrode rod of the ball milling tank, and connect the ball milling tank and electrode rod to the positive ...

Embodiment 2

[0036] Embodiment 2, preparation of WC-10Co nanocomposite cemented carbide powder:

[0037] Using the above-mentioned corona discharge plasma-assisted high-energy ball mill, the total volume of the selected balls accounts for 70% of the volume of the ball mill tank, wherein the number of balls with a diameter of 20mm accounts for 10% of the total number of balls, and the number of balls with a diameter of 15mm accounts for 70% of the total volume of the ball mill. 80% of the number of grinding balls, the number of grinding balls with a diameter of 10mm accounts for 10% of the total number of grinding balls, and the loose volume of W, C, and Co raw materials to be processed accounts for 60% of the gap between the grinding balls.

[0038] Preparation of WC-10Co nanocomposite cemented carbide powder comprises the following steps:

[0039] (1) Install the front cover plate and electrode rod of the ball milling tank, and connect the ball milling tank and electrode rod to the positi...

Embodiment 3

[0044] Embodiment 3, preparation of pure WC nanocomposite cemented carbide powder:

[0045] Using the above-mentioned corona discharge plasma assisted high-energy ball mill, the process conditions for processing W, C, and Co are basically the same as those for preparing WC-20Co cemented carbide. The atomic ratio of the high-quality alloy components is added, in which 5% of carbon is added, and Co is not added at this time; the gas medium to be filled is N2; the voltage of the plasma power supply is 10KV, and the frequency is 5KHz; the synthesis temperature is 1100°C, and the pressure of the heat source is 0.1 MPa. The product is pure WC nanocomposite cemented carbide powder.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com