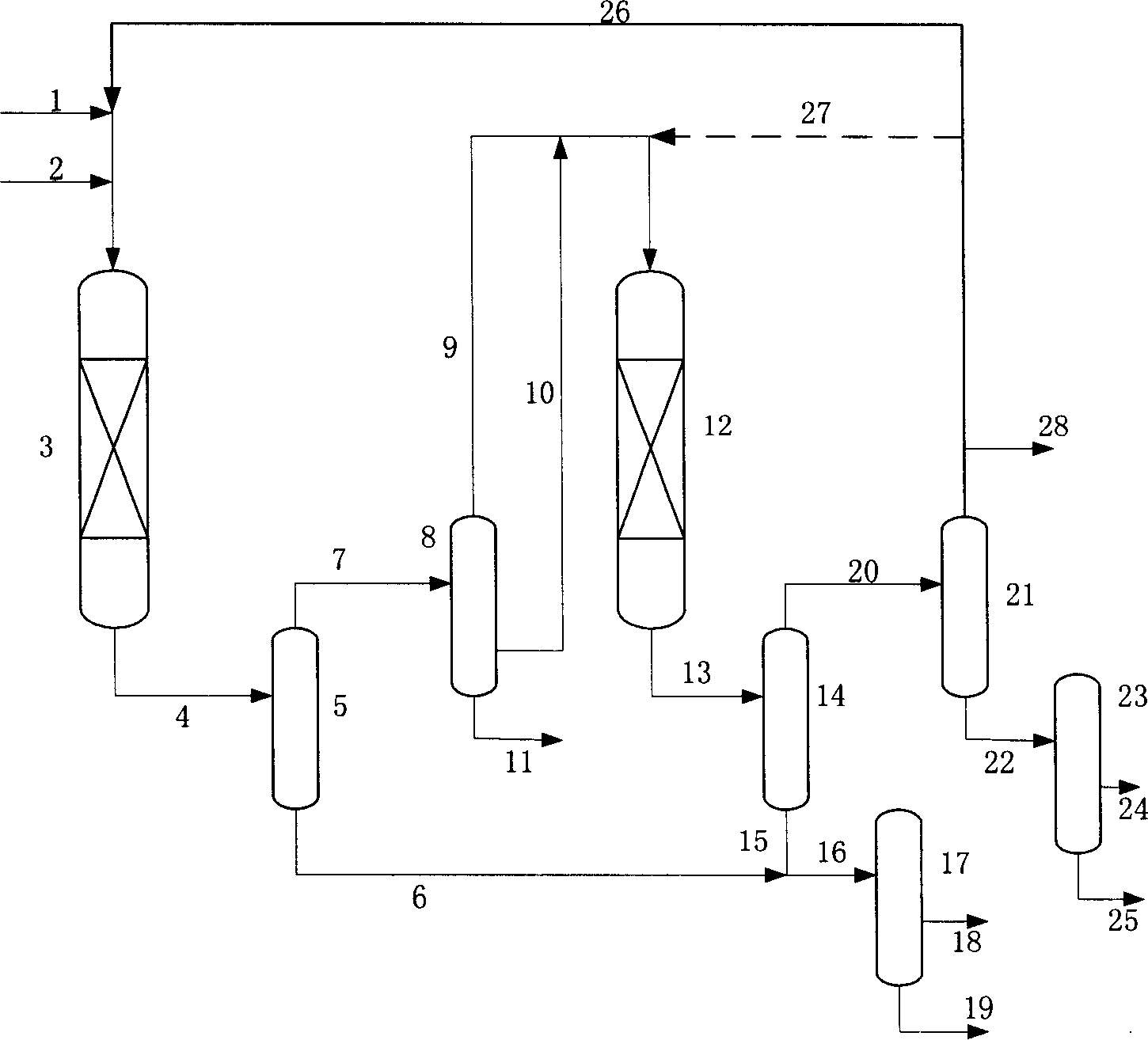

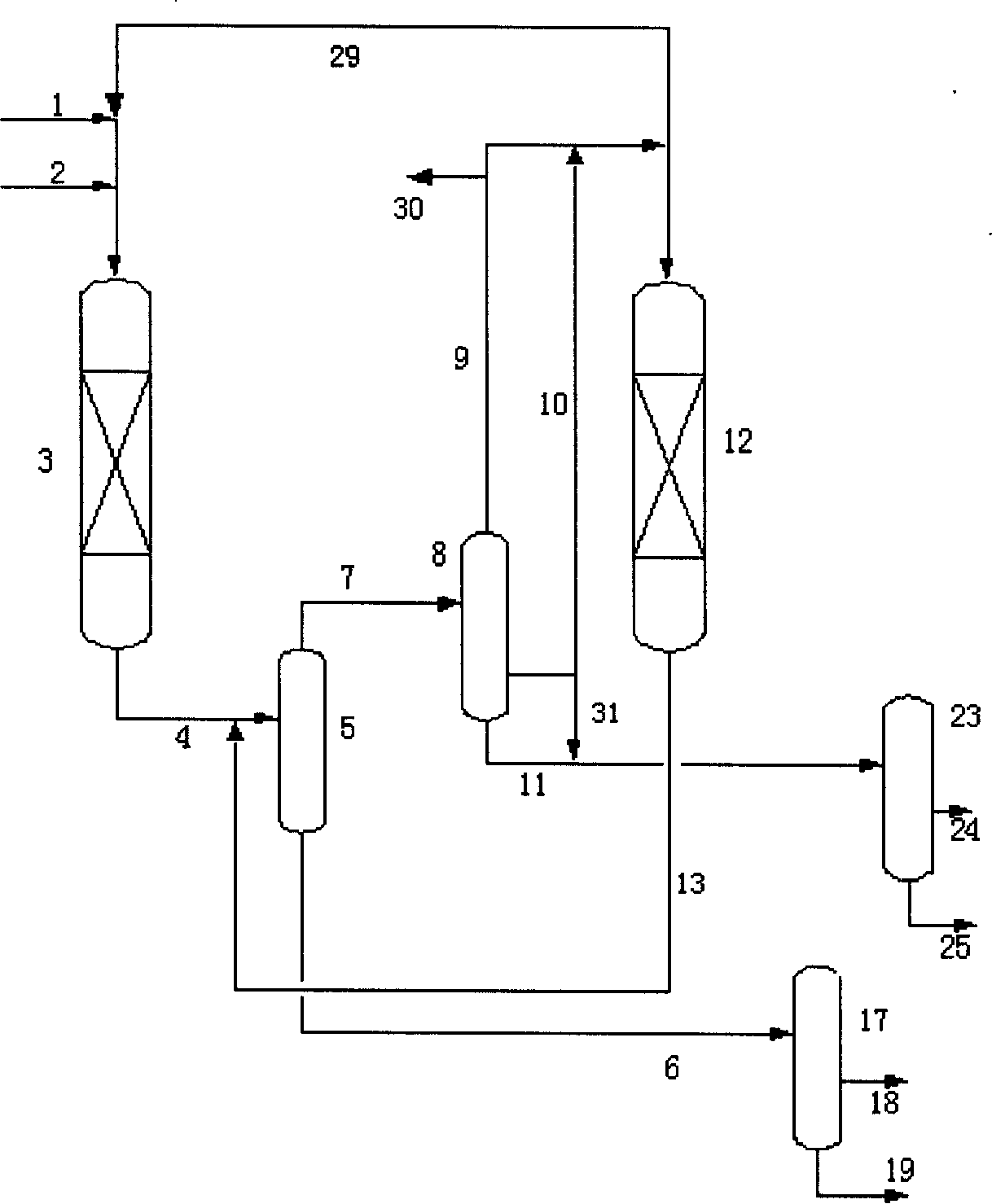

Fischer-Tropsch synthesis method for increasing liquid hydrocarbon selectivity

A technology of Fischer-Tropsch synthesis and liquid hydrocarbons, which is applied in the direction of producing hydrocarbons from carbon oxides. It can solve problems such as complexity, reduced processing capacity, and affecting operational stability, and achieves the effect of simple operation and improved selectivity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0026]Those skilled in the art know that, selected from Li, Na, K, Mg, Ca, Sr, Cu, Mo, Ta, W, Ru, Zr, Ti, REO, Re, Hf, Ce, Mn, Fe, V and noble metals (such as Pt, Pd, Rh, Ir, etc.) one or more additive components are commonly used additive components for Fischer-Tropsch synthesis catalysts known in the art. The catalyst according to the present invention preferably contains one or more selected from the above auxiliary components. When the catalyst contains the above auxiliary components, the preparation method of the catalyst further includes the step of introducing the auxiliary components into the catalyst. They may be introduced before, after, or simultaneously with the cobalt metal component. When the auxiliary components are introduced alone, the present invention has no limitation on the introduction method of the auxiliary. For example, the compound containing auxiliary components is formulated into an aqueous solution, and then impregnated by a conventional impregna...

Embodiment 1

[0036] Weigh 300g γ-Al 2 o 3 Carrier (product of Changling Catalyst Factory, particle size 16-26 mesh), the carrier is placed in a muffle furnace, roasted at 600 ° C for 3 hours, after cooling to room temperature, take 10 grams, and place it in a container filled with 30 milliliters of distilled water. Place in a beaker (specification: 50 ml) for 2 hours, then separate the water-absorbed carrier from water, record the water absorption volume, and calculate the water absorption rate to be 0.9 ml / g.

[0037] Weigh the above γ-Al 2 o 3 Carrier 30 grams, get 5.5 grams of cobalt nitrate and dissolve into the solution of 8.1 milliliters, under agitation, this solution adopts spray method to spray on described carrier (V L / V C =0.3), then baked at 120° C. for 4 hours in an oven, followed by sintering at 500° C. for 4 hours in a muffle furnace, and repeated the operation three times to obtain catalyst C1. The composition of C1 is listed in Table 1.

Embodiment 2

[0039] Weigh the γ-Al of Example 1 2 o 3 Carrier 30 grams, get 8.3 grams of cobalt nitrate and dissolve into the solution of 13.5 milliliters, under agitation, this solution adopts spray method to spray on above-mentioned carrier (V L / V C =0.5), then baked at 120° C. for 4 hours in an oven, followed by sintering at 500° C. for 4 hours in a muffle furnace, and repeated the operation twice to obtain catalyst C2. The composition of C2 is listed in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com