Phase control focusing ultrasound wave source device

A technology for focusing ultrasound and wave sources, applied in the field of ultrasound wave sources, can solve the problems of increased equipment complexity, increased number of transducer array elements, and high cost, and achieve the effects of avoiding damage to normal tissues, excellent focusing performance, and enhanced focusing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

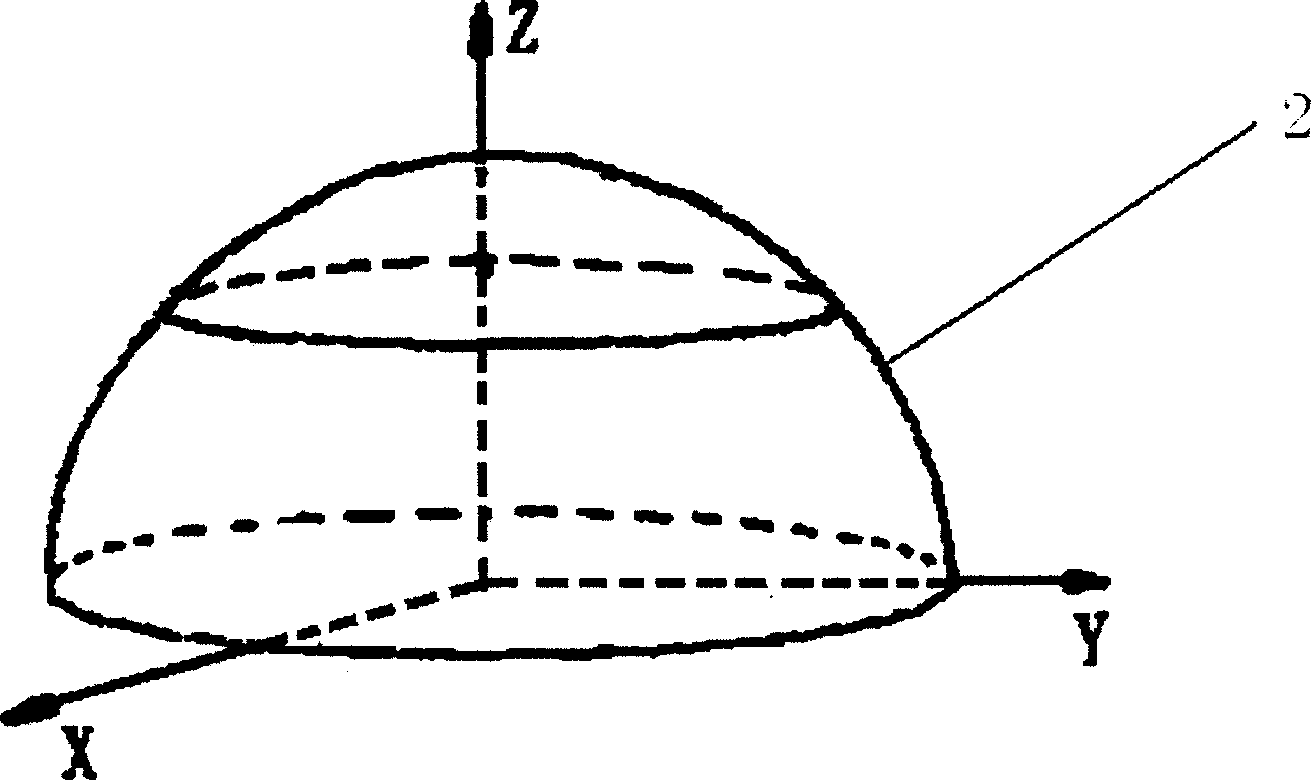

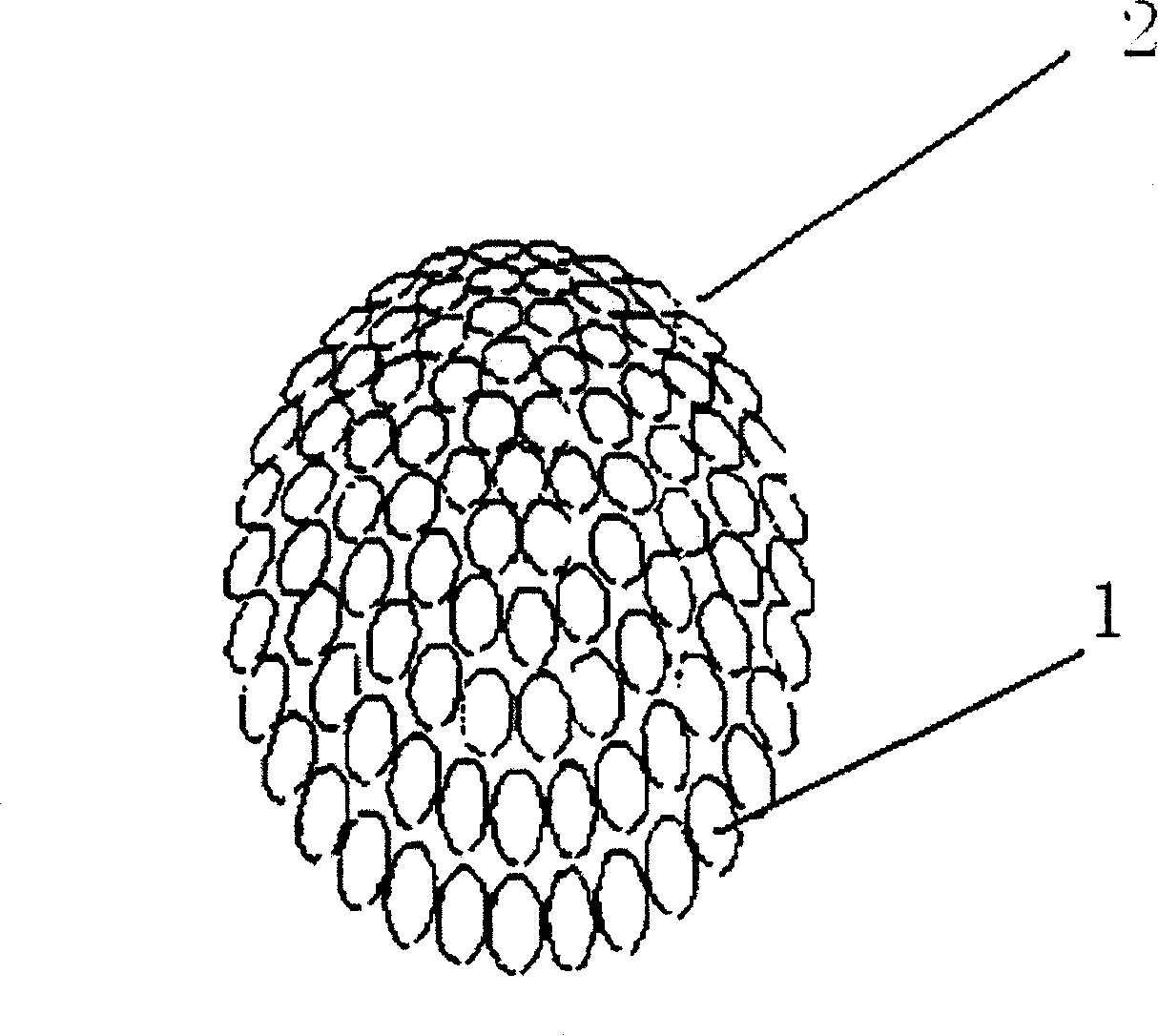

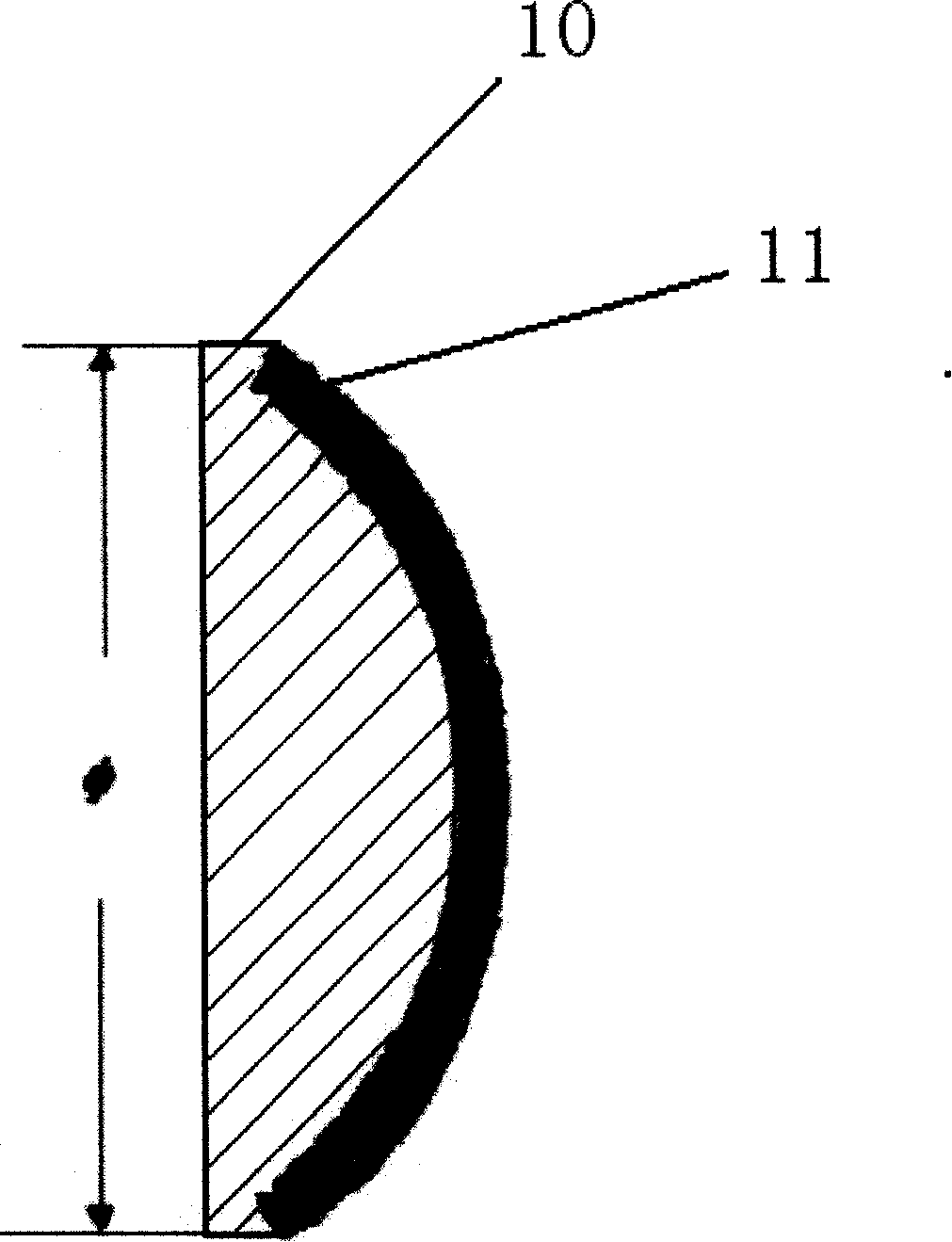

[0027] Referring to FIG. 1 , a source for phase-controlled focusing of ultrasonic waves includes a plurality of transducer array elements 1, such as 20, and a bearing part 2 that carries the transducer array elements 1, and the transducer array elements 1 It is cylindrical, the top is a piezoelectric wafer 11, and the bottom is a base 10. The base 10 and the piezoelectric wafer 11 are bonded as a whole by a glue-like adhesive. The bearing part 2 is concave spherical, and all the The transducer array element 1 is carried on the carrying member 2 so that all the piezoelectric wafers 11 are arranged in a concave spherical shape. The radius of the concave spherical surface is R=300mm, and the aperture angle is selected between 50° and 120°, such as 50°. The piezoelectric chip 11 is arc-shaped, so that the top of the transducer array element 1 is a circular convex surface.

[0028] The bearing part 2 can be made by conventional technology, such as using metal materials to make a s...

Embodiment 2

[0032] Referring to FIG. 1 , a source for phase-controlled focusing of ultrasonic waves includes a plurality of transducer array elements 1, such as 10, and a bearing member 2 carrying the transducer array elements 1, and the bearing member 2 is a concave spherical surface All the transducer array elements 1 are carried on the bearing part 2 so that all the piezoelectric wafers 11 are arranged in a concave spherical shape. The radius R of the concave spherical surface is 300 mm, and the aperture angle is selected between 50° and 120°, for example, 120°. The piezoelectric chip 11 is arc-shaped, so that the top of the transducer array element 1 is a circular concave surface.

[0033] refer to image 3 , the transducer array element 1 is cylindrical, and the diameter of the bottom surface is 5 mm to 20 mm, which is selected as 20 mm here. The base material is selected as a material with a lower density, such as a resin material, specifically 618 epoxy resin material, with a thi...

Embodiment 3

[0037] Referring to FIG. 1 , the carrying part 2 is in a concave spherical shape, and all the transducer array elements 1 are carried on the carrying part 2 so that all the piezoelectric wafers 11 are arranged in a concave spherical shape. The radius R of the concave spherical surface is 300 mm, and the aperture angle is selected between 50° and 120°, such as 100°.

[0038] refer to Figure 4 , the piezoelectric wafer 11 is a wafer with a circular plane, and an acoustic lens is bonded to the top of the piezoelectric wafer 11. The acoustic lens can be a concave lens or a convex lens. Taking the convex lens as an example here, the top of the transducer array element 1 is Round convex. The transducer array element 1 is cylindrical, and the diameter of the bottom surface is 5 mm to 20 mm, which is selected as 10 mm here. The base material is selected as a material with a low density, such as a resin material, such as 618 epoxy resin material, with a thickness of 2mm-10mm, such a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Radius | aaaaa | aaaaa |

| Bottom diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com