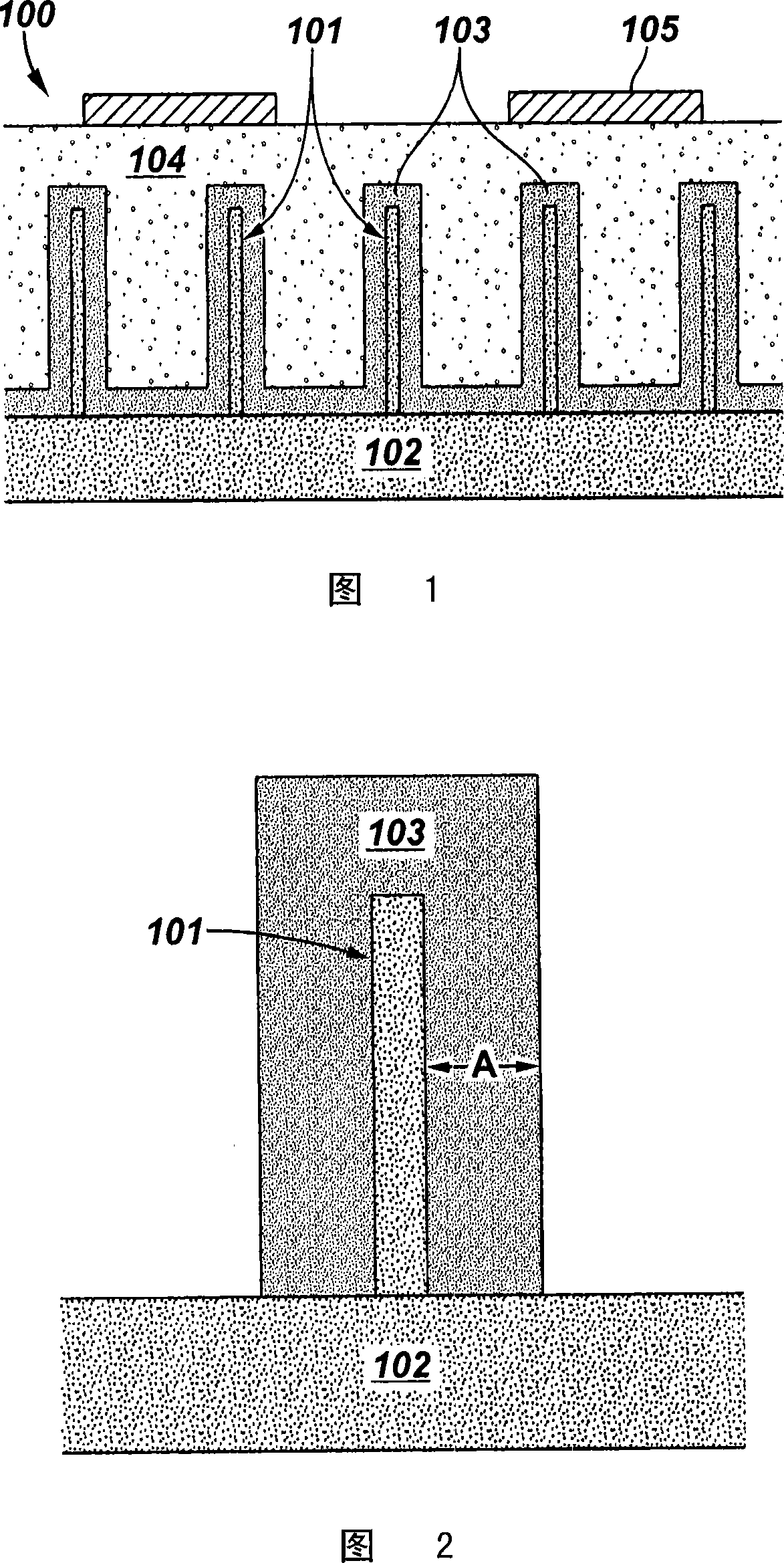

Graded hybrid amorphous silicon nanowire solar cells

A technology of amorphous layer and nanohole, applied in nanotechnology, circuits, electrical components, etc., can solve problems such as reducing device performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

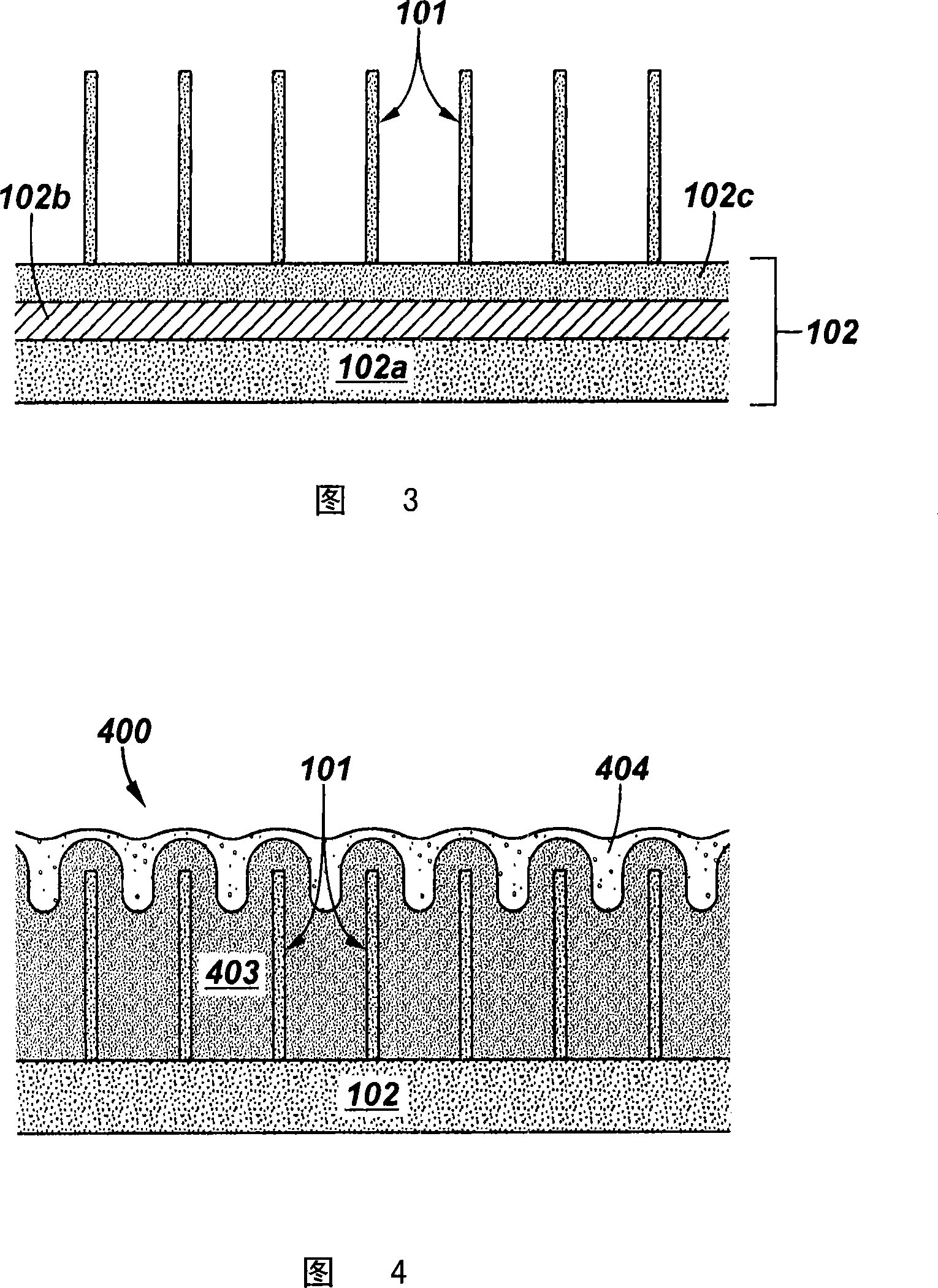

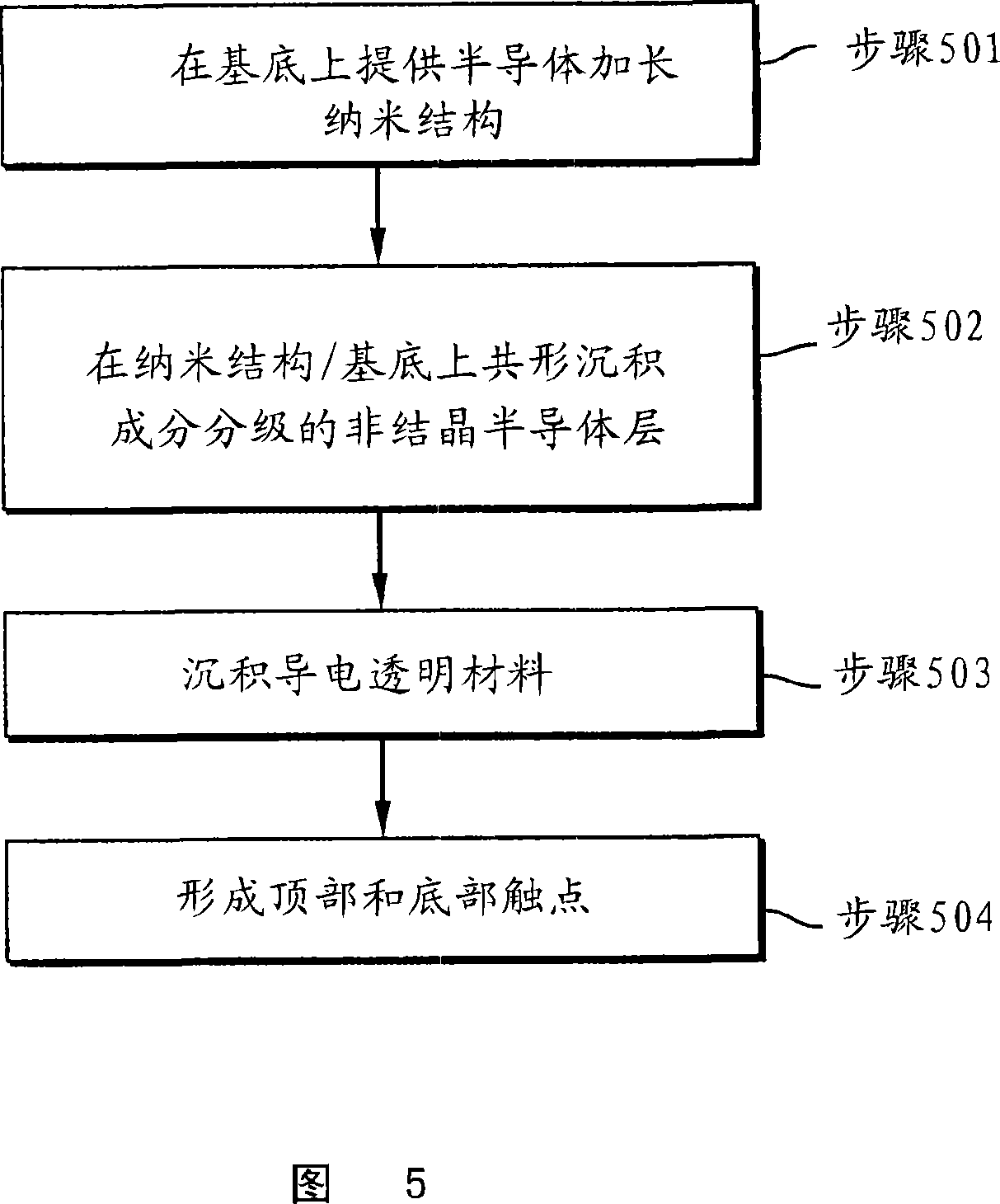

[0077] This example serves to demonstrate the process steps for fabricating compositionally graded hybrid nanowire optoelectronic devices according to certain embodiments of the present invention.

[0078] A film of silicon nanowires of one conductivity type on a glass, metal or semiconductor substrate is disposed in a plasma reaction chamber (eg, a plasma enhanced chemical phase deposition system). A vacuum pump removes the atmosphere from the chamber. The substrate to be treated is preheated to 120-240°C. A hydrogen plasma surface preparation step is performed prior to the deposition of the compositionally graded layer. H 2Introduce into the chamber at a flow rate of 50-500 sccm (standard cubic centimeters per minute). A throttle valve was used to maintain a constant process pressure in the range of 200-800 mTorr. The power density is 6-50mW / cm 2 A range of AC frequency input power is used to energize and maintain the plasma. The applied input power can be from 100kHz ...

Embodiment 2

[0083] This example serves to demonstrate illustrative applications in which optoelectronic device 100 (or variations thereof) may be used in accordance with certain embodiments of the present invention.

[0084] A photovoltaic module comprising a plurality of photovoltaic devices 100 is typically installed on a residential roof for grid-connected power generation. The modules are installed in several ways to achieve functional and sensory quality. The module now uses standard residential solar modules to provide electricity that can be stored or sold back to the utility for revenue. These solar cells can be cut to standard sizes and mounted into module frames, connected in series using standard solder-based interconnection methods, in some cases with bypass diodes to minimize shadowing effects. The all-glass substrate can be used directly in a framed module where the nanowires are grown on a transparent material, or the glass can be laminated and used as a module that does n...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com